The power grids of industrial plants have changed dramatically over the past two decades. In the past, the primary concern was still reactive power compensation to ensure that the voltage would remain stable and transmission losses would be reduced. But since the 2000s, an increasing number of frequency-controlled drives are being used in machines. These machines are very energy-efficient, but the power electronics have negative impacts on the grid. The more these types of drives are used, the more harmonics occur.

-

Impulses

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

- Lifetime optimization

- Power supply in industry

- Globalization

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

-

Lifetime optimization

-

Power supply in industry

-

Globalization

Impulses - Portfolio

-

Career

Career

-

Company

Company

Putting an End to Harmonics in Industries

Harmonics can bring entire industrial operations to a halt. With the modular system "Total Harmonic Solution", Reinhausen Power Quality provides a useful tool to combat these unwanted grid disturbances.

Putting an End to Harmonics in Industries

Harmonics can bring entire industrial operations to a halt. With the modular system "Total Harmonic Solution", Reinhausen Power Quality provides a useful tool to combat these unwanted grid disturbances.

Harmonics are waves with a frequency many times higher than the fundamental frequency. For the electrical voltage, this frequency has a sinusoidal curve. But only in ideal cases. This is because interference factors, such as the frequency-controlled drive, override and distort this ideal sinusoidal curve with other sinusoidal waves. This causes harmonics, which in turn have negative impacts on the electrical equipment – and it becomes a vicious cycle. Holger Kretzschmar from Reinhausen Power Quality explains. "Initially, the fifth harmonic was the one that caused the most problems. This was eliminated with passive filters. But as the number of frequency-controlled drives increased, more harmonics appeared, from the seventh, through the eleventh, and up to the 51st harmonic. Active filters are needed to get these under control." Simply put, passive filters act like a resistor that dissipates the harmonic, while active filters eliminate it by emitting waves in the opposite direction.

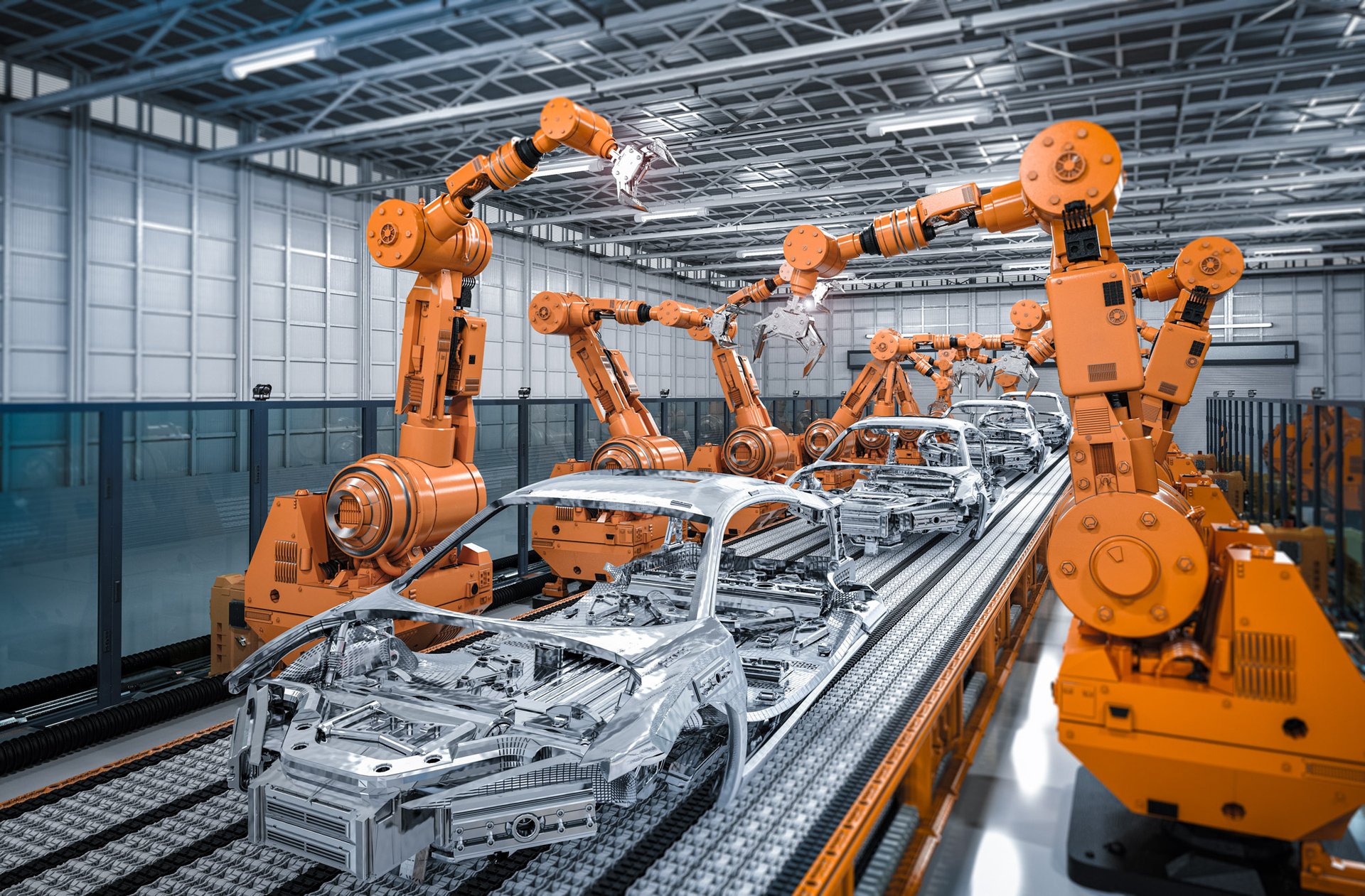

Example 1: Automotive industry

Example 1: Automotive industry

Without power electronics, it would be impossible to manufacture mass-produced, highly automated vehicles. But these production lines, operated by robots, feed various frequencies of harmonics into the power distribution system. This leads to heating, and thus causes the electrical equipment to age prematurely. In the worst case, this can potentially lead to the failure of electronic controls, and therefore production, not to mention overloads in transformers and cables. In addition, the power consumption increases due to the harmonics. Active filters help to safeguard production, extend the service life of machines, and reduce power consumption in production.

Supraharmonics is the new threat

A relatively new source of interference involves what are known as supraharmonics, with oscillations in higher frequency ranges from two to nine kilohertz. The origins of these are called active front ends (AFEs), meaning frequency inverters, which will be applied much more often in the future. In the past, supraharmonics never bothered anyone. A die-cutting machine is robust enough to endure them, but modern loads, such as LED lights, are increasingly becoming more sensitive. Small types of power electronics break down quickly at higher oscillations. "This is why we wanted to develop a filter solution that would eliminate problems with harmonics and supraharmonics once and for all. In real life, such filter systems are often complex and oversized, which turns people many away. Therefore, our solution should be simple and tough," says Kretzschmar.

Example 2: Water management

Example 2: Water management

The goal of the water management industry is to achieve a high level of energy efficiency. For example, more and more wastewater treatment plants are integrating power generation systems with frequency converters (for example, solar) to run electric pumps, which in turn are increasingly being equipped with frequency converters themselves. Interference from harmonics is practically inevitable.

„This is why we wanted to develop a filter solution that would eliminate all interfering harmonics once and for all.“

Holger Kretzschmar

By developing the Total Harmonic Solution, the experts at Powerquality have created a modular system solution featuring passive and active filters as well as SHU filters for the supraharmonics. Operators can decide which modules they actually need, so they can assemble a both standardized and customized filter solution and retrofit it at any time. The special feature of the solution is the device software. It measures the harmonics, and the algorithm continuously evaluates the interference levels and counteracts them automatically so that the defined limit values are not exceeded. Experience from the field has also been incorporated into the programming. The system regulates itself automatically and filters exactly whatever is needed. If an operation changes its production line and the power grid changes as a result, that is also no problem. The new parameterization runs on its own, without any service technician having to physically go to it.

One Solution for Everything

The Total Harmonic Solution system solution features three components that can be combined as needed:

- GRIDCON® CHF for the 5th harmonic

- GRIDCON® ACF for the 3rd to 51st harmonic

- SHU filter modules for the supraharmonics in the higher frequency range up to 10 kHz

The software is programmed in such a way that the control adapts itself independently and with high precision to the particular power grid and its specific oscillations. Installation is extremely simple and is based on the plug-and-play principle. No complex parameterization is required.

We are here for you. Wherever you are.

Looking for the right contact partner?

Do you have a concern, but don't know whom you should contact? You will find that information in our contact overview. In the event of any technical disturbances, our 24/7 support is always at your disposal.

Welcome to myReinhausen

myReinhausen is MR's central, digital customer platform. On myReinhausen, customers can access customer-specific MR information as well as numerous free features related to the MR portfolio.

myReinhausenJoin Reinhausen family

Find your ideal job quickly!

Check our vacancies here. Apply today and contribute at the world market leader in energy technology keeping the energy supply stable in the future.