ETOS® TD

Innovative motor-drive solutions

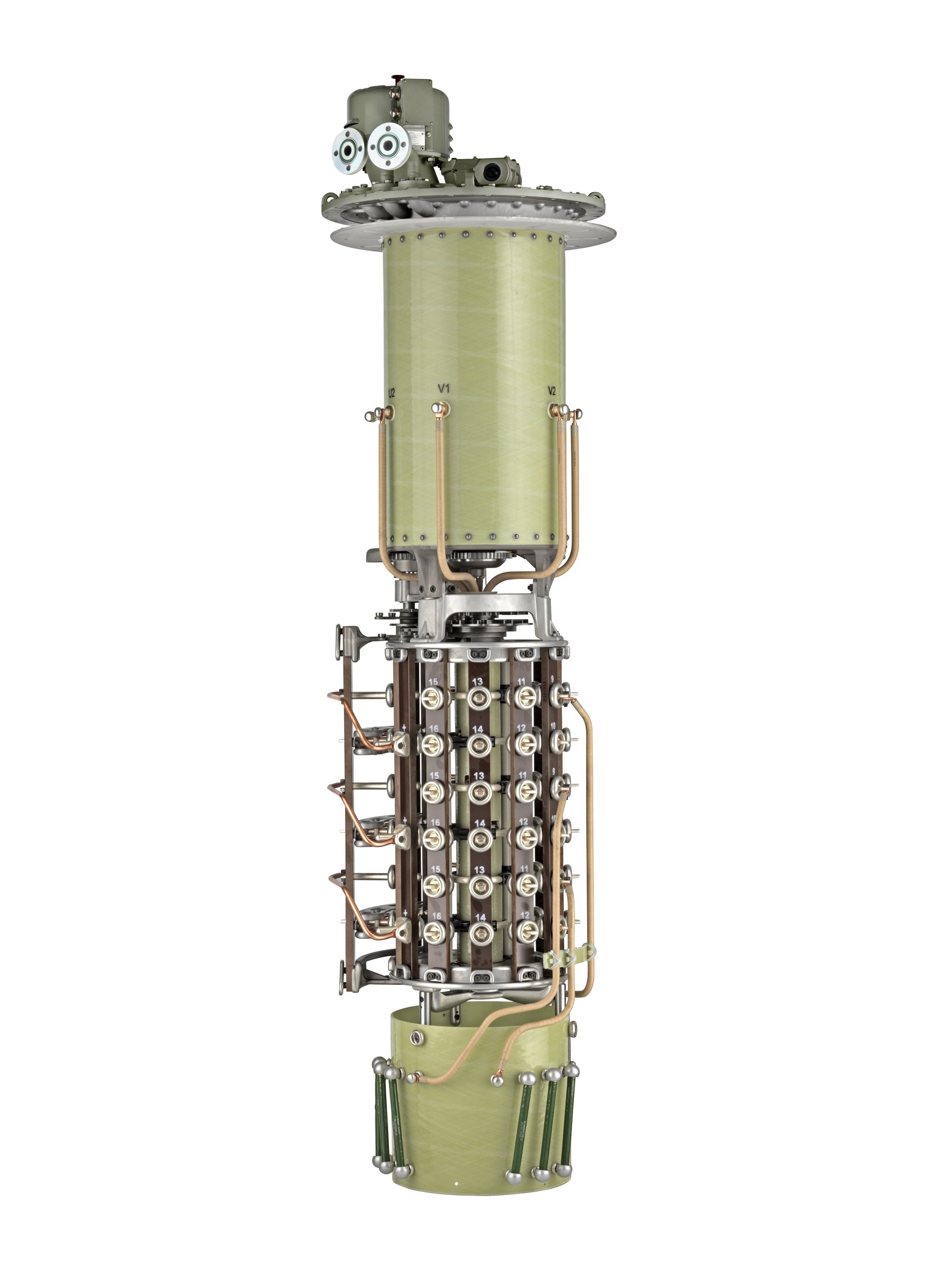

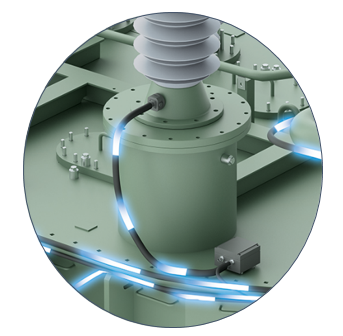

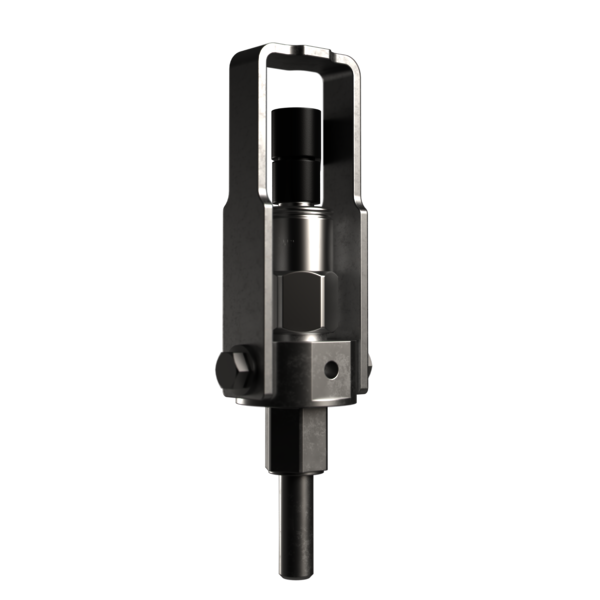

In the ETOS® TD drive for tap changers, the energy is made available precisely where it is needed – i.e. at the tap-changer cover. The drive commands generated in the control cabinet are transmitted via a cable connection to the motor installed above. This eliminates the need for a rigid drive shaft connection and the complex and time-intensive task of installing it. What's more, the precise motor torque delivered to the driven tap changer guarantees maximum safety when switching loads. This is because the smart drive can check all key parameters using the OLTC PreCheck function.

Keep your individual ETOS® solution up to date

myReinhausen

Your Advantages at a Glance

-

Innovative drive for tap changers

-

Benefits during the manufacture and operation of power transformers

-

Smart monitoring and control as the basis for smart transformers

-

Modular scope of function, individual expansion possible

-

Condition-based maintenance

-

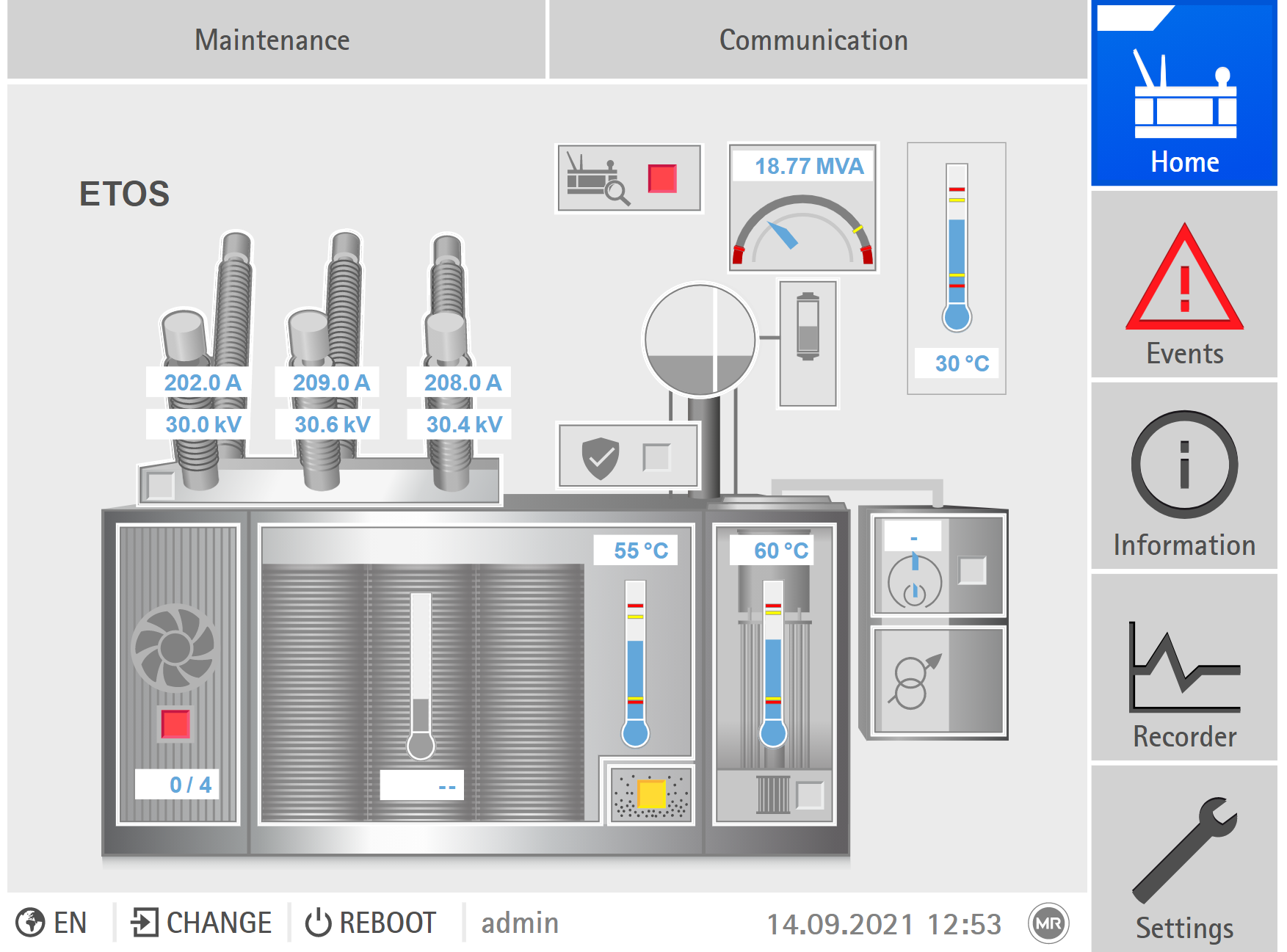

Easy to operate, intuitive graphics interface

Product Information

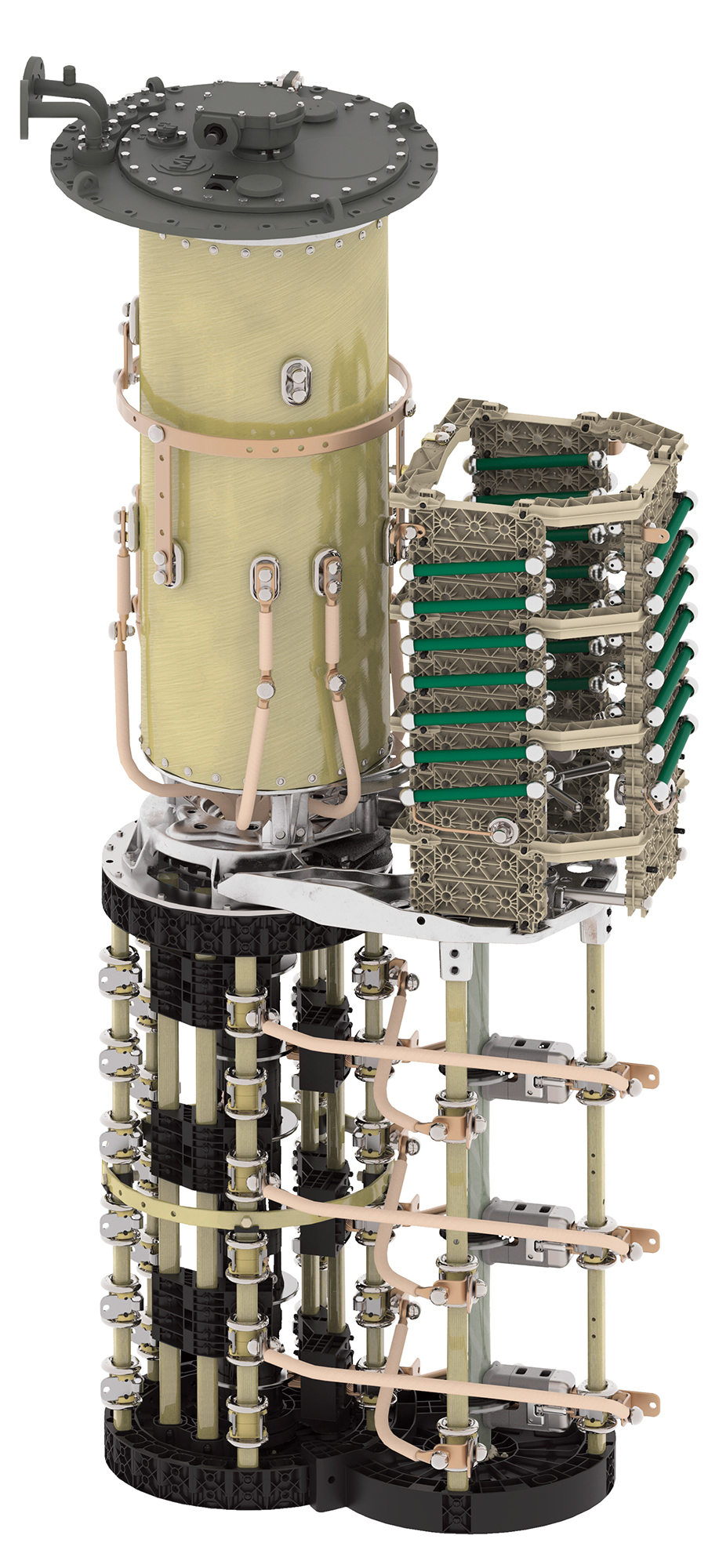

The ETOS® TD is factory-fitted with our very own ISM® technology (Integrated Smart Module). This electronic automation platform is particularly well suited to the special conditions of energy technology. As well as controlling the tap-changer drive, this platform lets you record and evaluate all relevant operating data / sensors from the power transformer. The simple connection of transformer sensors to the control system (SCADA) makes for fast commissioning and even the integrated visualization does not require the installation of any additional software.

This greatly reduces the amount of wiring needed during installation and significantly cuts costs compared to a conventional connection method. This allows you to plan how you operate, service, and replace your equipment in a more efficient and targeted manner. Providing you with intelligent operational management and optimized asset management.

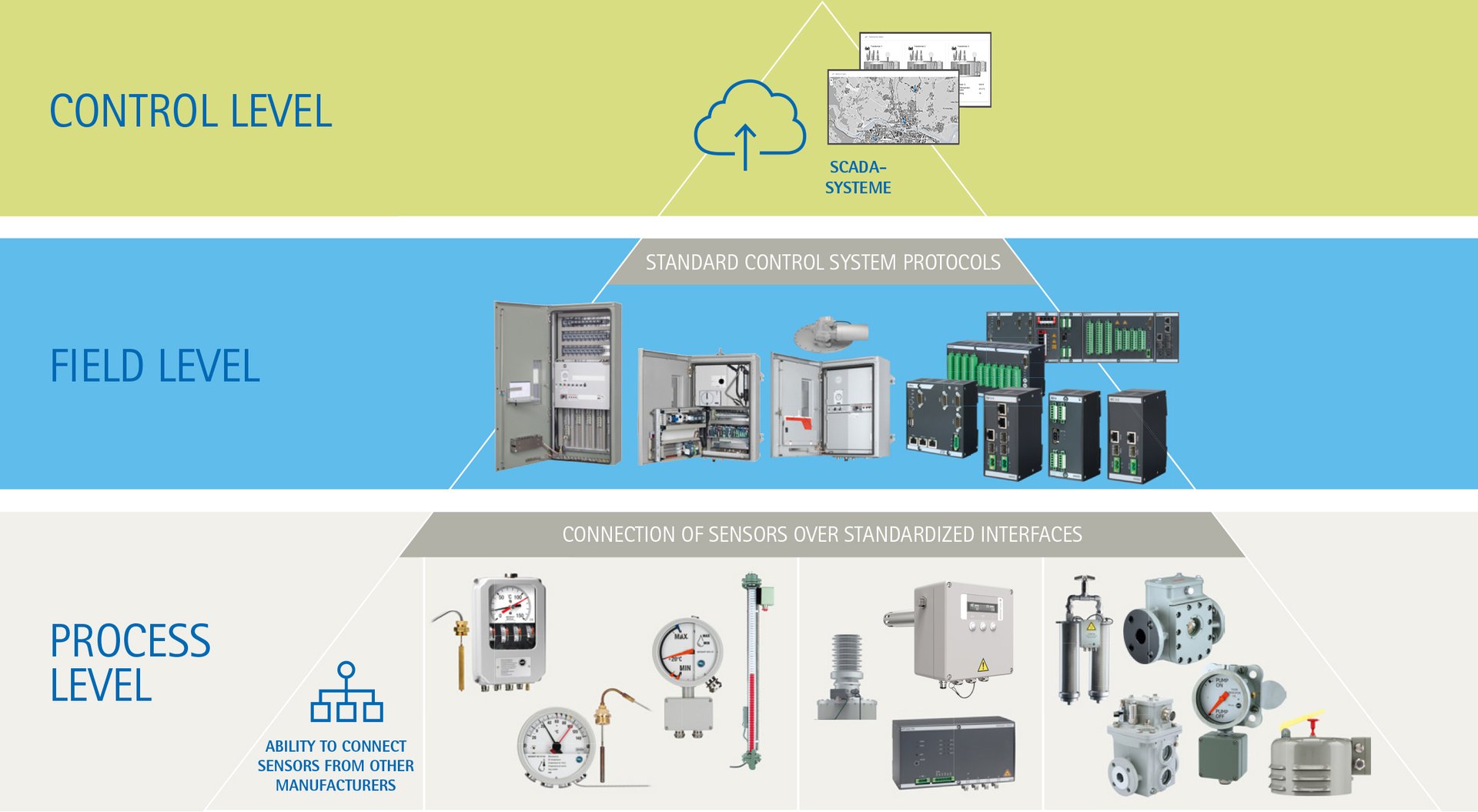

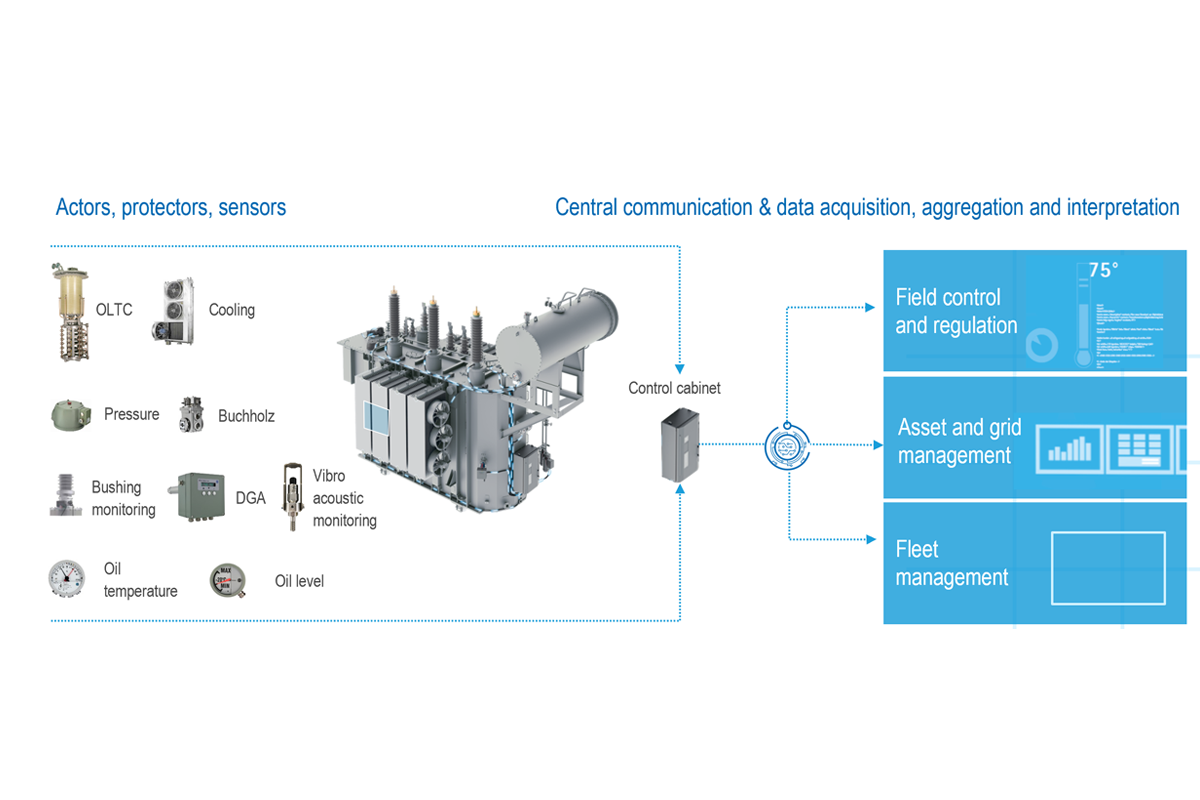

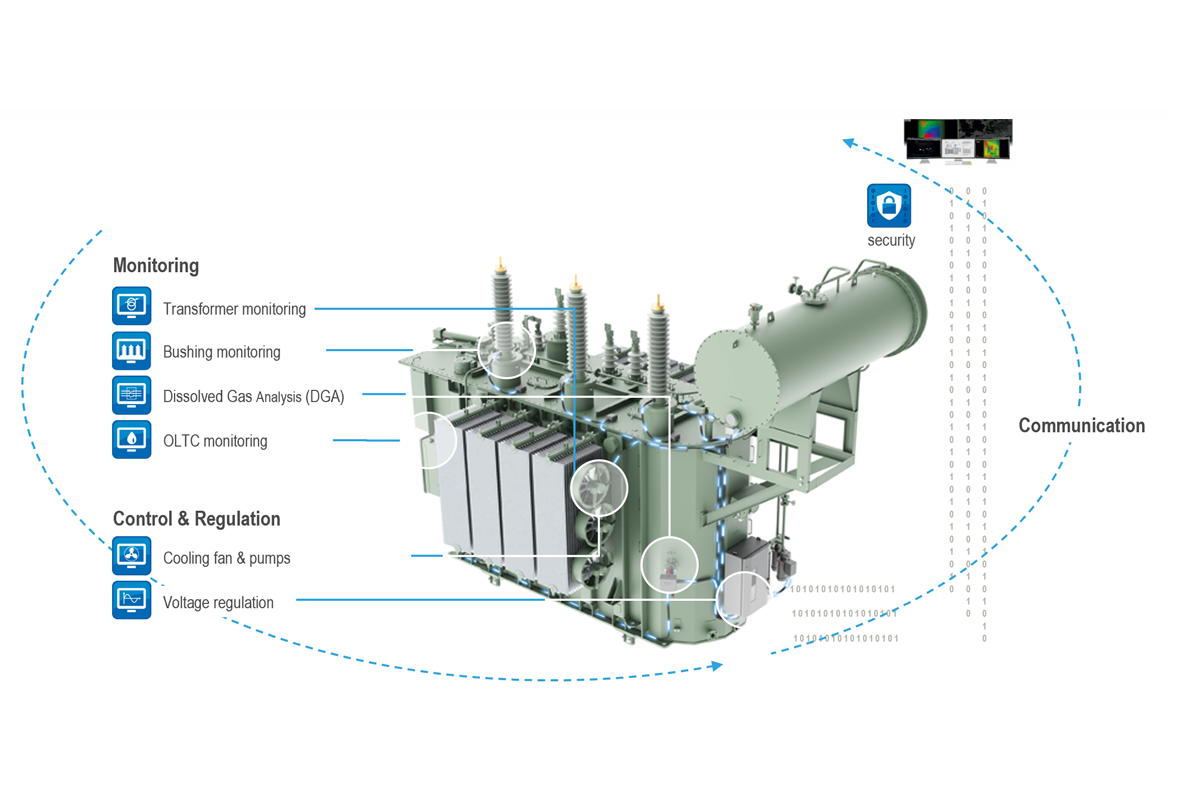

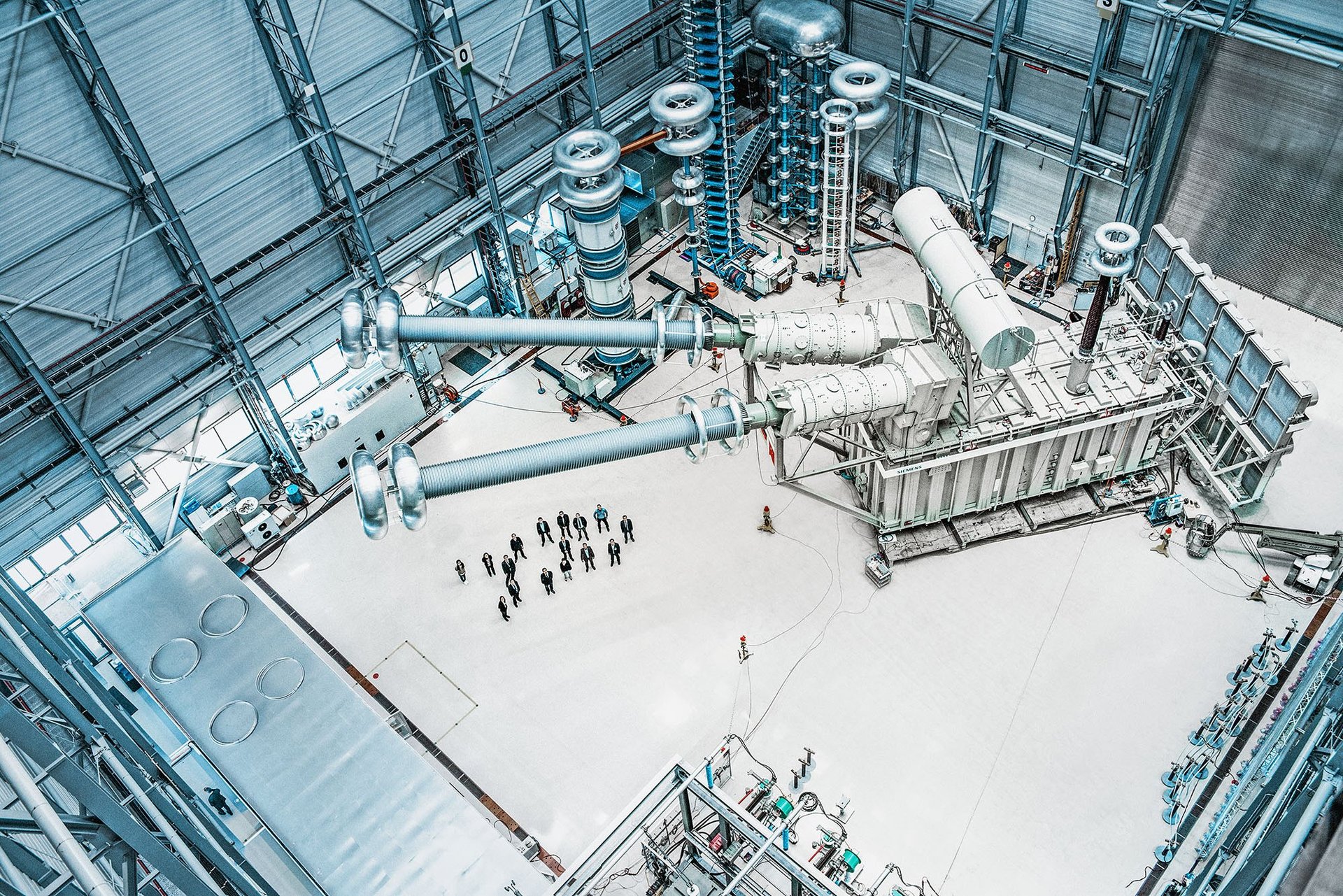

Our system for automating power transformers comprises monitoring and safety equipment, (intelligent) sensors, field devices for control, regulation and monitoring, superordinate fleet monitoring, and all the accessories needed for attachment and communication. We provide solutions for all transformers from all manufacturers, regardless of age and location – for one single transformer or an entire fleet. The subcomponents are split into the process level, field level and control level.

Our solution for automating power transformers is called ETOS® (Embedded Transformer Operating System) and is the world's first open operating system for smart transformers.

Through this approach, we offer a manufacturer-independent system for monitoring, controlling and regulating power transformers. As a complete solution for digitalizing transformers in the field level area, ETOS® forms the interface between the process and the control level. Desired function scopes can be implemented using a modular approach tailored to customer needs – for various transformer types, performance classes and usage areas.

ETOS® can be integrated or retrofitted seamlessly into any environment, on one transformer or an entire fleet. And the best part is that this added value has absolutely no impact on system costs for you.

BENEFITS OF AUTOMATING POWER TRANSFORMERS

- Operating reliability through effective control and prevention of faults

- Cost optimization through condition-based maintenance and functional integration

- Standard of the future in terms of safety and regulatory requirements

Select language

The ETOS® TD is factory-fitted with our very own ISM® technology (Integrated Smart Module). This electronic automation platform is particularly well suited to the special conditions of energy technology. As well as controlling the tap-changer drive, this platform lets you record and evaluate all relevant operating data / sensors from the power transformer. The simple connection of transformer sensors to the control system (SCADA) makes for fast commissioning and even the integrated visualization does not require the installation of any additional software.

This greatly reduces the amount of wiring needed during installation and significantly cuts costs compared to a conventional connection method. This allows you to plan how you operate, service, and replace your equipment in a more efficient and targeted manner. Providing you with intelligent operational management and optimized asset management.

Our system for automating power transformers comprises monitoring and safety equipment, (intelligent) sensors, field devices for control, regulation and monitoring, superordinate fleet monitoring, and all the accessories needed for attachment and communication. We provide solutions for all transformers from all manufacturers, regardless of age and location – for one single transformer or an entire fleet. The subcomponents are split into the process level, field level and control level.

Our solution for automating power transformers is called ETOS® (Embedded Transformer Operating System) and is the world's first open operating system for smart transformers.

Through this approach, we offer a manufacturer-independent system for monitoring, controlling and regulating power transformers. As a complete solution for digitalizing transformers in the field level area, ETOS® forms the interface between the process and the control level. Desired function scopes can be implemented using a modular approach tailored to customer needs – for various transformer types, performance classes and usage areas.

ETOS® can be integrated or retrofitted seamlessly into any environment, on one transformer or an entire fleet. And the best part is that this added value has absolutely no impact on system costs for you.

BENEFITS OF AUTOMATING POWER TRANSFORMERS

- Operating reliability through effective control and prevention of faults

- Cost optimization through condition-based maintenance and functional integration

- Standard of the future in terms of safety and regulatory requirements

Select language

ALL secondary technologies – ONE System

ALL secondary technologies – ONE System

We offer modular system solutions for different applications power rating classes and models of power transformers. Decades of experience in the fields of control and monitoring of power transformers included. Through ETOS® , we are providing a complete open system for automating power transformers for the first time. It comprises monitoring and protective devices, (intelligent) sensors, field devices for control, regulation and monitoring, superordinate fleet monitoring, and all attachment accessories for communication.

The special feature is the simple connection of components in ETOS® . This enables an individualized configuration. Likewise, a simple expansion or renewal of your existing power transformers is possible. In this way, you are able to control and monitor your transformers effectively – for maximum availability and security.

ETOS® function packages

ETOS® function packages

- Drive on-load tap-changer

- Control and monitoring on the transformer

- Central communication interface and data integrator for analog and digital signals and information

- IEC61850, IEC60870-5-101, -103, -104, Modbus, DNP3

- MQTT Publisher optional

- Control cabinet for optimizing your value chain – without raising total costs

- Open for any third-party sensors

- Modular and functionally integrated system solution

Cooperation for OEMs

Cooperation for OEMs

- Cooperation is aimed at all transformer manufacturers (OEMs) who want to profit from the increasing demand for digital transformer solutions

- MR is laying the infrastructure for intelligent transformers with offering the open and neutral ISM® platform as the basis for individual "Digitalized by ISM®" solutions

- Simplifying the transition to intelligent transformers by jointly analyzing and optimizing processes and costs in regard to purchasing, design and engineering