MESSKO® COMPACT

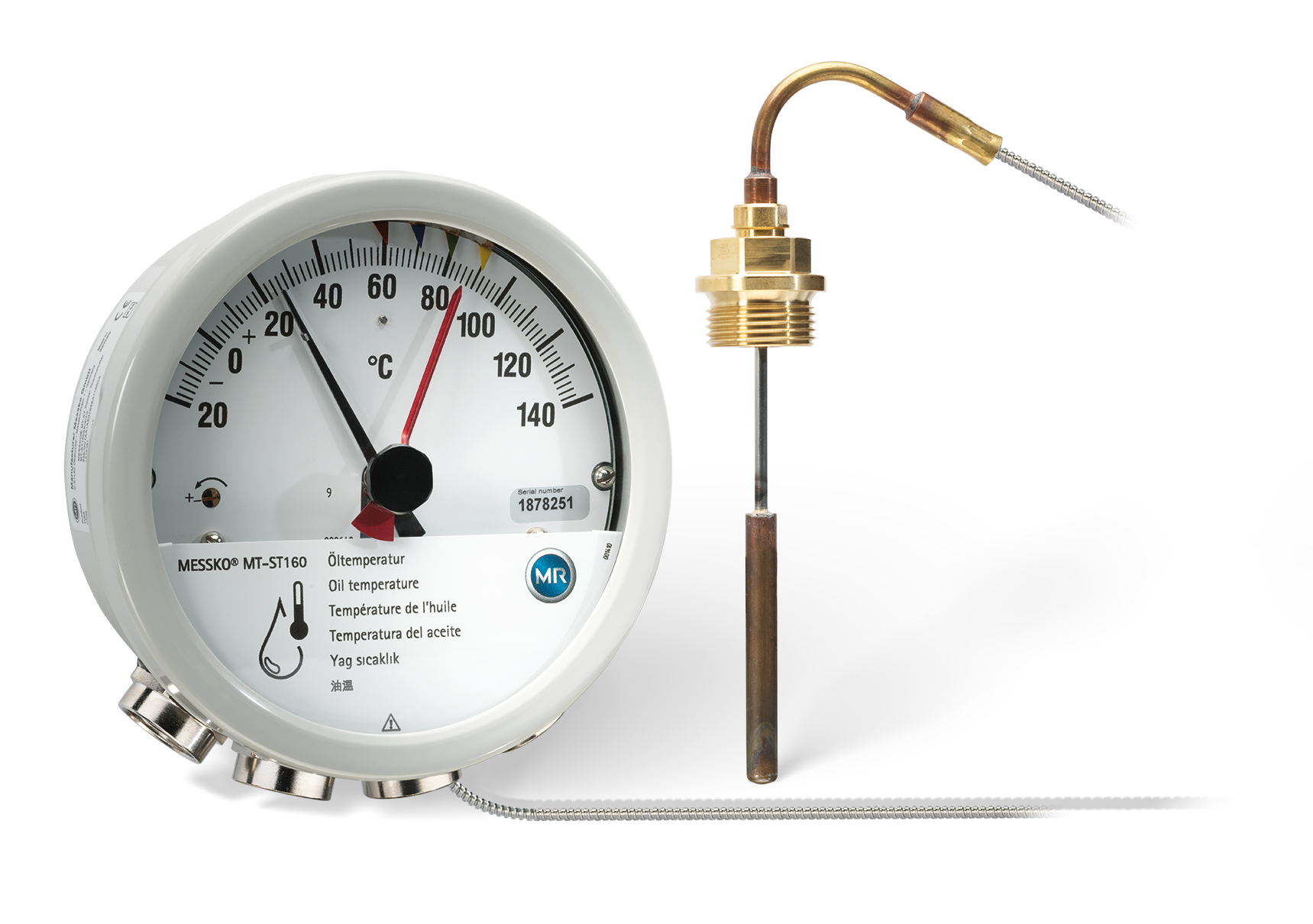

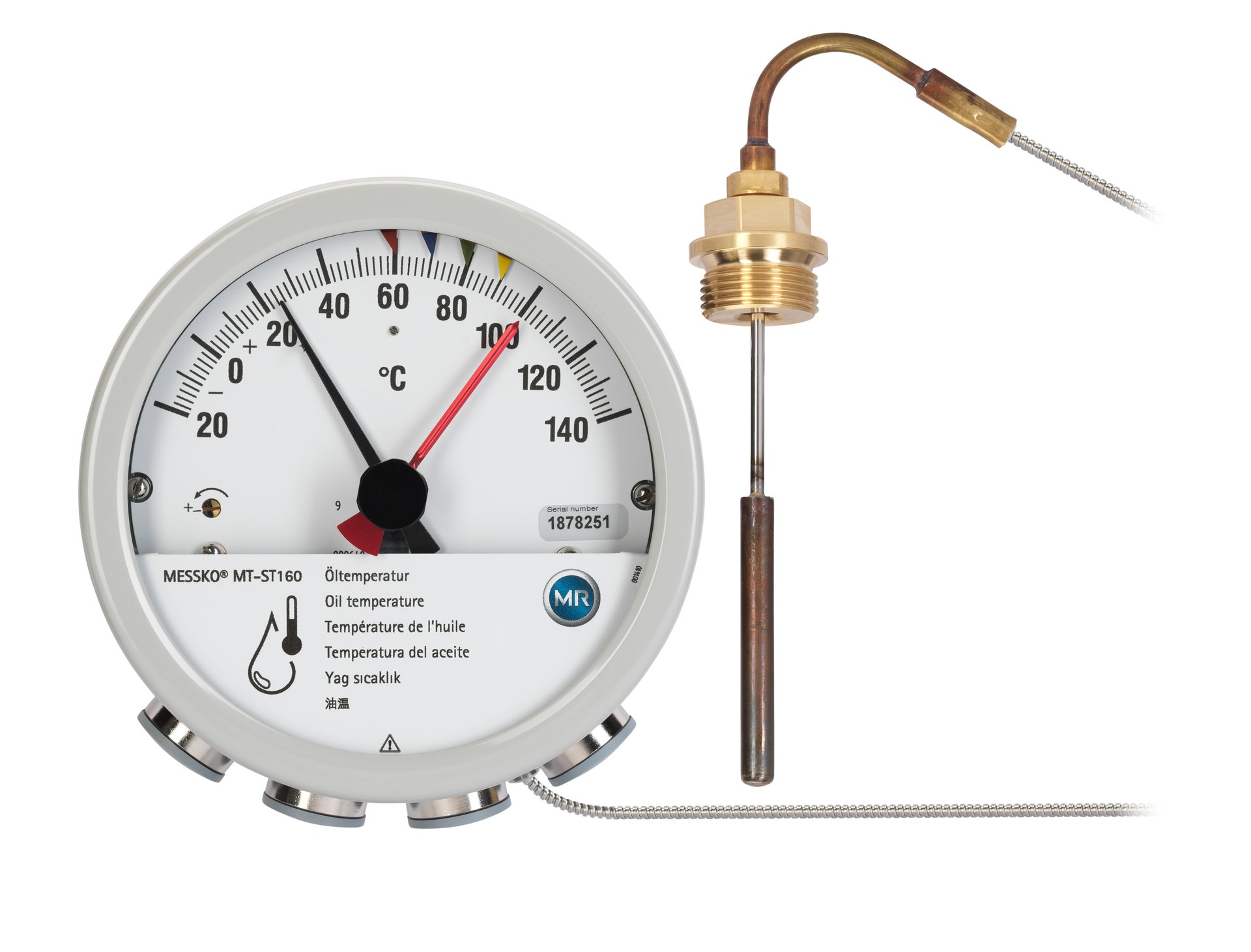

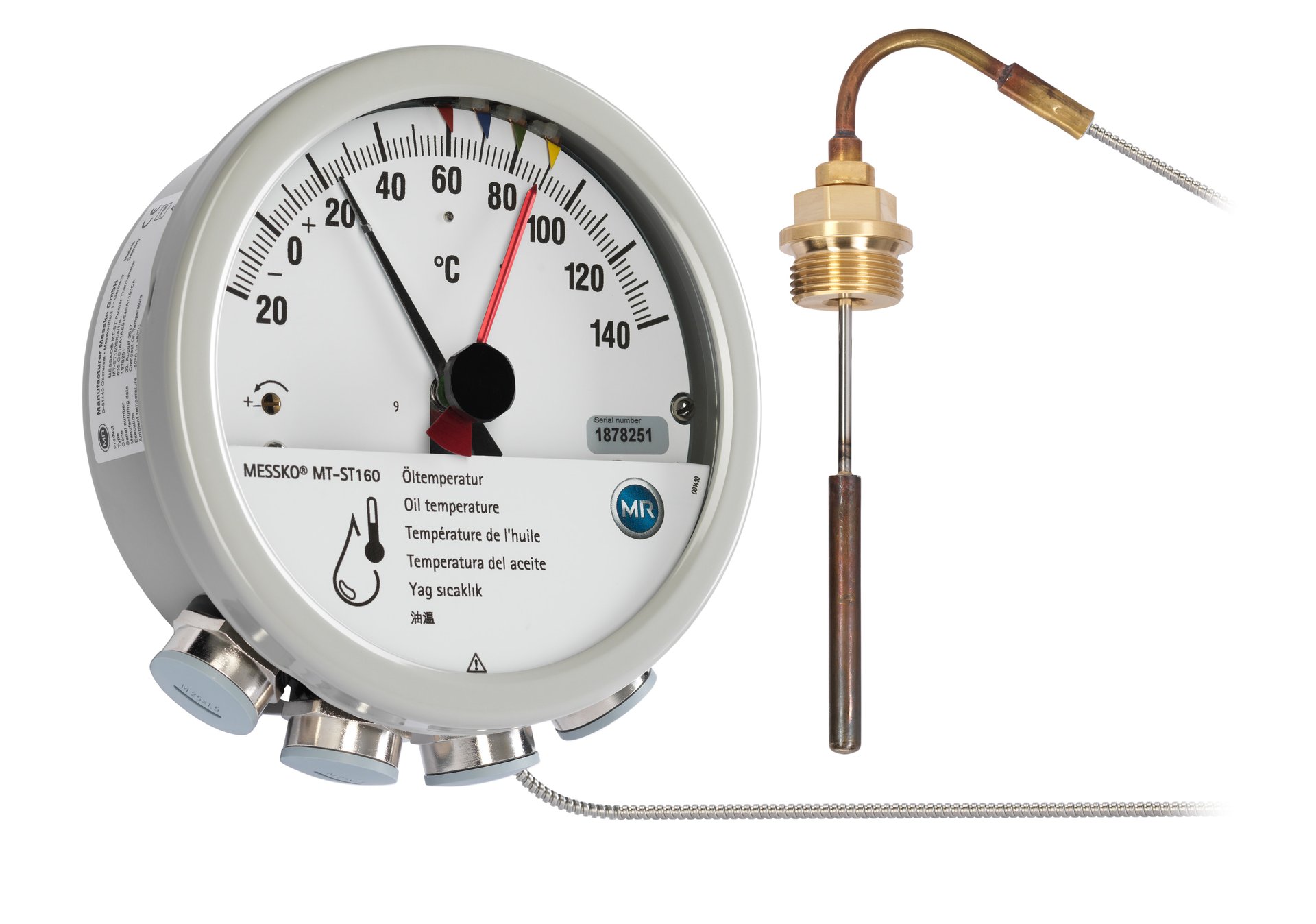

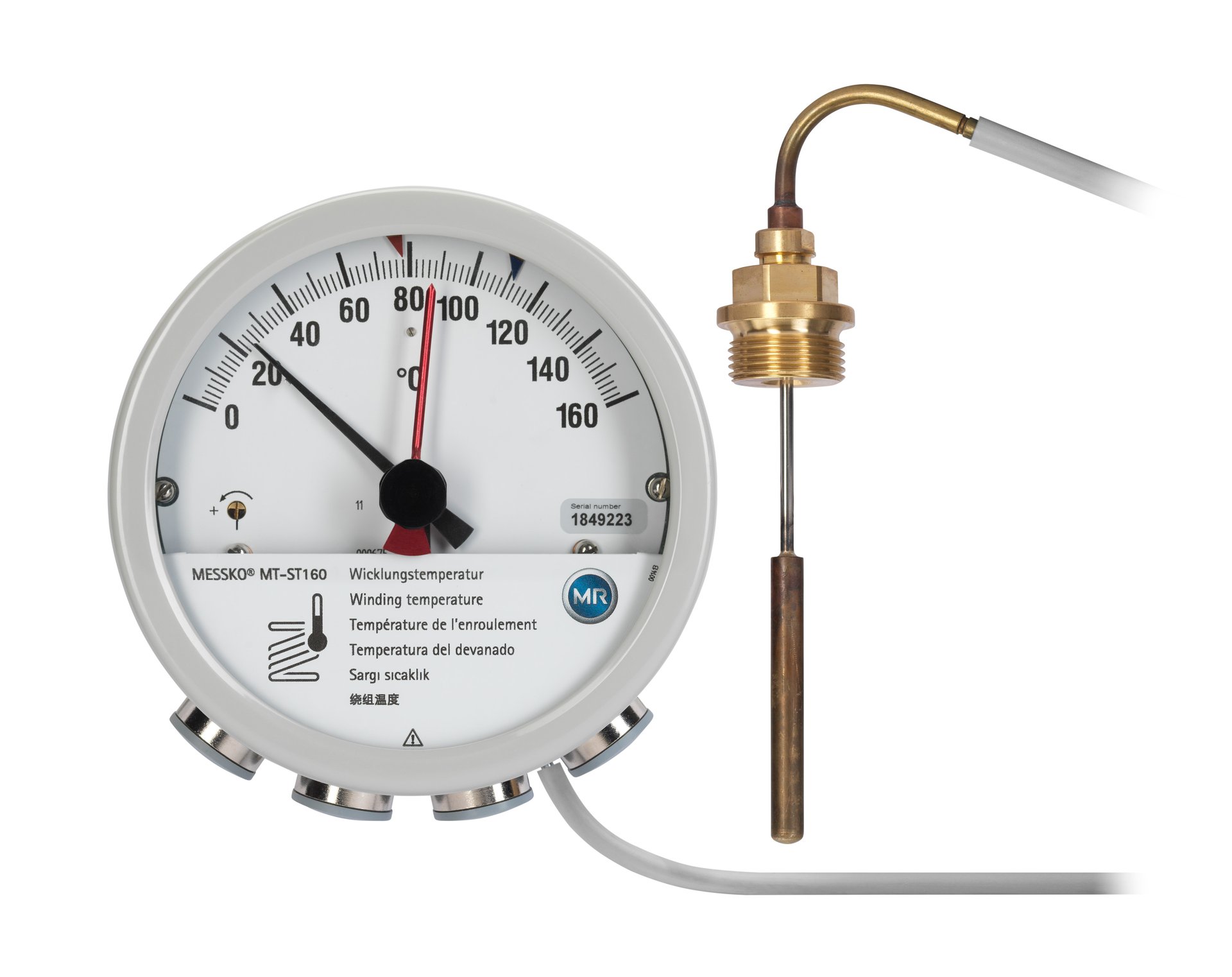

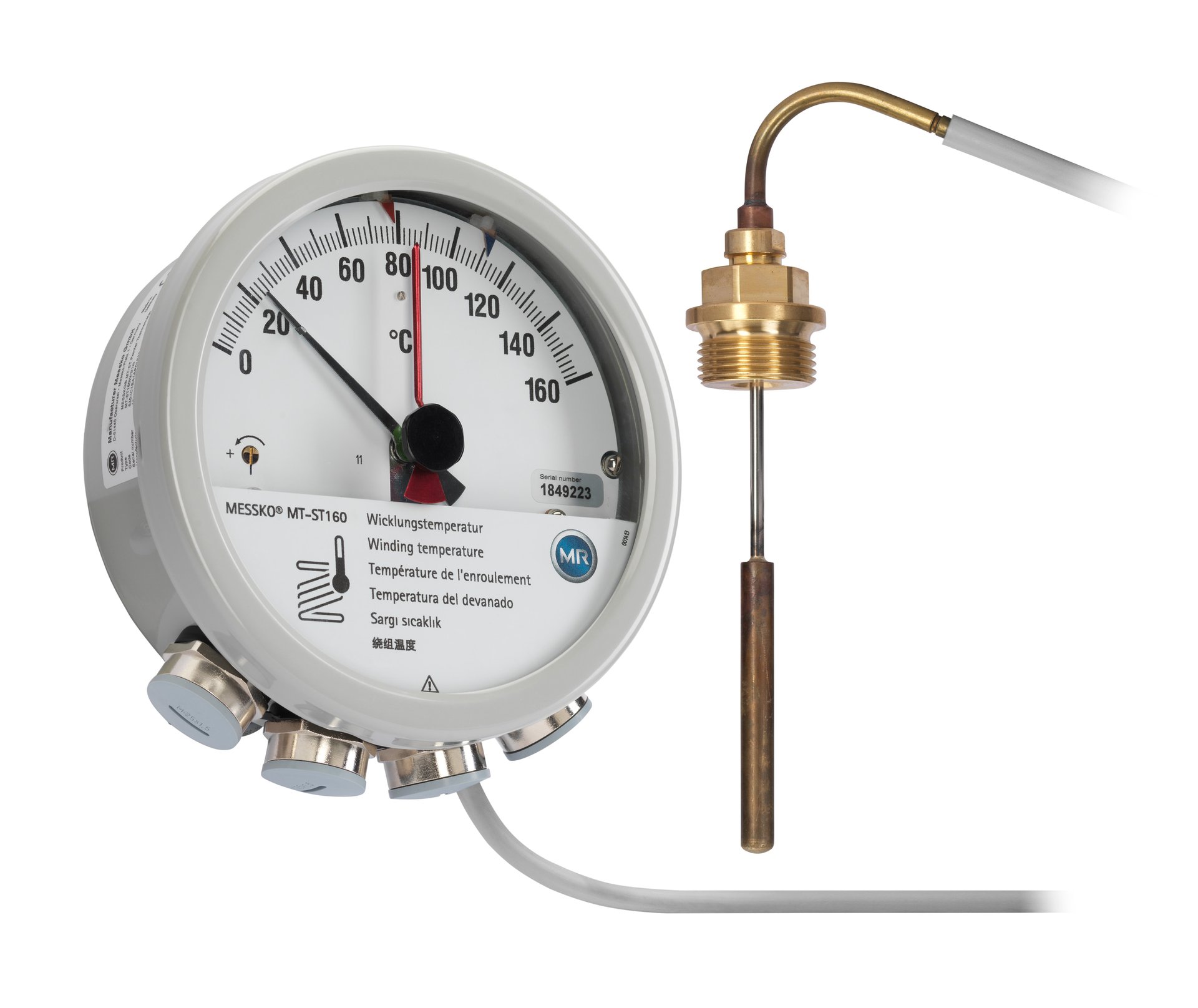

Modular temperature measuring system with direct display

MESSKO® COMPACT series devices prove their quality under extreme climatic conditions. The closed system allows measured values to be read off clearly even after decades – without readjustment or recalibration. The pointer thermometers with adjustable micro-switches reliably measure the oil and winding temperature (thermal image) in distribution and power transformers, reactors or similar applications. The mechanical measuring system functions without power and the compact design integrates all functions, including remote transmission – without any additional devices!

For special requirements in retrofitting projects see more details under MESSKO® Universal Retrofit Kit

Your Advantages at a Glance

-

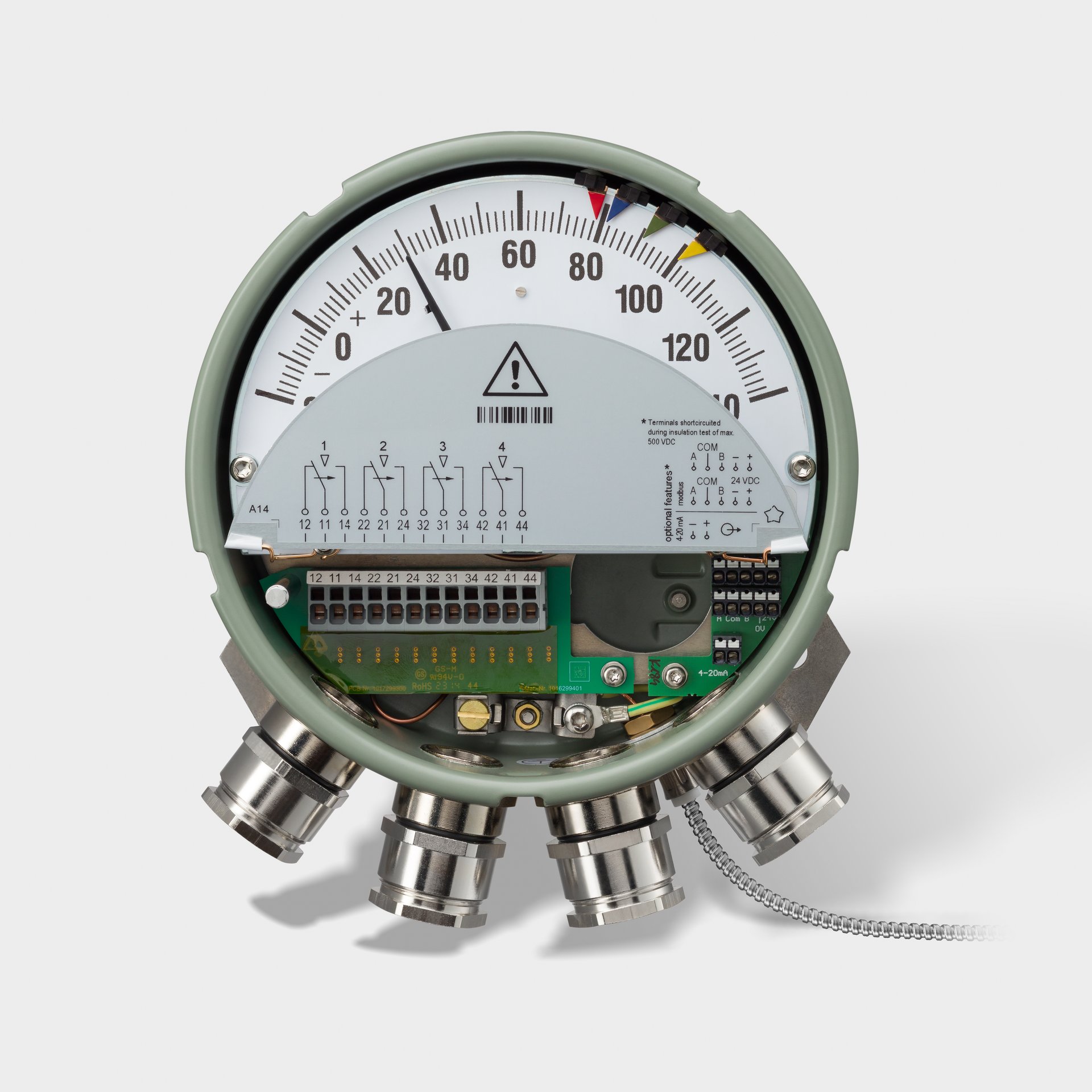

Optional outputs: RS485 Modbus RTU or 4...20 mA analog output

-

Extremely durable and reliable without readjustment or recalibration

-

Safe function even in case of vibrations and extreme outdoor conditions

-

Easy integration into ETOS® – Embedded Transformer Operating System

-

Simple configuration of gradients for the thermal image (WTI)

-

Sight glass consists of laminated safety glass with UV filter

-

Independent compensation for ambient temperature

-

Latest technology for precise signal transmission to the output

Product Information

| Housing (standard) | Galvanized sheet steel |

| Front ring and housing | Powder-coated, bayonet ring with silicone seal |

| Viewing glass | Composite safety glass with UV filter |

| Temperature sensor | Brass, bright, angled |

| Mounting plate | Stainless steel |

| Capillary tube | Copper capillary with PVC protective sleeve or stainless steel protective sleeve |

| Cable gland | 4 x M25 x 1.5 nickel-plated brass |

| Sensor gland | Double gland G1"B, brass, bright |

| Measurement range | -20 ... +140°C or 0 ... 160°C |

| Accuracy | ±3°C in accordance with DIN EN 13190 Class 1 and DIN 16196 |

| Installation | Indoors and outdoors, tropicalized |

| Ambient air temperature | -50 ... 80°C (compensated) |

| Operating temperature | -40 ... 80°C |

| Degree of protection | IP55 in accordance with IEC 60529 |

| Aeration | The viewing glass resists fogging up to 80% relative humidity thanks to an aerator |

| Drag hands | All thermometers are equipped with resettable drag hands, red |

| Weight | Approximately 2.5 kg (6 m capillary tube) |

| Switches | Two to six freely configurable micro-switches (of which up to four as changeovers) |

| Switching capacity | 230 V AC – making capacity: 250 VA, cos φ > 0,5 / breaking capacity: 60 VA, cos φ > 0,5 24…220 V DC – making capacity: 130 W, L/R < 40 ms / breaking capacity: 25 W, L/R < 40 ms |

| Switching capacity gold-plated contacts* | 230 V AC – switching capacity: max. 6,9 VA, cos φ = 0,9 24…220 V DC – switching capacity: max. 6,6 W, L/R < 25 ms *) Switching higher loads destroys the gold plating |

| Switching distance | 6% of the measuring range |

| Contact material | Silver alloy (AgNi10) |

| Rated insulation voltage | AC: 2,500 V / 1 min (terminals to ground) |

| Switching hysteresis | Approximately 5 K |

| Connection terminals | 0.25 - 2.5 mm² |

| Output | Digital - Modbus RTU via RS485 and analog - 4 ... 20 mA |

Select language

| Housing (standard) | Galvanized sheet steel |

| Front ring and housing | Powder-coated, bayonet ring with silicone seal |

| Viewing glass | Composite safety glass with UV filter |

| Temperature sensor | Brass, bright, angled |

| Mounting plate | Stainless steel |

| Capillary tube | Copper capillary with PVC protective sleeve or stainless steel protective sleeve |

| Cable gland | 4 x M25 x 1.5 nickel-plated brass |

| Sensor gland | Double gland G1"B, brass, bright |

| Measurement range | -20 ... +140°C or 0 ... 160°C |

| Accuracy | ±3°C in accordance with DIN EN 13190 Class 1 and DIN 16196 |

| Installation | Indoors and outdoors, tropicalized |

| Ambient air temperature | -50 ... 80°C (compensated) |

| Operating temperature | -40 ... 80°C |

| Degree of protection | IP55 in accordance with IEC 60529 |

| Aeration | The viewing glass resists fogging up to 80% relative humidity thanks to an aerator |

| Drag hands | All thermometers are equipped with resettable drag hands, red |

| Weight | Approximately 2.5 kg (6 m capillary tube) |

| Switches | Two to six freely configurable micro-switches (of which up to four as changeovers) |

| Switching capacity | 230 V AC – making capacity: 250 VA, cos φ > 0,5 / breaking capacity: 60 VA, cos φ > 0,5 24…220 V DC – making capacity: 130 W, L/R < 40 ms / breaking capacity: 25 W, L/R < 40 ms |

| Switching capacity gold-plated contacts* | 230 V AC – switching capacity: max. 6,9 VA, cos φ = 0,9 24…220 V DC – switching capacity: max. 6,6 W, L/R < 25 ms *) Switching higher loads destroys the gold plating |

| Switching distance | 6% of the measuring range |

| Contact material | Silver alloy (AgNi10) |

| Rated insulation voltage | AC: 2,500 V / 1 min (terminals to ground) |

| Switching hysteresis | Approximately 5 K |

| Connection terminals | 0.25 - 2.5 mm² |

| Output | Digital - Modbus RTU via RS485 and analog - 4 ... 20 mA |

Select language

MESSKO® Universal Retrofit Kit for any oil or winding gauge

MESSKO® Universal Retrofit Kit for any oil or winding gauge

The MESSKO® Universal Retrofit Kit is used to replace malfunctioning temperature gauges on transformers, reactors or similar devices. It is suitable for oil or winding temperature gauges. The Retrofit Kit consists of a gauge with a mechanical pointer that clearly shows the temperature.

Depending on the connection the same gauge can be used for either oil temperature indication or for winding temperature indication. A resettable maximum temperature indicator is standard.

Your advantages at a glance

Your advantages at a glance

- Optional output 4…20mA analog

- Easy temperature gauge replacement with a universal mounting bracket

- Thermo well sleeves ensure the probe fits exactly into your well

- Two different terminal covers allow you to simply indicate if the gauge is for oil or winding temperature

- Extremely durable and reliable without re-adjustment or recalibration

- Easy integration into ETOS®– Embedded Transformer Operating System

Technical Data Retrofit Kit

| Front ring and housing | Galvanized sheet steel, painted RAL 7038 in accordance with DIN EN ISO 12944-9 |

| Mounting plate | Aluminum, painted RAL 7038 |

| Capillary tube | Copper capillary with sheath |

| Cable gland | 4 x 3/4 - 14 NPT female thread |

| Sensor | Thin film load cell |

| Measurement range | 0 ... 160 °C (other measuring ranges available on request) |

| Degree of protection | IP 55 in accordance with IEC 60529 (similar to NEMA 4X) |

| Number | 3 or 4 adjustable microswitches |

| Output | Analog - 4... 20 mA (two wire system) |