Grid operators are in the midst of a turning point: On the one hand, they want to get necessary modernizations in technology and infrastructure underway but, on the other hand, networks must remain stable at all times. Transformer manufacturers can help them in this and become the optimal solution provider for structural change - in the form of a digitalization partnership with Reinhausen, such as the traditional Hungarian company GANZ Transformers and Electric Rotating Machines Ltd. has now concluded.

-

Impulses

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

- Lifetime optimization

- Power supply in industry

- Globalization

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

-

Lifetime optimization

-

Power supply in industry

-

Globalization

Impulses - Portfolio

-

Career

Career

-

Company

Company

Digitalization turnaround: GANZ relies on cooperation with MR

To also ensure grid stability in the future, grid operators can rely on support from their transformer manufacturers.

Digitalization turnaround: GANZ relies on cooperation with MR

To also ensure grid stability in the future, grid operators can rely on support from their transformer manufacturers.

Cooperation creates the future

Asset management tasks will become increasingly complex and difficult to perform in the future. This makes condition-based monitoring and maintenance as well as central control of intelligent transformers necessary. MR supports transformer manufacturers in equipping their customers quickly and efficiently. The core of this partnership is the ISM® platform, in which all applications and functions are integrated. OEMs configure these according to the needs of their customers and receive an individually assembled product from MR - including corresponding OEM branding.

„The collaboration with Reinhausen enables us to bring new products to the market that our clients need in this age of digitalization and climate change.“

Jan Prins, CEO of GANZ Transformers

Central evaluation of all assets

All the data from the entire sensor system converge in the intelligent control cabinet and are evaluated in the ISM® computing unit. This allows asset managers to seamlessly monitor their fleet and evaluate it based on its condition. MR helps OEMs assemble the desired components independently of the manufacturer and assembles the systems in Regensburg. Transformer manufacturers merely connect them. In addition, they are enabled to develop their own software such as special algorithms and thus their own business models on the basis of ISM®. MR thus provides OEMs with tools to actively shape digitalization and, in the process, to reposition themselves in the market. Jürgen Ach, Director of Automation at Reinhausen, relies on cooperation with transformer manufacturers to make production scalable and thus affordable for all OEMs.

„What we are doing here is meaningful, because we are actively enabling the energy transition in an enormously fast developing time.“

Jürgen Ach, Director Automation MR

First cooperation successful

Together with the OEM GANZ Transformers and Electric Rotating Machines Ltd. from Hungary, the new MR project has officially started. Together, the professionals developed GANZ Intelligent Solutions: a solution perfectly tailored to the requirements of GANZ customers. Together, they are thus laying the foundation for establishing the Hungarian OEM as a digital solution provider in the market. In the future, a dedicated customer portal will also enable GANZ and other OEMs to configure their solutions together with customers in real time, including the direct generation of offers as well as individual wiring diagrams.

Partnership for the future:

Jan Prins (right), CEO of GANZ Transformers, and Jürgen Ach, Director Automation MR, seal the collaboration.

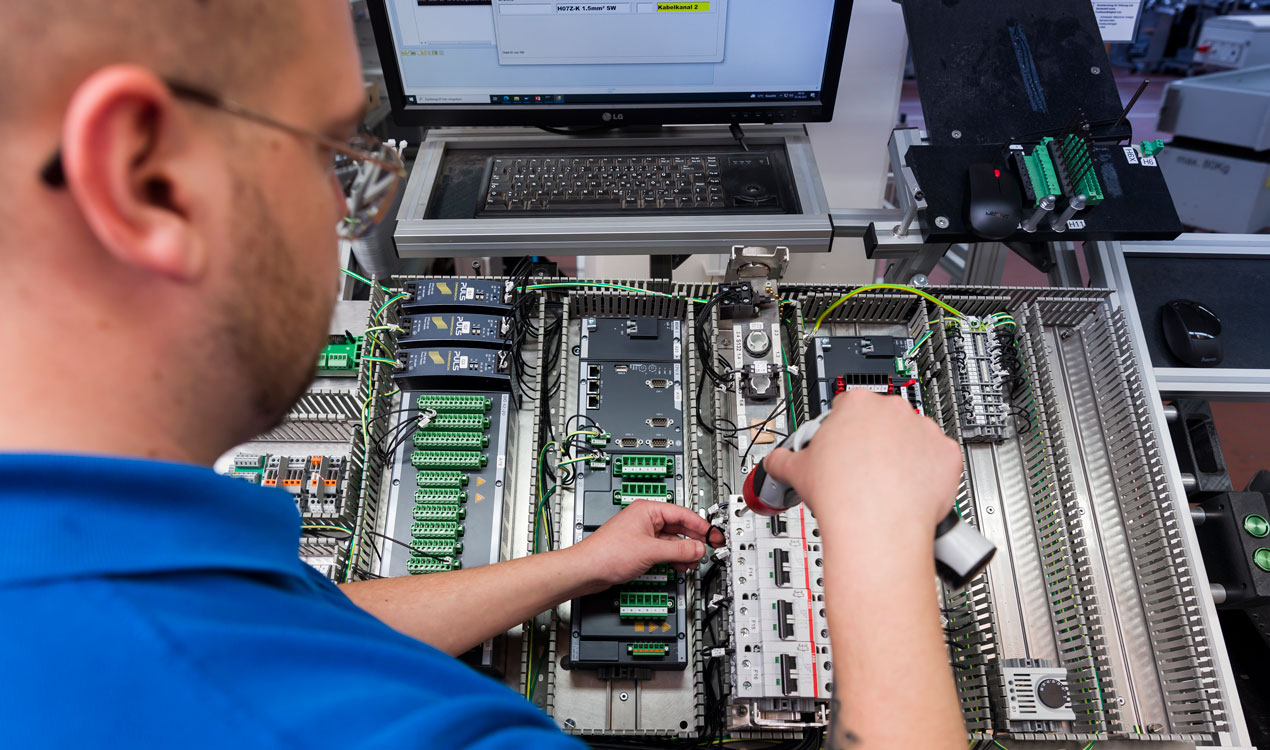

The "brain" of the system:

The ISM® modules are pre-assembled and form the intelligent data center of the unit.

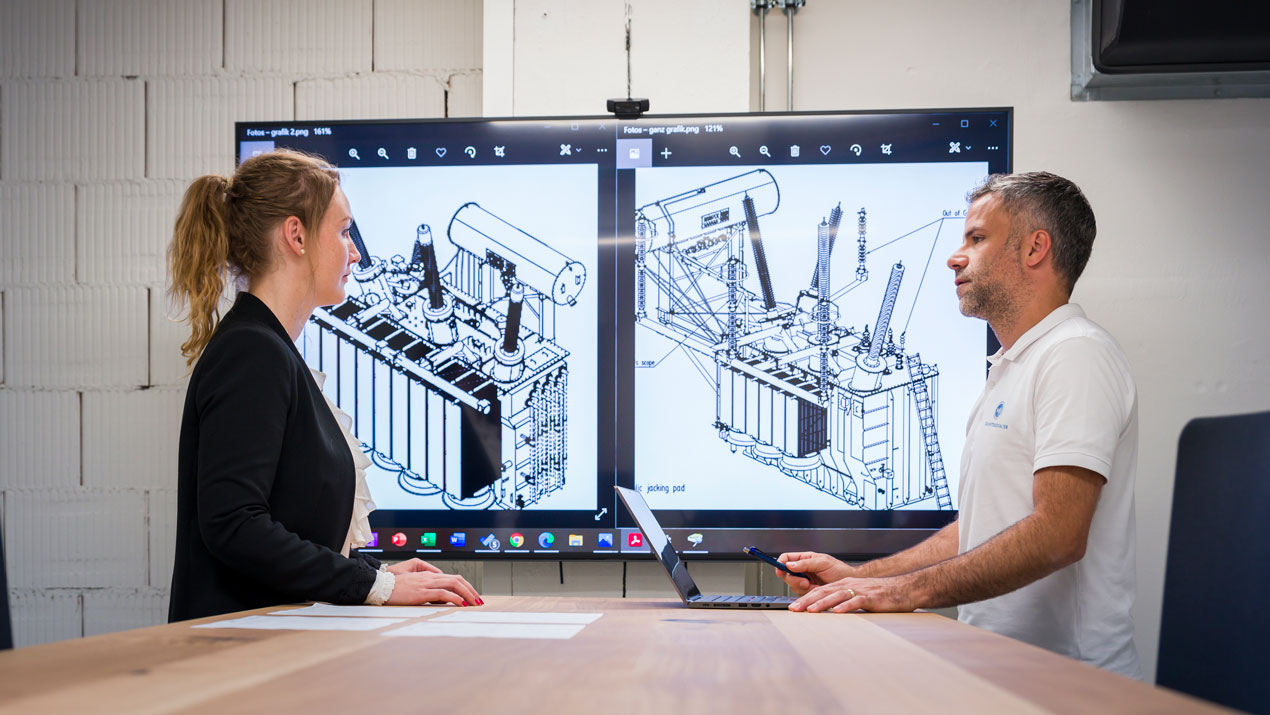

Individually planned:

With the support of Oktay Akkas, Business Development Manager at Reinhausen, GANZ develops customer packages perfectly tailored to its needs.

Sebastian Hilmer, Reinhausen Head of OEM Cooperations:

We offer an extensive cooperation program to support OEMs on their way to becoming solution providers.

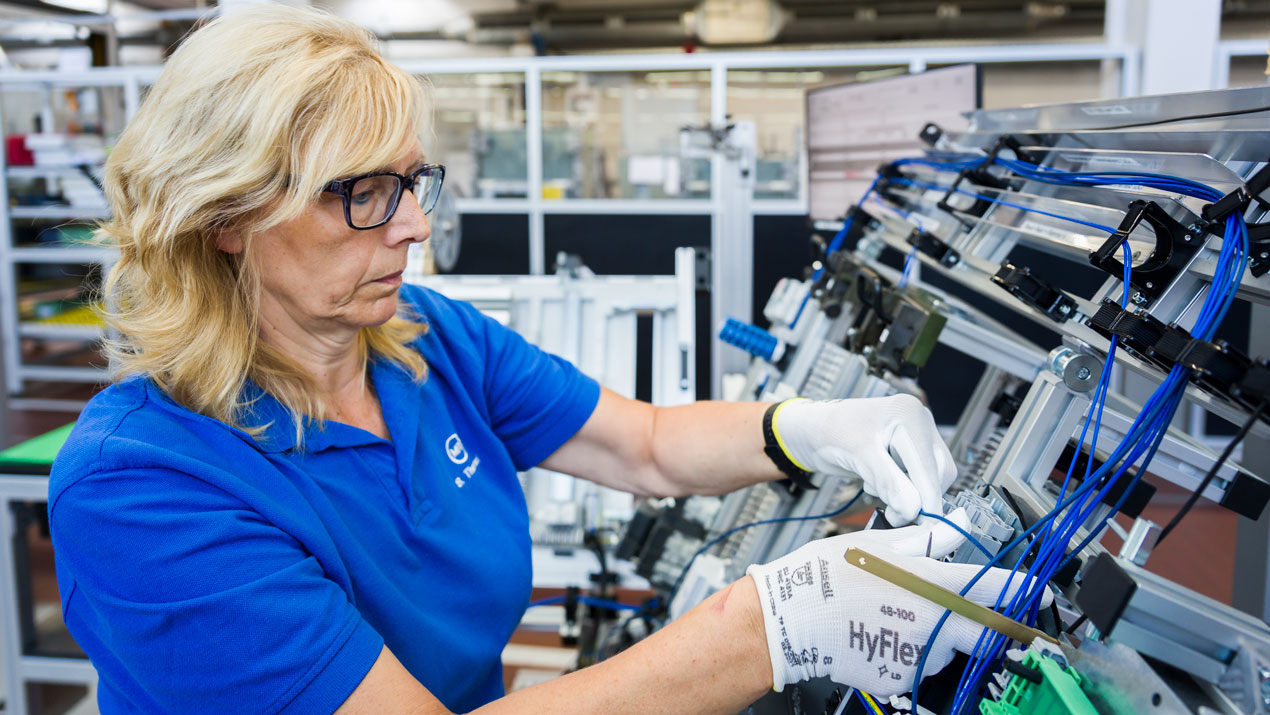

Production in Regensburg:

OEM solutions are made on the production line, entirely based on customers' individual requirements, and fully assembled.

Detailed preparation:

GANZ and MR specialists devise engineering circuit diagrams together. In this way, all the information is compiled in a central location

Herbert Schubert, Reinhausen Area Sales Engineer:

"Together with GANZ Transformers, we are pursuing our shared vision of a standardized solution for automation and digitalization at the node, the transformer."

Ready to go:

Precise and fast wiring of all components is already completed at Reinhausen. This saves customers valuable time.

Final check before delivery:

On the IEC test bench, specialists test in accordance with the NORM whether the unit is working perfectly and as ordered.

Gábor Farkas, Strategic Purchaser at GANZ Transformers:

"Our strategic goal is to combine Reinhausen's digitalization concept with GANZ's comprehensive technical knowledge to create an outstanding system for the benefit of our customers."

Uncomplicated and fast:

With the help of engineering plans, the trained specialists at GANZ can quickly connect the system to their transformer in just a few steps.

Energy transition thanks to digitalization:

Learn more about the ISM® platform and the new cooperation.

News article about digitalization turnaround

We are here for you. Wherever you are.

Looking for the right contact partner?

Do you have a concern, but don't know whom you should contact? You will find that information in our contact overview. In the event of any technical disturbances, our 24/7 support is always at your disposal.

Welcome to myReinhausen

myReinhausen is MR's central, digital customer platform. On myReinhausen, customers can access customer-specific MR information as well as numerous free features related to the MR portfolio.

myReinhausenJoin Reinhausen family

Find your ideal job quickly!

Check our vacancies here. Apply today and contribute at the world market leader in energy technology keeping the energy supply stable in the future.