A power transformer that has been in use for many years is like a person: It ages and needs more regular health checkups. Over time, this cost adds up – especially if the transformer requires replacement parts that are no longer available or are hard to come by.

Retrofit: Breathing new life into old transformers thanks to new tap changers

Reinhausen modernizes old transformers with new tap changers, thus extending their service life. This is the case for grid operator Elia in Belgium.

Retrofit: Breathing new life into old transformers thanks to new tap changers

Reinhausen modernizes old transformers with new tap changers, thus extending their service life. This is the case for grid operator Elia in Belgium.

Belgian grid operator Elia was facing this exact problem. A transformer in its primary substation in Zaventem, a suburb of Brussels, had come into old age and the tap changer inside was worn. Since the manufacturer had ceased production back in 1989, replacement parts were increasingly scarce and expensive. But a new transformer was out of the question for Elia. After all, all the other components were still functioning without problems. So the grid operator commissioned service provider Maintenance Partners, together with the Reinhausen Luxemburg (RLU) subsidiary, to replace the old tap changer with a new one in early May, thus future-proofing the transformer. The entire conversion took only ten business days. Sebastian Hölzer, Managing Director of RLU, explains how the team got it done in six steps.

1. Collecting operating data using the transformer

Every power transformer is different. For that reason, we first compiled all the information from the transformer book and the nameplates. This included the power of the transformer, the line and isolation voltages and the supply voltage for the motor-drive unit. Furthermore, we were able to use this data to determine how much current is supposed to flow through the new tap changer and how the electrical wiring would look.

2. Selecting components for the tap changer retrofit

2. Selecting components for the tap changer retrofit

With this preliminary knowledge, it was clear that only a three-phase VACUTAP® VM® 500 with Y connection could be a possible tap changer, as it hardly needs any maintenance compared to the old OILTAP® tap changer. In addition, our experts in Regensburg explained how the adapter flange needed to look for the switch head, so that we could insert the new tap changer into the opening of the old one.

We also specified the motor-drive unit equipment together with Elia. We then produced the tap changer and the drive in-house. A third-party steel manufacturer produced the adapter flange.

3. Preparing the transformer for replacement

Before replacing the tap changer, the service provider Maintenance Partners spent two days preparing the transformer. The transformer first needed to be switched off and grounded. Oil was then drained from the transformer tank and manholes were cut in the 15-millimeter thick transformer wall. This allowed our technicians to climb inside the cramped transformer tank in full-body suits and start the replacement work.

4. Installation of the VACUTAP® VM® 500 vacuum tap-changer

4. Installation of the VACUTAP® VM® 500 vacuum tap-changer

Now, the old tap changer needed to be removed. To do so, we cut open the cover using a blow torch and lifted the tap changer out of the transformer tank using a crane. We were then able to bring in the oil compartment of the new tap-changer, along with diverter switch insert, and position the selector.

Then, we connected the selector in the transformer with the tap winding and to the old supply lines via individually adjusted cables. Finally, the motor-drive unit and the linkage from the tap changer to the drive were attached.

„In addition to the quality of the tap changer, the quality of the replacement work is also of critical importance.“

5. Testing the transformer and the tap changer

5. Testing the transformer and the tap changer

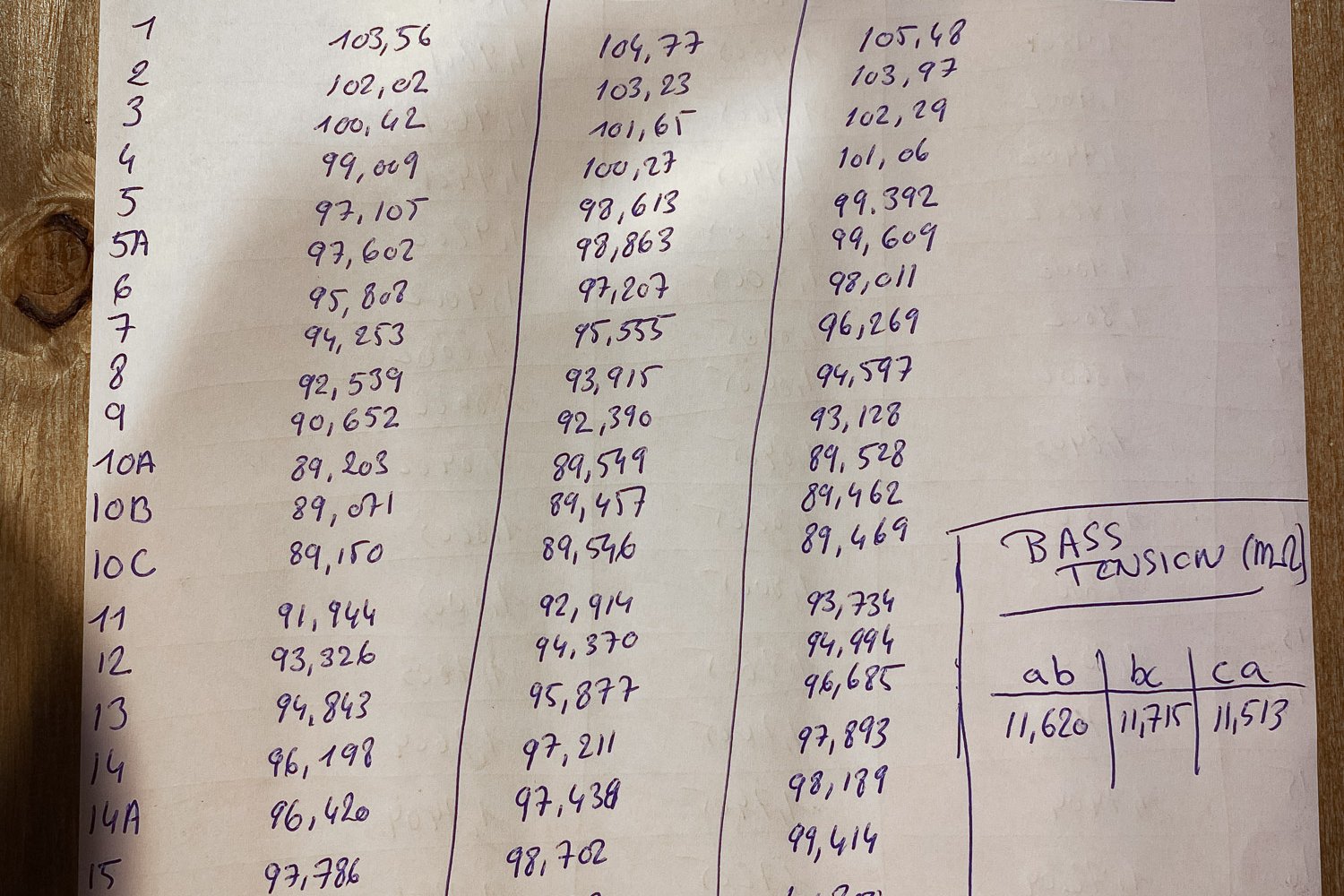

The next step was testing. This meant that experts from Maintenance Partners measured the transmission ratio at low voltage to see whether the tap changer stepped down the voltage correctly. This allowed us to be able to ensure that all supply lines were attached to the right points on the selector. Measurements of the resistance and isolation took place later.

6. Commissioning: Reconnecting the transformer to the power grid

This concluded the work onsite. Maintenance Partners closed the transformer tank back up and filled it with oil. Then, the oil was treated – in other words, dried, degassed and cleaned to remove contamination particles. This meant that the filled transformer needed to be connected to a processing system for several days. Afterwards, we handed the transformer over to Elia and, after a two-day no-load test, it was back online.