Maintenance and Inspection

To keep the voltage constant

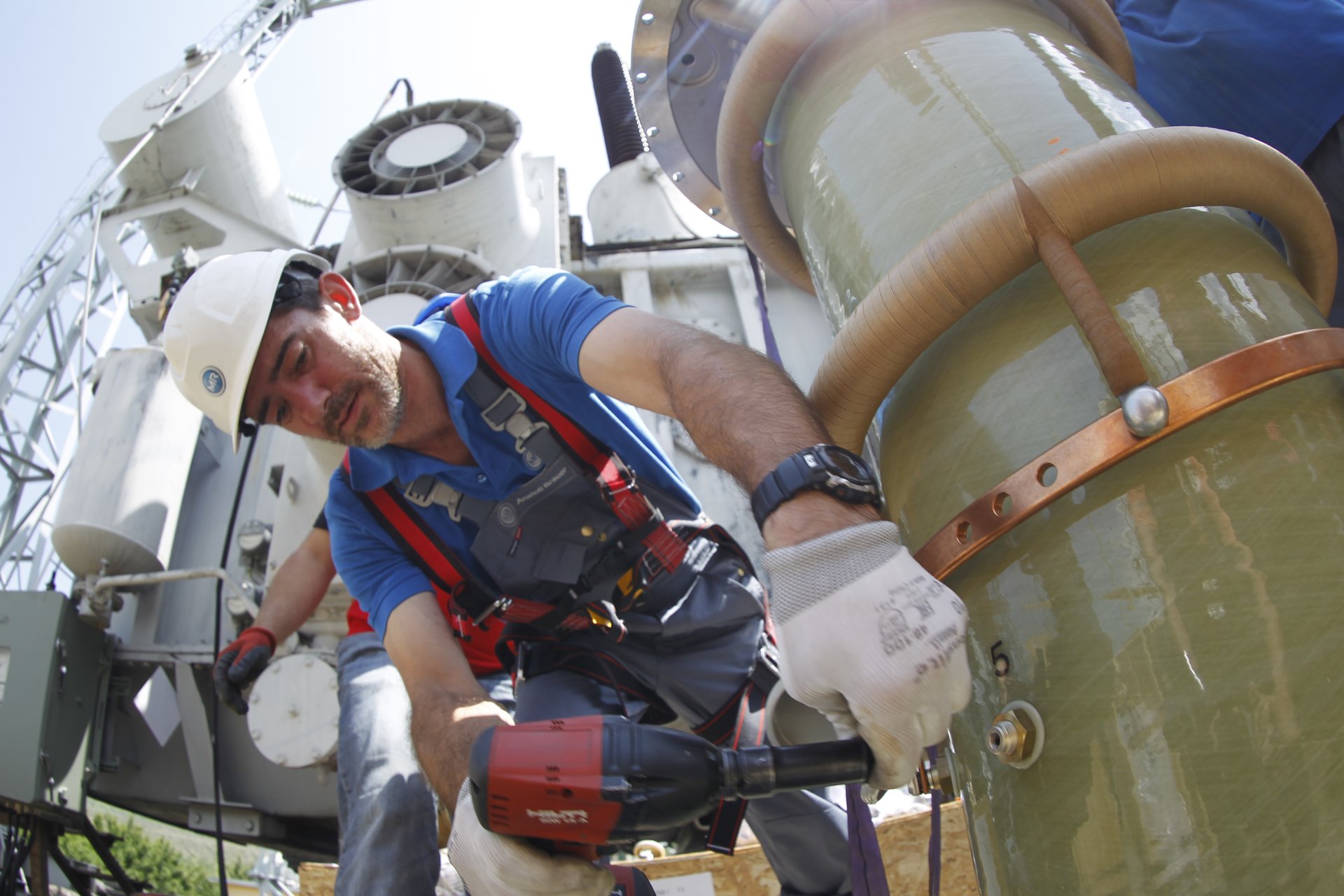

To ensure reliable operation of your power transformer, the on-load tap-changer must function properly. To ensure this, professional maintenance is required for every on-load tap-changer, whether oil or vacuum technology.

Use our TESSA® OLTC Premium Service for this purpose. With more than 6,000 on-load tap-changer maintenance operations per year, our specially trained and certified service technicians have unique field experience. A likewise uniquely dense network of 21 service branches worldwide also guarantees the rapid delivery of spare parts, as well as 24/7 accessibility.

Request online now on myReinhausen

myReinhausen

Your Advantages at a Glance

-

Trouble-free

Our OLTC service guarantees trouble-free operation

-

Up to date

With OEM parts your on-load tap-changer will be brought up to date

-

Safe

You receive a 24-month warranty on our service activities

-

Independent of manufacturer

Service for all types, brands and models of on-load tap-changers

-

Compliant

Our service is in accordance with DIN EN ISO 9001 and 14001, among others

-

Fast

We are usually on site within less than 24 hours

More Information

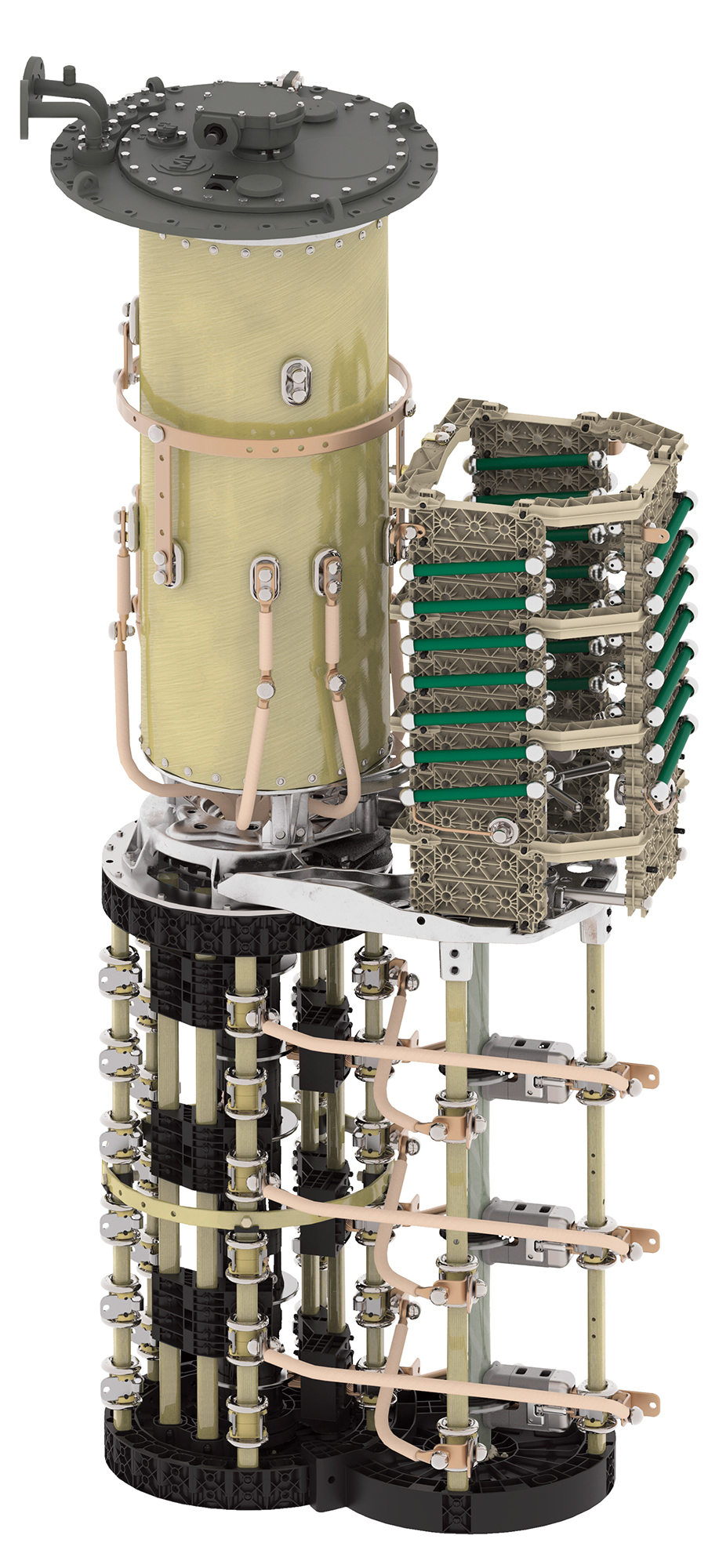

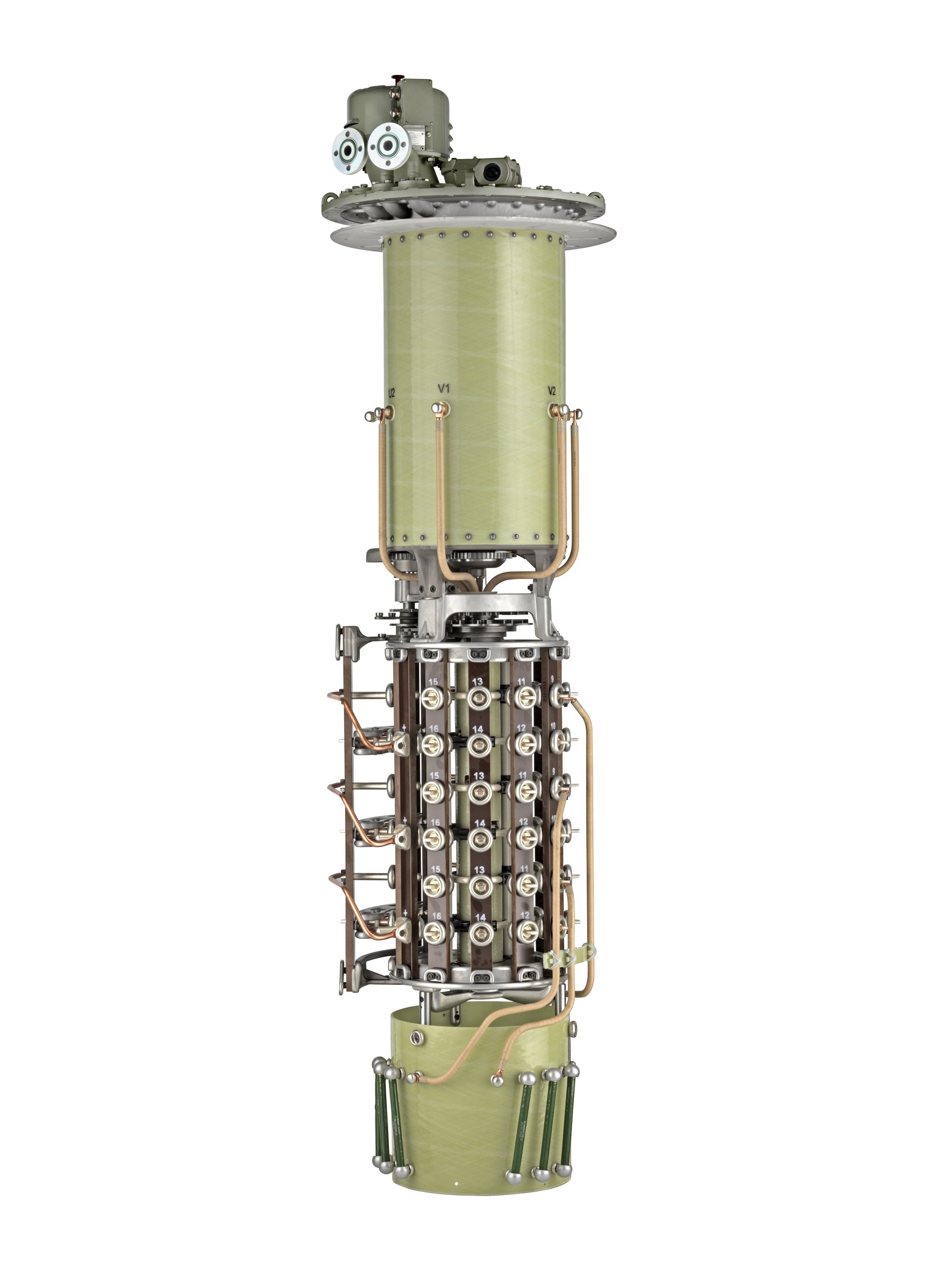

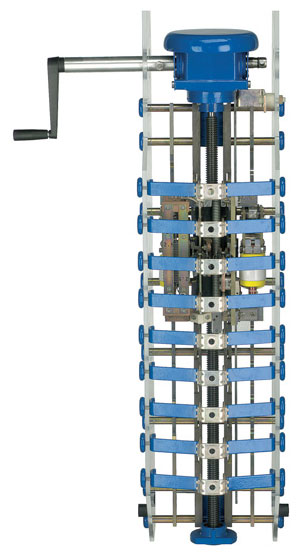

Our OILTAP® on-load tap-changer is characterized by its rugged design, versatile options for use and proven durability. Our oil on-load tap-changers have been in operation for many decades. Because of these long lifespans, the number of tap-change operations and time intervals representing critical maintenance criteria are being reached more and more frequently. Therefore, we offer various tools for the inspection and maintenance of OILTAP® on-load tap-changers.

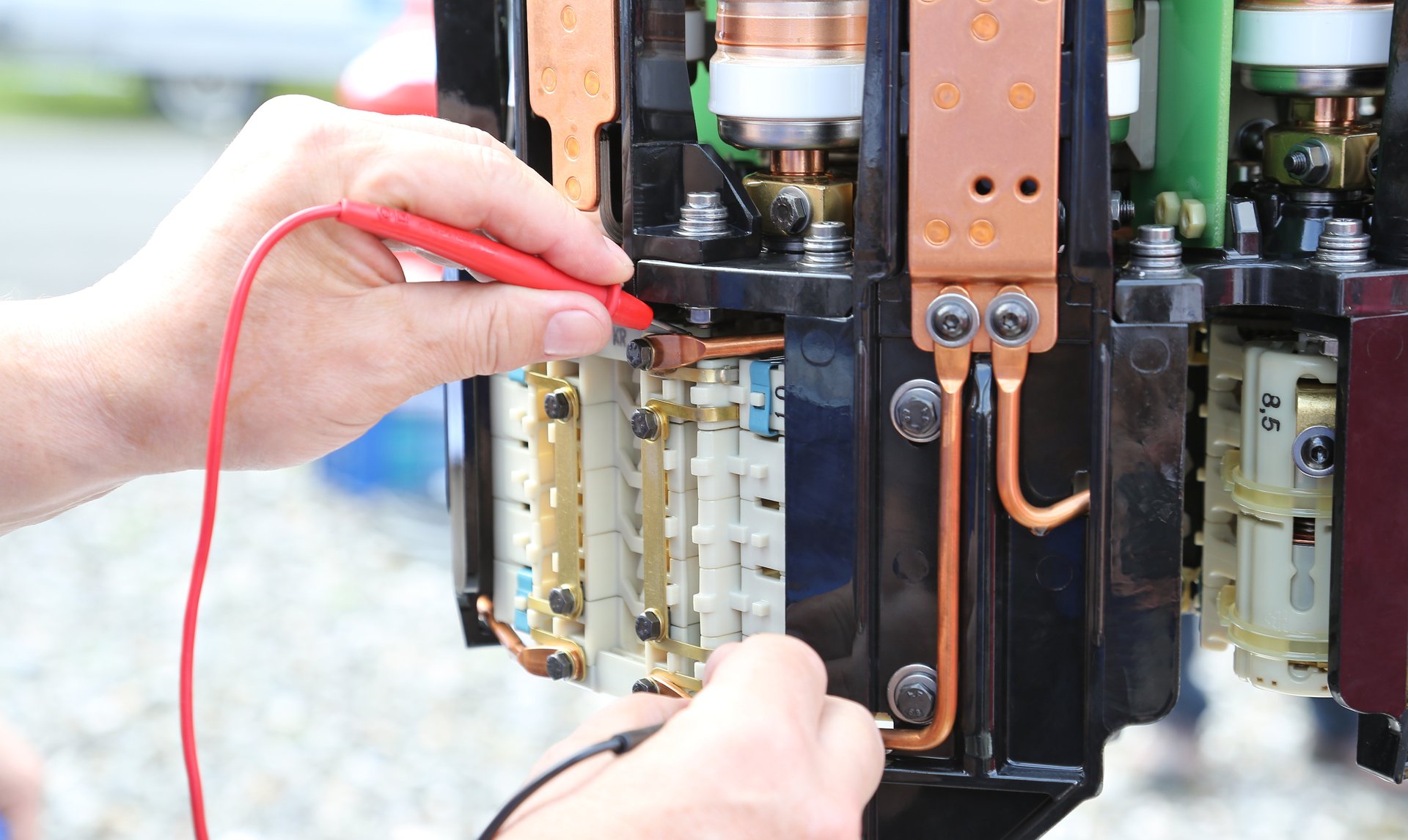

The inspection and maintenance work can be combined perfectly with electrical measurements for the on-load tap-changer. For oil-filled on-load tap-changers, the vibro-acoustic measurement (VAM) and dynamic resistance measurement (DRM) are available.

Our VACUTAP® on-load tap-changers are used in multiple high-end applications, such as in strategically important transformers for energy transmission grids or in heavy industry. For such critical applications, reliability, availability and safe operation must be ensured at all times. Therefore, we offer various tools in our portfolio for condition assessment and maintenance. Our all-inclusive package includes various tests, such as a dynamic resistance measurement, vibro-acoustic measurement and other diagnostic measurements (e.g. oil analysis and electrical measurements).

We offer the all-inclusive package! In addition to OEM spare parts and oil handling, we also provide two qualified service experts and a crane.

Your benefits:

1. Concentrate your resources on the core business

2. Reduce your overall expenses

3. Get the highest quality when outsourcing your service to MR

4. Can be combined with other services on the transformer

5. Pass on business risk to MR – 2-year warranty

6. Maintenance by truck, no matter the weather

We carry out maintenance on the following tap-changers: All types from Maschinenfabrik Reinhausen; Trafo Union/TUSA/AEG; Elin; Elprom/Hyundai Elprom; Westinghouse; General Electric/Canadian GE; Ferranti/Ferranti Packard; Siemens/Allis Chalmers; ABB/Asea/BBC/Waukesha SPX; Alstom; Mitsubishi, Toshiba; Fuji/Fuji-TU; Hitachi; Brush/ATL; McGraw Edison; Federal Pacific/Federal Pioneer; ZTR; Hawker Siddley; ACEC; other types of old tap-changers from former manufacturers

Inspection and maintenance work can be combined perfectly with electrical measurements for the on-load tap-changer. For the oil-filled on-load tap-changer, the vibro-acoustic measurements (VAM) and the dynamic resistance measurement (DRM) are available. For a vacuum on-load tap-changer, a combination of vibro-acoustic measurement (VAM), dynamic resistance measurement (DRM) and measurement of the vacuum tubes is offered.

In case of a necessary selector maintenance, the complete service can be supplied from one source:

- Pumping out the oil (with compensation by dry air) from the transformer into external tanks

- Opening or, if necessary, also insertion of manholes for access for maintenance

- Maintenance of the selectors in installed condition

- Sealing and closing of manholes

- Reconditioning of the oil (filtering, degassing, drying)

- Suction of the oil after a vacuum phase under vacuum or partial vacuum

- Bleeding of the transformer

- Oil sampling with analyses before and after maintenance.

Select language

Our OILTAP® on-load tap-changer is characterized by its rugged design, versatile options for use and proven durability. Our oil on-load tap-changers have been in operation for many decades. Because of these long lifespans, the number of tap-change operations and time intervals representing critical maintenance criteria are being reached more and more frequently. Therefore, we offer various tools for the inspection and maintenance of OILTAP® on-load tap-changers.

The inspection and maintenance work can be combined perfectly with electrical measurements for the on-load tap-changer. For oil-filled on-load tap-changers, the vibro-acoustic measurement (VAM) and dynamic resistance measurement (DRM) are available.

Our VACUTAP® on-load tap-changers are used in multiple high-end applications, such as in strategically important transformers for energy transmission grids or in heavy industry. For such critical applications, reliability, availability and safe operation must be ensured at all times. Therefore, we offer various tools in our portfolio for condition assessment and maintenance. Our all-inclusive package includes various tests, such as a dynamic resistance measurement, vibro-acoustic measurement and other diagnostic measurements (e.g. oil analysis and electrical measurements).

We offer the all-inclusive package! In addition to OEM spare parts and oil handling, we also provide two qualified service experts and a crane.

Your benefits:

1. Concentrate your resources on the core business

2. Reduce your overall expenses

3. Get the highest quality when outsourcing your service to MR

4. Can be combined with other services on the transformer

5. Pass on business risk to MR – 2-year warranty

6. Maintenance by truck, no matter the weather

We carry out maintenance on the following tap-changers: All types from Maschinenfabrik Reinhausen; Trafo Union/TUSA/AEG; Elin; Elprom/Hyundai Elprom; Westinghouse; General Electric/Canadian GE; Ferranti/Ferranti Packard; Siemens/Allis Chalmers; ABB/Asea/BBC/Waukesha SPX; Alstom; Mitsubishi, Toshiba; Fuji/Fuji-TU; Hitachi; Brush/ATL; McGraw Edison; Federal Pacific/Federal Pioneer; ZTR; Hawker Siddley; ACEC; other types of old tap-changers from former manufacturers

Inspection and maintenance work can be combined perfectly with electrical measurements for the on-load tap-changer. For the oil-filled on-load tap-changer, the vibro-acoustic measurements (VAM) and the dynamic resistance measurement (DRM) are available. For a vacuum on-load tap-changer, a combination of vibro-acoustic measurement (VAM), dynamic resistance measurement (DRM) and measurement of the vacuum tubes is offered.

In case of a necessary selector maintenance, the complete service can be supplied from one source:

- Pumping out the oil (with compensation by dry air) from the transformer into external tanks

- Opening or, if necessary, also insertion of manholes for access for maintenance

- Maintenance of the selectors in installed condition

- Sealing and closing of manholes

- Reconditioning of the oil (filtering, degassing, drying)

- Suction of the oil after a vacuum phase under vacuum or partial vacuum

- Bleeding of the transformer

- Oil sampling with analyses before and after maintenance.

Select language

48 hours of on-load tap-changer maintenance in Turkish steelworks