Canadian transformer manufacturer PSI Transformers received the order to replace a transformer for a hydropower station. The new transformer had to be able to switch between one transmission line at 250 kV and another at 143 kV. The test voltage required was a massive 1,000 kV. "To build a tap-changer for such extreme requirements, from our point of view, there was only one supplier we wanted to work with – and that was Reinhausen," states George Partyka Jr., Vice President of PTI Transformers.

-

Impulses

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

- Lifetime optimization

- Power supply in industry

- Globalization

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

-

Lifetime optimization

-

Power supply in industry

-

Globalization

Impulses - Portfolio

-

Career

Career

-

Company

Company

Oversized de-energized tap-changers

If a de-energized tap-changer has to maintain a huge test voltage of 1,000 kV and switch 112 kV in a single step, you need real experts. That is why Canadian transformer manufacturer PTI came to Reinhausen.

Oversized de-energized tap-changers

If a de-energized tap-changer has to maintain a huge test voltage of 1,000 kV and switch 112 kV in a single step, you need real experts. That is why Canadian transformer manufacturer PTI came to Reinhausen.

„The power of the transformer depends on the tap changer. Therefore, we needed to work closely with our developers.“

George Partyka Jr., Vice President at PTI Transformers

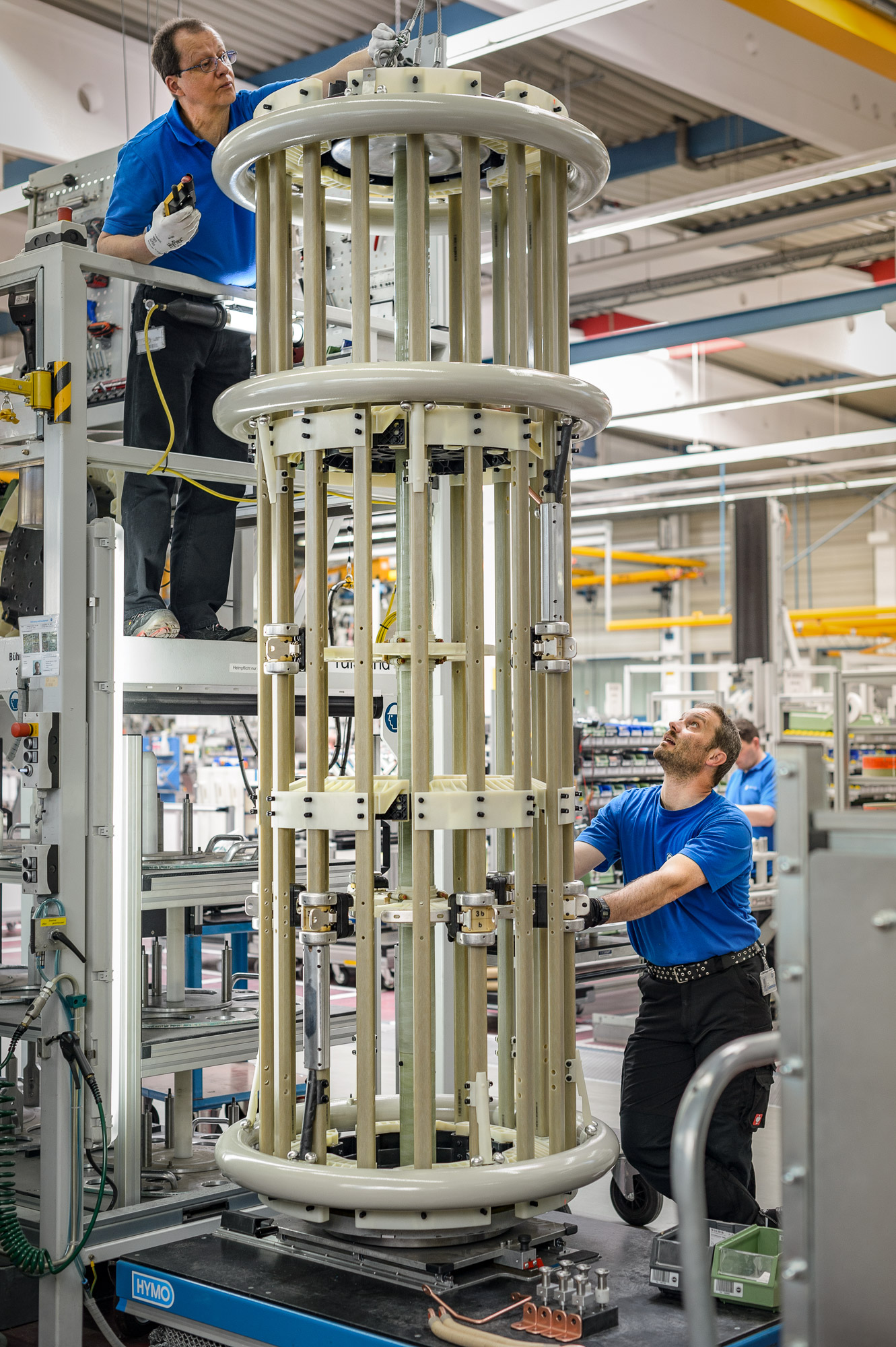

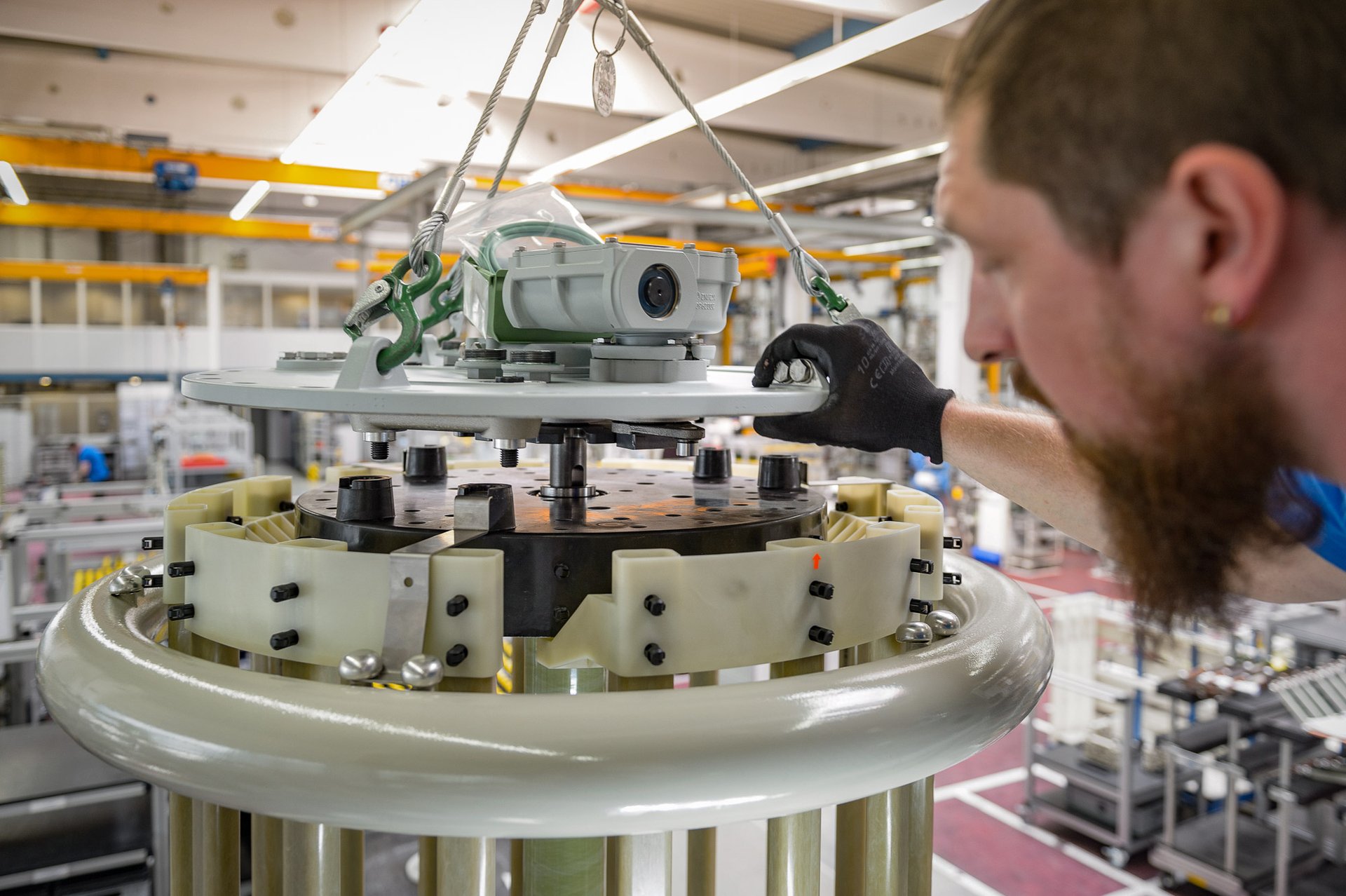

There was no doubt at all in the mind of the Canadian manager that Reinhausen could bring its technical know-how and expertise to bear in building a de-energized tap-changer to this specification. The largest de-energized tap-changers in Reinhausen's portfolio measure three meters in length and one meter in diameter. Producing equipment on this scale has put the experts from Regensburg on the world map. No other supplier includes tap changers of this size as standard in its portfolio. But it was obvious that it wouldn't be easy. Karl-Heinz Sperger, who led the project on the Reinhausen side, was also aware of this. "While our de-energized tap-changers are huge, there are still certain restrictions on the space we have to work with, and we can't just increase the distance between the contacts as much as we'd like. That made the physics of this project and what was technically feasible a real test."

Switching step of 112 kV at 1,000 kV test voltage

Another significant factor contributing to the complexity of the project was the transmission ratio of 1:1.78. Switching 143 kV to 250 kV in a single step requires six high-voltage winding strands – for each phase. For PTI Transformers, this meant housing 18 windings and three of the massive tap changers within the transformer, something which, as PTI Transformers Manager Partyka explained, was only possible with Reinhausen's support. "The transformer power is highly dependent on the tap-changer capacity, so the development departments working on the tap-changer design and the transformer design had to work together very closely. Only as a team was it possible for us to coordinate the winding configuration with the special design of the tap-changer."

The physical limits

long

in diameter

test voltage

in one switching step

Check in the test lab

The PTI Transformers and Reinhausen experts completed this complex development task in a mere three months, meaning that the order was placed and the de-energized tap-changers could go into production in February of 2019. The technicians were then able to construct the three special pieces of equipment in just five days. "Because we insist on delivering 100% quality, the tap changers were then sent to our test laboratory," says Sperger, an electrical engineer himself. There, it was found that the engineers had delivered on their promises.

Our customer PTI Transformers

Founded in 1989 and headquartered in the city of Regina, PTI Transformers is one of Canada's leading companies specializing in transformer technology. PTI Transformers employs around 300 people at production sites in Regina and Winnipeg, Canada, and is certified in accordance with ISO 9001:2015. The company prides itself on delivering not only high-quality products, but also customized services for all aspects of transformers.

We are here for you. Wherever you are.

Looking for the right contact partner?

Do you have a concern, but don't know whom you should contact? You will find that information in our contact overview. In the event of any technical disturbances, our 24/7 support is always at your disposal.

Welcome to myReinhausen

myReinhausen is MR's central, digital customer platform. On myReinhausen, customers can access customer-specific MR information as well as numerous free features related to the MR portfolio.

myReinhausenJoin Reinhausen family

Find your ideal job quickly!

Check our vacancies here. Apply today and contribute at the world market leader in energy technology keeping the energy supply stable in the future.