All around the world, grid operators are being confronted with the same challenge: the fact that their equipment is reaching old age. It is no longer uncommon to see power transformers with a service life of 50 years or more. Therefore, there are questions that every grid operator is faced with: What condition is my fleet in? How long will our transformers last, and when will we have to invest in new ones? This situation is aggravated by fluctuating, higher loads resulting from renewable energy sources that increasingly push crucial transformers that are needed to ensure a stable power supply to their limits.

-

Impulses

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

- Lifetime optimization

- Power supply in industry

- Globalization

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

-

Lifetime optimization

-

Power supply in industry

-

Globalization

Impulses - Portfolio

-

Career

Career

-

Company

Company

Clever fleet management for transformers

Using the TESSA® FLEETSCAN 2D analysis system, asset and service managers always have an overview of the condition of their transformers, making it easier to plan maintenance, updates and investments.

Clever fleet management for transformers

Using the TESSA® FLEETSCAN 2D analysis system, asset and service managers always have an overview of the condition of their transformers, making it easier to plan maintenance, updates and investments.

That is why Reinhausen developed a condition-based method to identify transformers in critical condition at an early stage: TESSA® FLEETSCAN 2D. The system is based on a two-dimensional assessment matrix. First, the likelihood of functions failing is calculated in order to model the reliability of the fleet. The second dimension then considers the loss-of-life and is important for making long-term investment decisions.

Reinhausen designed TESSA® FLEETSCAN 2D as a manufacturer-independent assessment tool. This means it can offer all transformer fleet operators a lean solution for keeping their fleet up and running. This is how it works:

1. Collecting condition data at the transformer

1. Collecting condition data at the transformer

A sufficient database is essential to carry out the condition assessment. To keep failure times and assessment work to a minimum, TESSA® FLEETSCAN 2D includes three test stages. Depending on how detailed the assessment needs to be, not all three stages have to be carried out. Transformer data is already available in many cases, so the work involved in recording the data is minimal.

In the first stage, the operator provides the data which is already available. Examples include the master data of the transformers, measurements that have already been carried out and maintenance history information. The next stage involves an on-site appraisal which is carried out during operation. In the visual inspection, an MR expert uses a checklist to examine the transformer for signs of corrosion, leaks and visible damage to the bushings and fans. They also carry out infrared thermography and a complete oil analysis. If, after the first two stages, there are any indications of more significant damage, MR performs targeted testing while taking extensive measurements in the third stage. These include dynamic resistance and partial discharge measurements and require the transformer to be taken off the grid.

2. Managing and accessing transformer data online

2. Managing and accessing transformer data online

TESSA® FLEETSCAN 2D provides the option to save all collected data in a clear overview using browser-based software. This allows grid operators to retrieve all collected information and assessments of all equipment for any transformer in the fleet at any time.

3. Condition analysis of the transformers

3. Condition analysis of the transformers

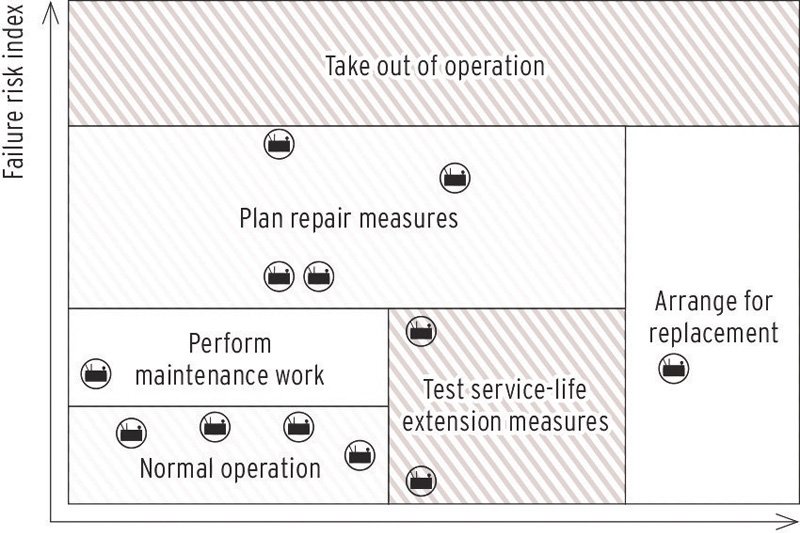

After the data has been recorded, it is time to move on to the core element of TESSA® FLEETSCAN 2D: the evaluation. Using an algorithm developed by MR and the University of Wuppertal, the condition analysis is carried out in two indexes: the failure risk index and the loss-of-life index. The failure risk index measures the likelihood of functions failing. These values provide important reference points for the maintenance strategy, which is crucial for the OpEx budget. The loss-of-life index is a key variable when making long-term investment decisions, and is therefore relevant for the CapEx budget.

The results of the two indexes are transferred into an x/y diagram for the assessment. The condition of the fleet can thus be visualized simply: The more transformers located in the quadrants near the origin, the better the condition of the fleet, and vice versa.

4. Recommendations for the transformer fleet

Once the assessment is complete, an MR expert checks the results and the plausibility of the data and offers recommendations. The grid operator will then receive a comprehensive report which they can use to derive the measures, maintenance tasks and investment decisions that need to be taken. The service life of the fleet can be increased by implementing targeted measures, without having to make a huge investment. Depending on the condition of the fleet, MR recommends that the TESSA® FLEETSCAN 2D assessment be repeated every three to five years.

„The TESSA® FLEETSCAN 2D method supports us in making operational and strategic decisions in Asset Management.“

Martin Hentschel, Stadtwerke Mosbach GmbH

TESSA® FLEETSCAN 2D – Clever fleet management at a glance

- Two-dimensional condition assessment for asset managers and service managers

- Service and asset managers obtain a clear overview of the condition of their fleet, allowing them to plan their OpEx and CapEx budgets effectively.

- Central document management with permanent access using the TESSA® FLEETSCAN 2D web application

- TESSA® FLEETSCAN 2D and detailed documentation help grid operators meet the specifications from the ISO 55000 process.

We are here for you. Wherever you are.

Looking for the right contact partner?

Do you have a concern, but don't know whom you should contact? You will find that information in our contact overview. In the event of any technical disturbances, our 24/7 support is always at your disposal.

Welcome to myReinhausen

myReinhausen is MR's central, digital customer platform. On myReinhausen, customers can access customer-specific MR information as well as numerous free features related to the MR portfolio.

myReinhausenJoin Reinhausen family

Find your ideal job quickly!

Check our vacancies here. Apply today and contribute at the world market leader in energy technology keeping the energy supply stable in the future.