History

So many firsts!

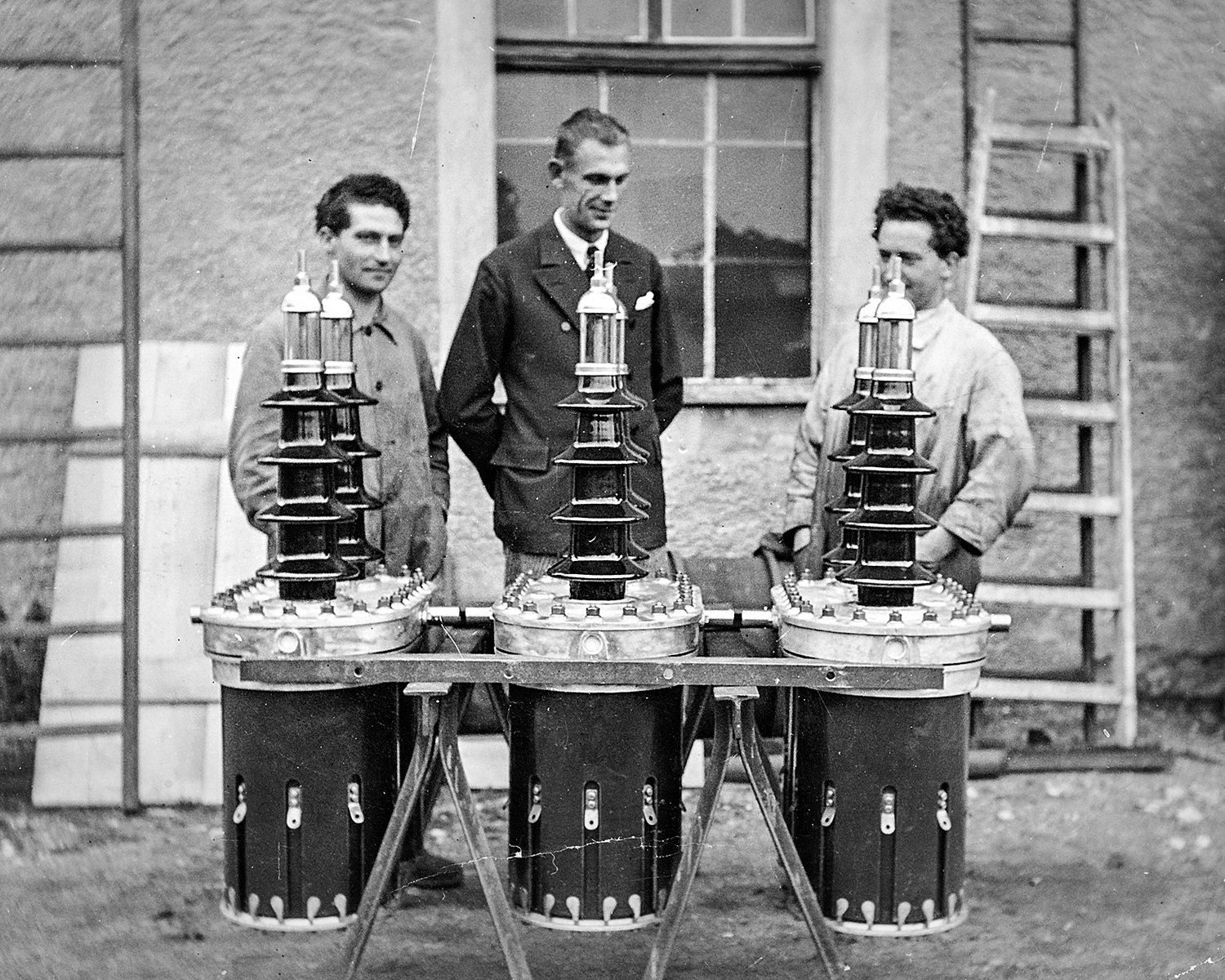

Reinhausen has systematically made a name for itself on the market through its innovations. Since the Scheubeck brothers produced the first prototype on-load tap-changer for Dr. Jansen in 1929, the company has been a driving force in the field of transformer developments.

1929 First on-load tap-changer based on the resistor principle

1929 First on-load tap-changer based on the resistor principle

In the 1920s, energy suppliers were calling for a way to regulate voltage more quickly. Transformers still had to be taken off the grid in order to change the transmission ratio. Was there a way to switch under load? Dr. Jansen had the idea, and Maschinenfabrik Reinhausen had the skills to put it into practice. The result was the world’s first prototype for a high-speed resistor-type tap-changer for interruption-free switching under load.

Patent application: in 1928 and 1929, three patents were published / pecial feature: 14 operating positions with change-over selector, max. 1.1 kV

1933

First tap changer in "tube design" (selector switch principle)

1933

First tap changer in "tube design" (selector switch principle)

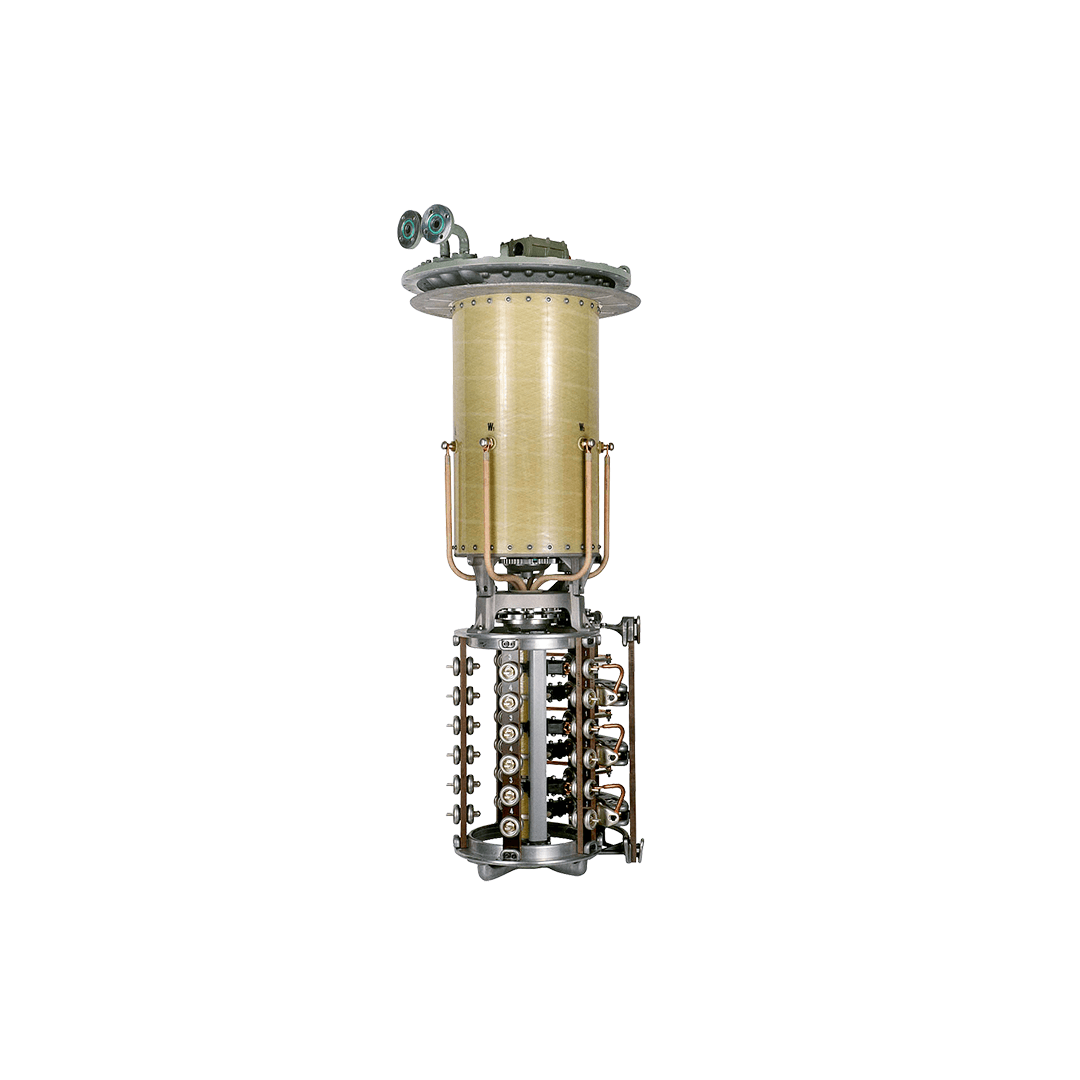

To begin with, the tap changers were constructed from diverter switches based on the toggle-lever principle (see picture) and separate selectors. With the type C, however, Maschinenfabrik Reinhausen combined the components in one housing (tube) with a rotating contact system for the first time. This design was more compact and enabled easier maintenance, and meant that the diverter switch was located inside the transformer, protecting it from the weather.

Approx. 8,770 units produced / Highest voltage for equipment: 30 kV, then extended to 66 kV

1938 First on-load tap-changer with separate diverter switch and selector

1938 First on-load tap-changer with separate diverter switch and selector

Even before the Second World War, Maschinenfabrik Reinhausen was already producing the type C on a small scale as well as coming up with more and more innovations. At the end of the 1930s, the Scheubeck brothers produced the first prototypes of the type D as an on-load tap-changer with a separate diverter switch and selector. This model went into small-scale production in 1943. It already featured a rotating contact system as well.

Over 13,340 tap changers produced / Highest voltage for equipment: 230 kV

1973 First series production for the global market

1973 First series production for the global market

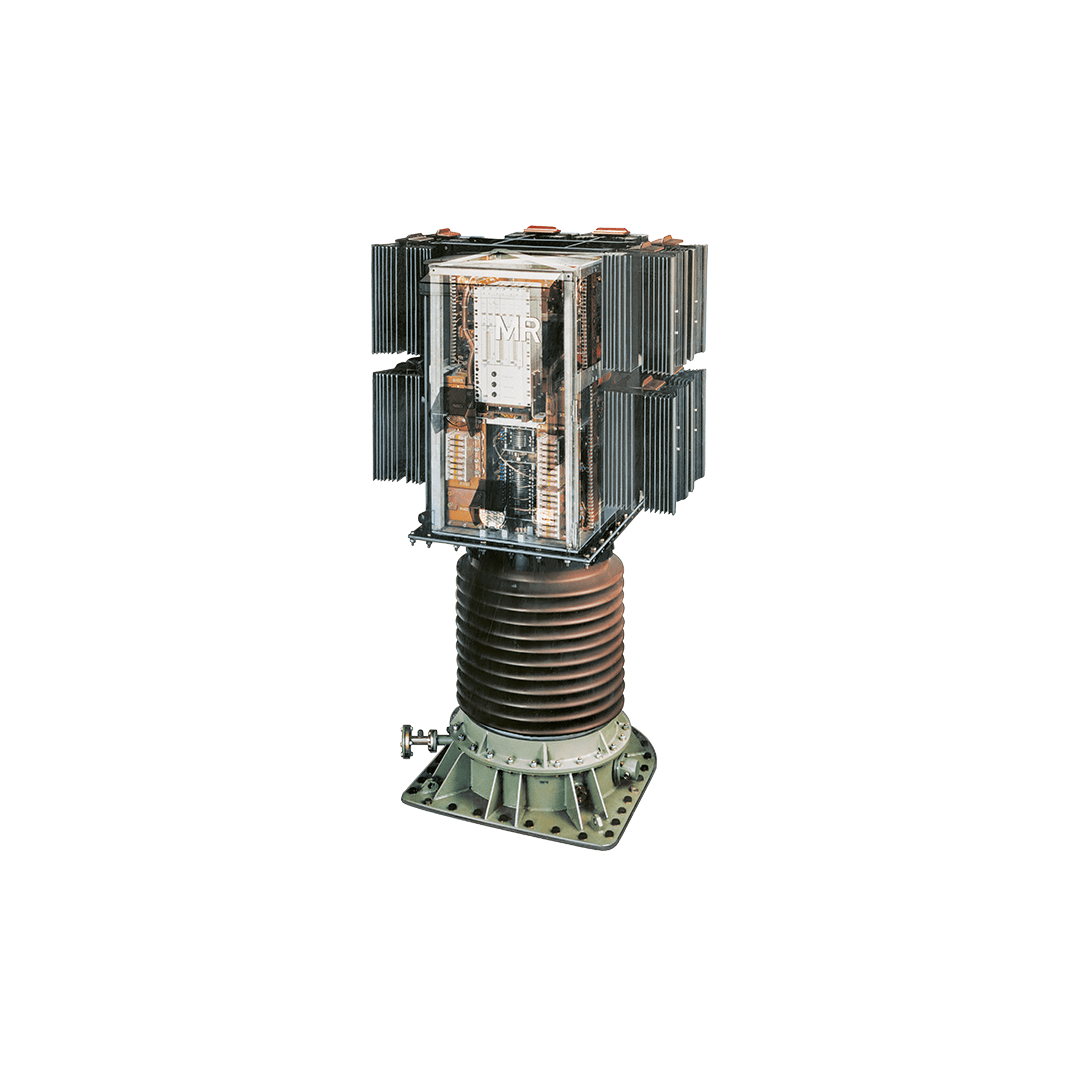

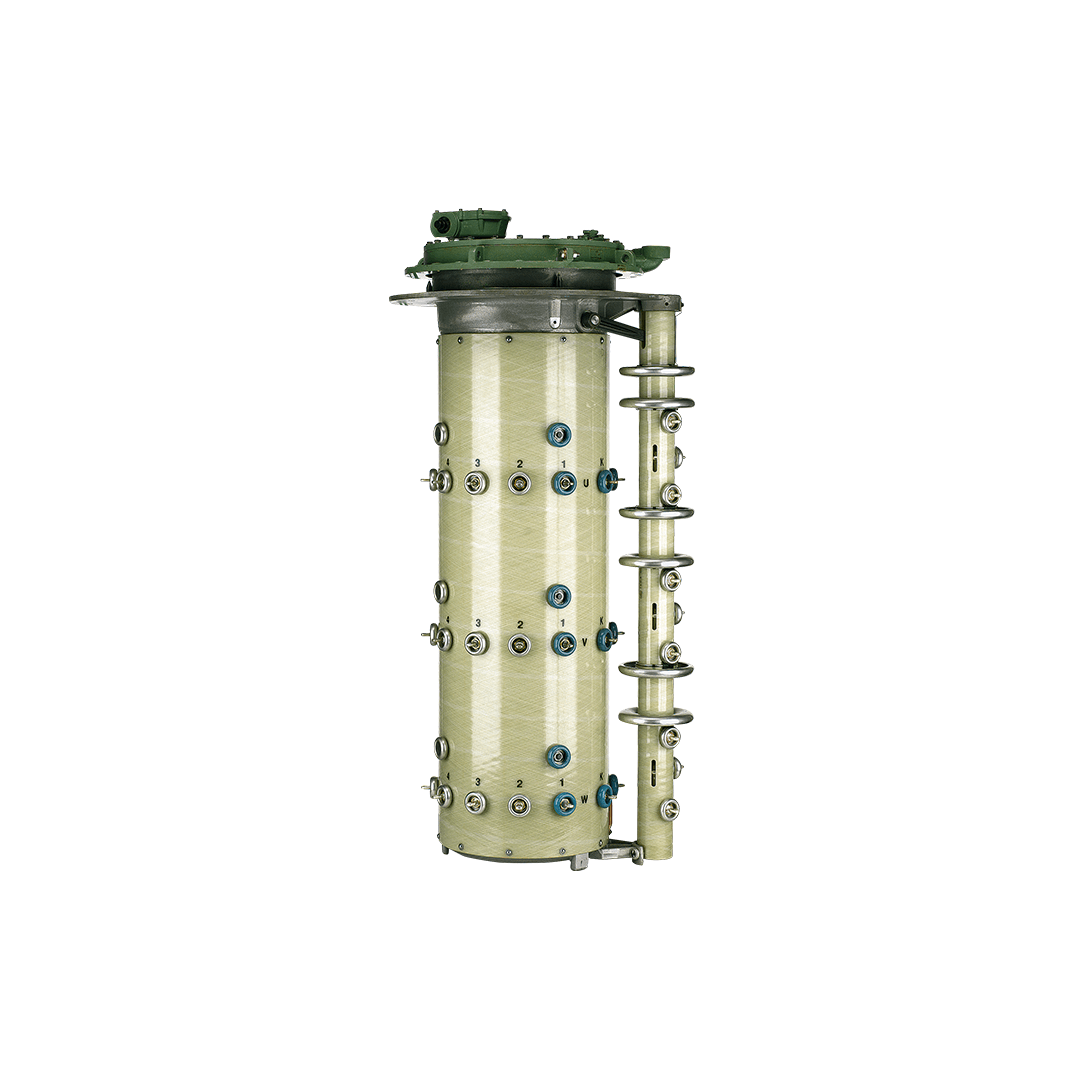

Reinhausen responded to the success of the type D and growing international demand with the OILTAP® M. It featured many machine-produced components, enabling a more compact design and higher production volumes. One of the innovations of the OILTAP® M was its oil compartment: From the end of the 1970s onward, this was made from GRP (glass-reinforced plastic) rather than laminated paper. Reinhausen was the first manufacturer to use this innovative material for its on-load tap-changer.

Over 65,000 units in use worldwide / Highest voltage for equipment: 300 kV / Field of application: Transformers with medium output rates, large power transformers, process transformers, and special transformers

1974 First semiconductor tap-changer

1974 First semiconductor tap-changer

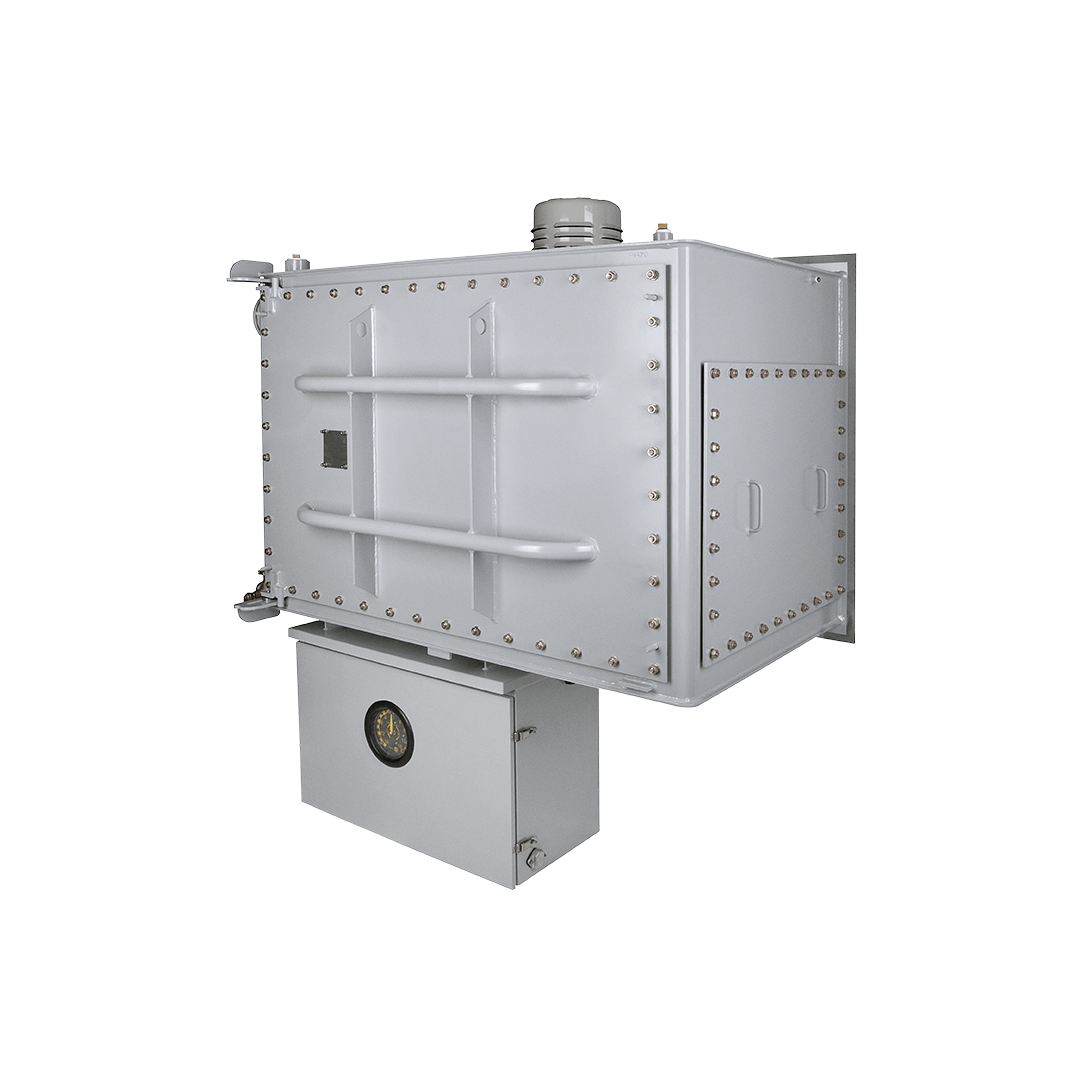

The OILTAP® M may have been maintenance-free up to 50,000 switching operations, but when used in smelters with over 300,000 switching operations per year, that still means maintenance needs to be performed up to six times a year with up to four contact changes. To enable wear-free switching operations, Reinhausen built the first hybrid tap changer with a power electronic diverter switch for the Argentière aluminum smelter in France in 1974. For this tap changer, also known as the “black giant”, the temperature-sensitive semiconductor technology was located outside the transformer.

Quantity produced: Seven units in total / Special feature: Maintenance-free up to 1,000,000 switching operations

1990 First reactor-type tap-changer

1990 First reactor-type tap-changer

At the end of the 1980s, Reinhausen took over the reactor-type tap-changer division of Westinghouse Electric Corporation. Reinhausen made a few technical modifications and launched its first reactor-type tap-changer on the US market in 1990. The VACUTAP® RMV was not only the first tap changer for Reinhausen with a reactor as transition impedance, but also marked the company’s first steps into the world of vacuum switching technology.

Over 12,000 units in use worldwide / Maintenance free up to 500,000 switching operations / Special feature: Internal oil heating system for Arctic use

1995 First vacuum tap changer for dry-type transformers

1995 First vacuum tap changer for dry-type transformers

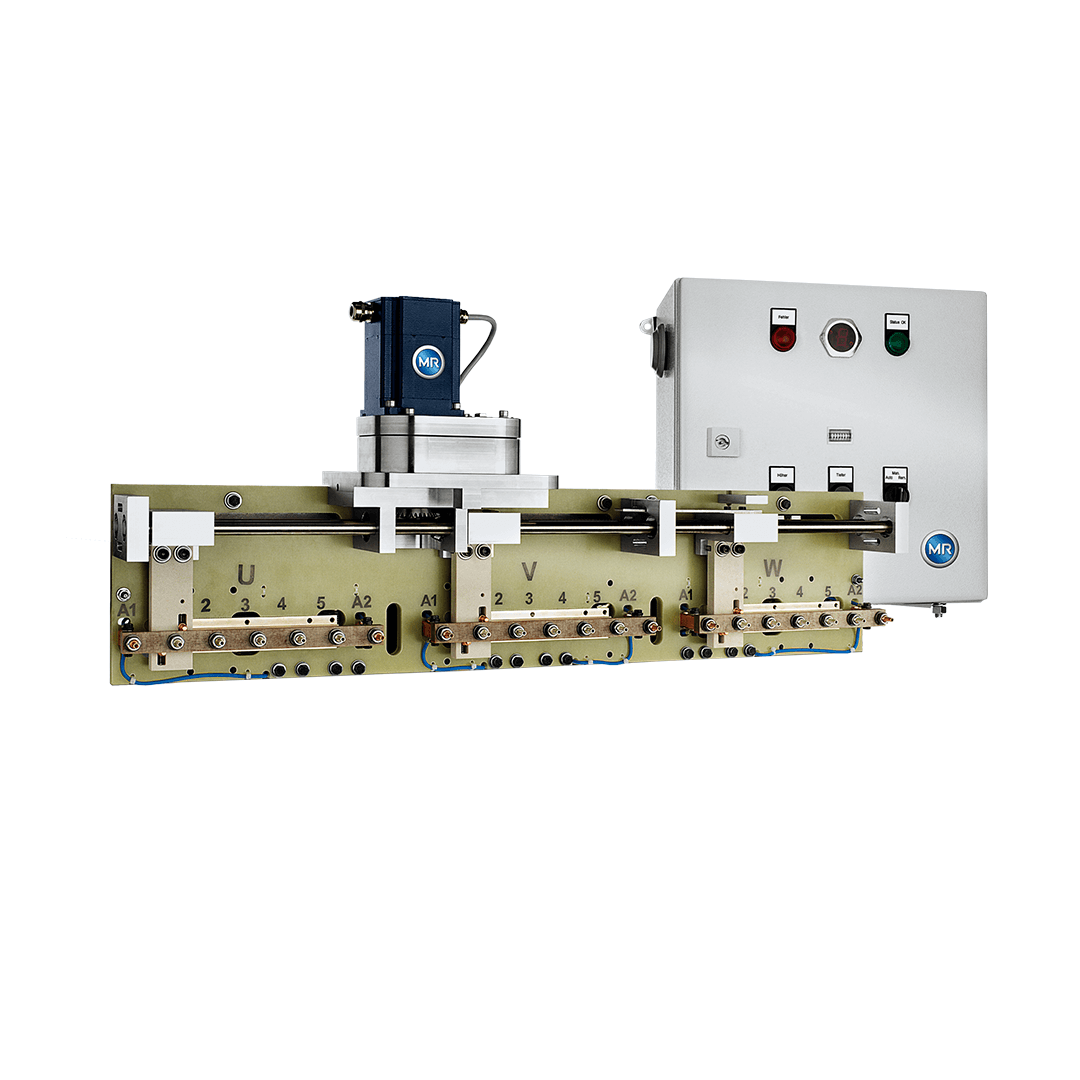

Dry or cast-resin transformers are used in situations where oil is prohibited for fire-safety or nature-conservation reasons. With the VACUTAP® VT®, Reinhausen launched one of the world’s first high-speed resistor-type tap-changers with vacuum-switching technology for dry-type transformers. Thanks to the success of this product, the use of vacuum-switching technology with this type of tap changer gained more acceptance.

Mechanical service life up to 800,000 switching operations / Selector with spring energy accumulator / Easy connection by assigning one tap-changer module to each transformer limb

2000 First resistor-type tap-changer with vacuum technology for oil-filled transformers

2000 First resistor-type tap-changer with vacuum technology for oil-filled transformers

With vacuum-switching technology, there is no arcing in the tap-changer oil, which results in less contamination and maximizes the service life. These advantages convinced Reinhausen to move into vacuum-switching technology for high-speed resistor-type tap-changers as well. With the launch of the VACUTAP® VV® in 2000, Reinhausen was the first manufacturer to bring vacuum-switching technology to series production for installation inside oil-filled transformers. The diverter switch and selector are integrated in an oil compartment. For the first time, this meant zero maintenance for virtually all network applications.

Over 12,000 units in use worldwide / Maintenance-free up to 300,000 switching operations / Minimal operating costs

2012 First series solution for local grid regulation transformers

2012 First series solution for local grid regulation transformers

As more and more small-scale producers of renewable energy started to feed into the grid, it became more important to be able to regulate the Distribution networks as well. The GRIDCON® iTAP®, launched by Reinhausen in 2012, was the first series solution for voltage regulation distribution transformers (VRDT). The system comprises an on-load tap-changer, motor-drive unit, and voltage regulator. The GRIDCON® iTAP® also features vacuum-switching technology and is therefore maintenance-free over its entire life cycle.

Maximum number of tap-change operations: 700,000 / Can be used at any point in the winding

2014 First full semiconductor tap-changer

2014 First full semiconductor tap-changer

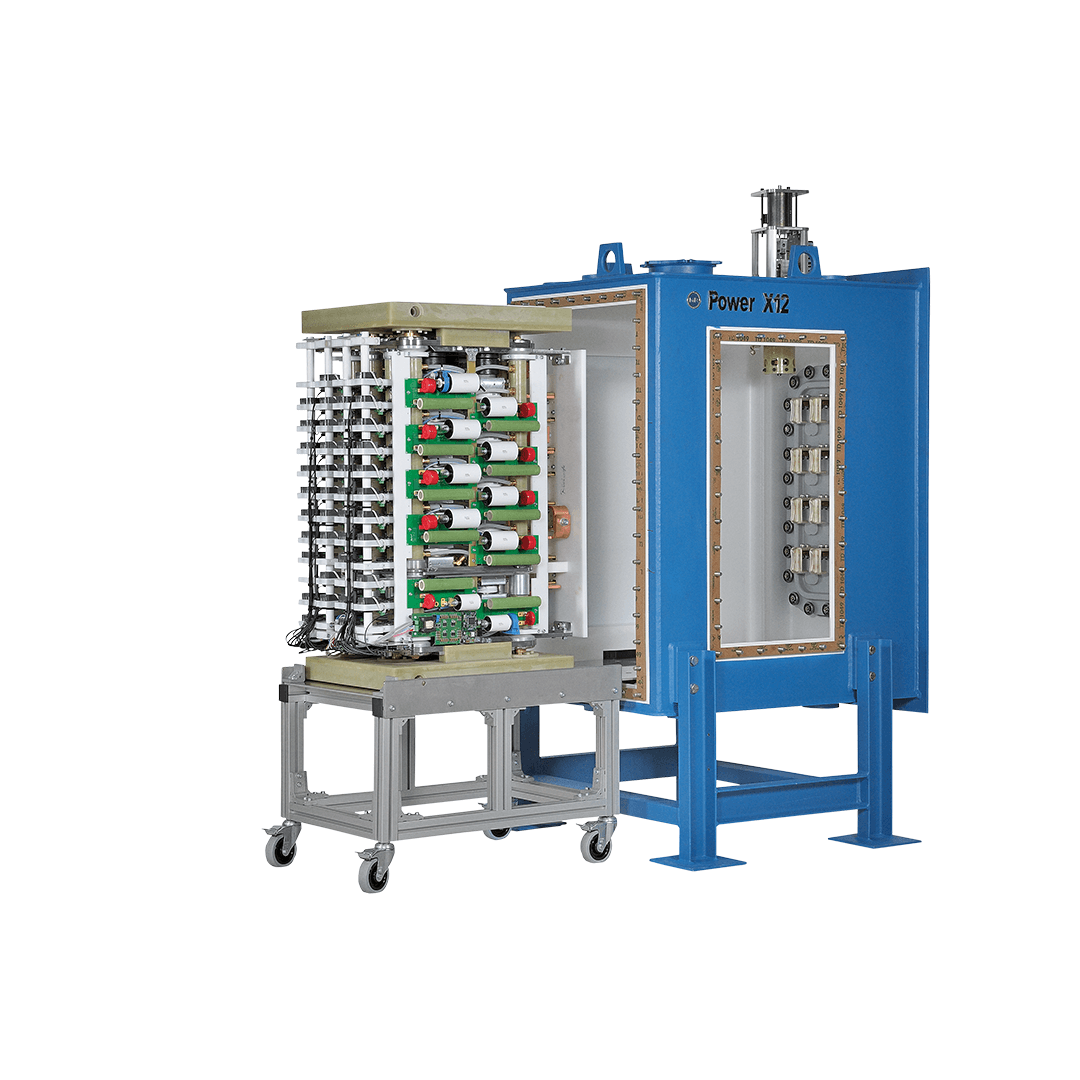

The Power X12 is the first tap changer for electric arc furnace transformers which is based entirely on semiconductor technology.

The system was not put into production for financial reasons. If, in the future, it becomes possible to produce semiconductor tap changers at a reasonable cost, Reinhausen already has the necessary expertise.

2015 First top drive with integrated monitoring

2015 First top drive with integrated monitoring

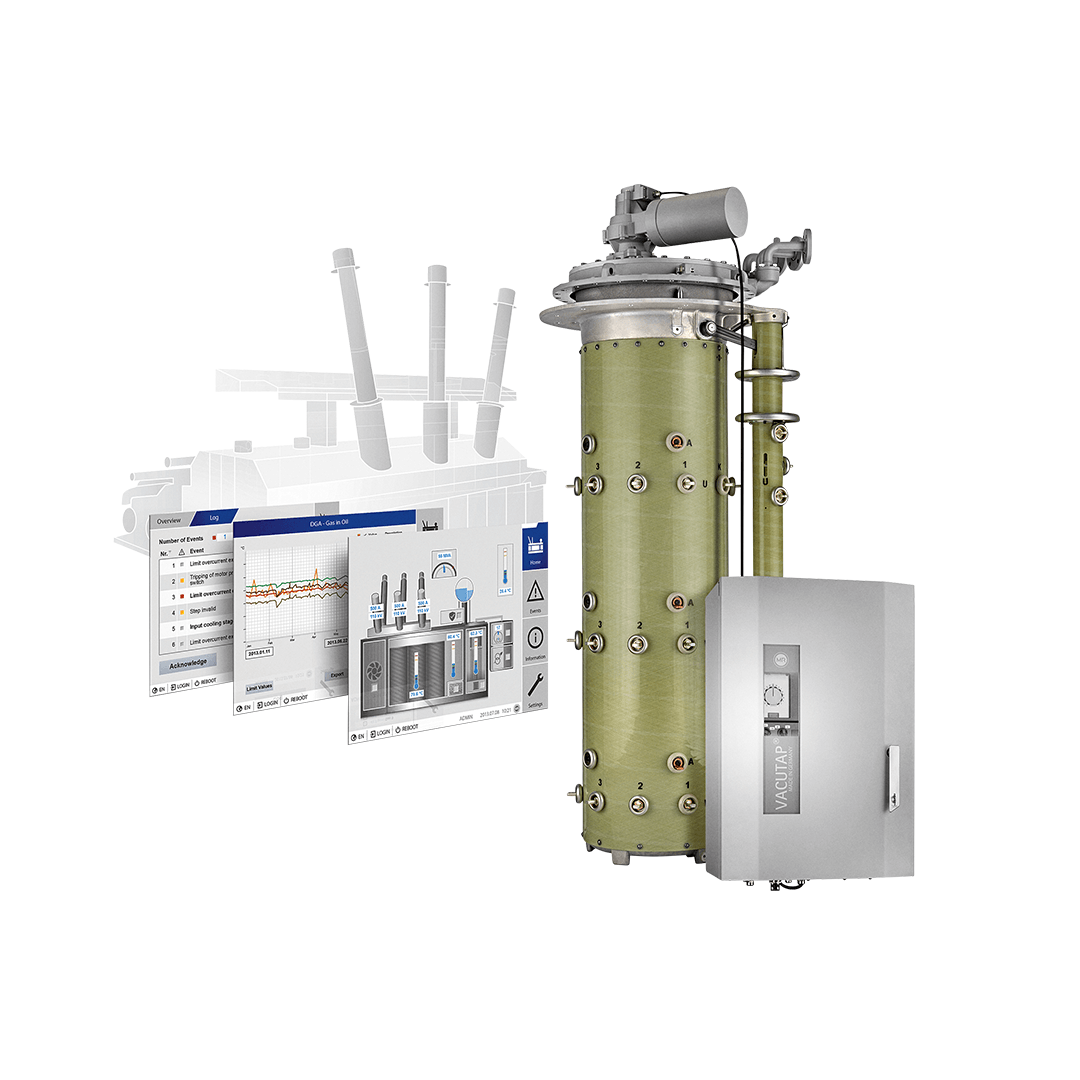

With the TAPMOTION® TD ISM®, Reinhausen placed the motor-drive unit directly on the tap-changer cover for the first time. The drive commands are transmitted from a control cabinet via a cable connection. The ISM®(Integrated Smart Module) technology provides the platform for recording and evaluating all of the transformer’s operating data.

The control cabinet and cable connection provide the basis for a multitude of control and monitoring functions, thus paving the way for the digitalization of the transformer

2016 First tap changer for distribution transformers with electronic control

2016 First tap changer for distribution transformers with electronic control

In 2016 Reinhausen launched the ECOTAP® VPD®, the world’s first high-speed resistor-type tap-changer for distribution transformers with electronic control. Voltage regulation distribution transformers (VRDT) keep the voltage in the distribution network stable. They compensate for fluctuations in the medium voltage and respond dynamically to changes in feed-in and load at the low-voltage level.

Maximum number of tap-change operations: 500,000 / No change to dimensions of transformer (footprint) / Broad application spectrum (utility companies, industry, renewable power generation facilities)

2017

First modular power conversion system with voltage controlled harmonic compensation

2017

First modular power conversion system with voltage controlled harmonic compensation

The GRIDCON® Power Conversion System is a versatile, modular inverter/converter system for DC and AC supply in electrical grids. The PCS can be used to integrate energy storage solutions in low-voltage grids, as well as for other applications. The system supports a wide range of field-tested applications including on-grid and off-grid operation. It can be configured and enhanced based on customer needs. A variety of designs are available for use in the grid or in industrial applications.

Modular design of hardware & software / Seamless transfer from on-grid to off-grid operation / Power quality functions for your battery storage system

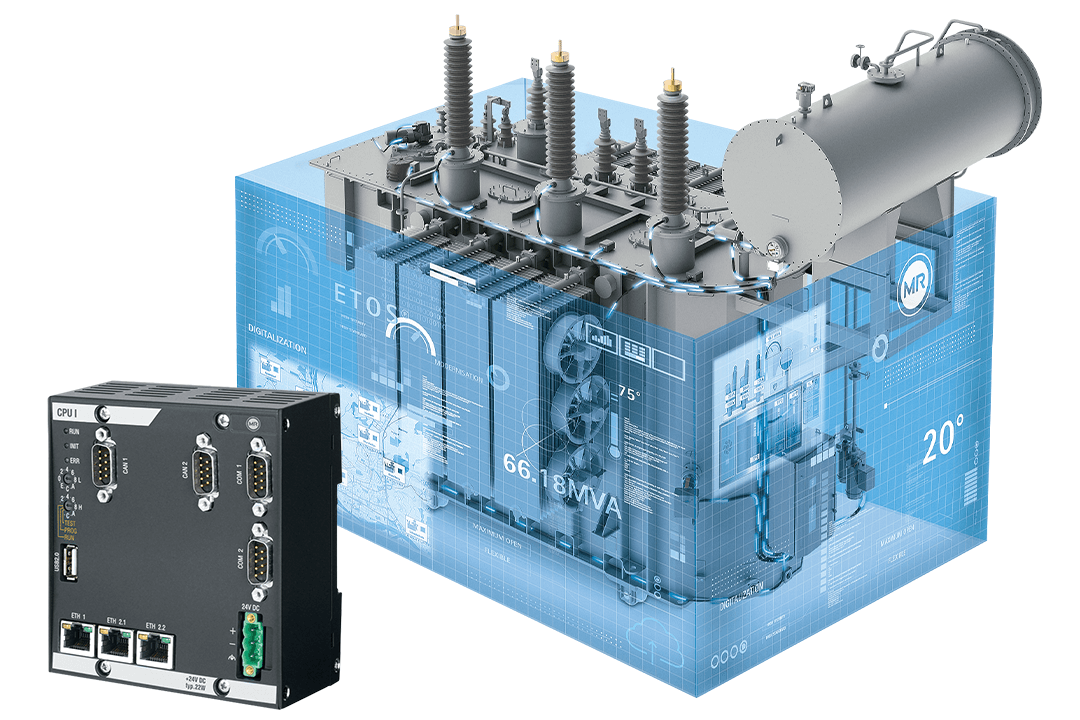

2018 First open operating system, ETOS®, for the digitalization of transformers

2018 First open operating system, ETOS®, for the digitalization of transformers

With ETOS®, Reinhausen is setting new standards in the digitalization of power transformers. The modular solution is the first open, cross-manufacturer operating system for power transformers which connects together all the components and systems of the transformer. The overall concept, comprising sensors, field devices for control, regulation, and monitoring, plus superordinate fleet monitoring, enables the transformer to be controlled and monitored intelligently.

Automated real-time monitoring of all equipment / Modular solution which provides a complete solution for power transformers through function integration / Cross-manufacturer applicability and open to third-party components

2020 First intelligent MSENSE® sensor range in combination with ETOS®

2020 First intelligent MSENSE® sensor range in combination with ETOS®

The service life of a transformer is vitally dependent on the transformer's operating conditions and its environment. It is important to be aware of the weak points in order to prevent damage and disruptions at an early stage. Reinhausen offers the intelligent MSENSE® sensor family and the maintenance-free MTRAB® dehydrating breather in combination with ETOS®, the first open operating system for power transformers, as a perfectly customized software and hardware system.

A new dimension of reliability: This intelligent system helps to optimize and protect the entire service life of the transformer.

2021

First isolated DC/DC converter that behaves similarly to a regulated power transformer used for AC grid applications

2021

First isolated DC/DC converter that behaves similarly to a regulated power transformer used for AC grid applications

The GRIDCON® DC transformer meets the high safety requirements for local DC grids thanks to its galvanic isolation. Its high efficiency and the possibility of controllable bidirectional power transmission enable it to be used in different DC power applications. Uniquely innovative is the combination of these properties with the functional extensions, which among other things enable the operating mode of a controlled transformer for DC grids. Analogous to the conventional AC world, DC grids of different voltages and even different grid configurations can now be connected.

Galvanically isolated DC-DC converter for bidirectional operation / Modular system with 75 kW units / Flexible use for DC voltages between 200 V and 1500 V