Retrofit and Modernization

Retrofit. Turnkey. Customized.

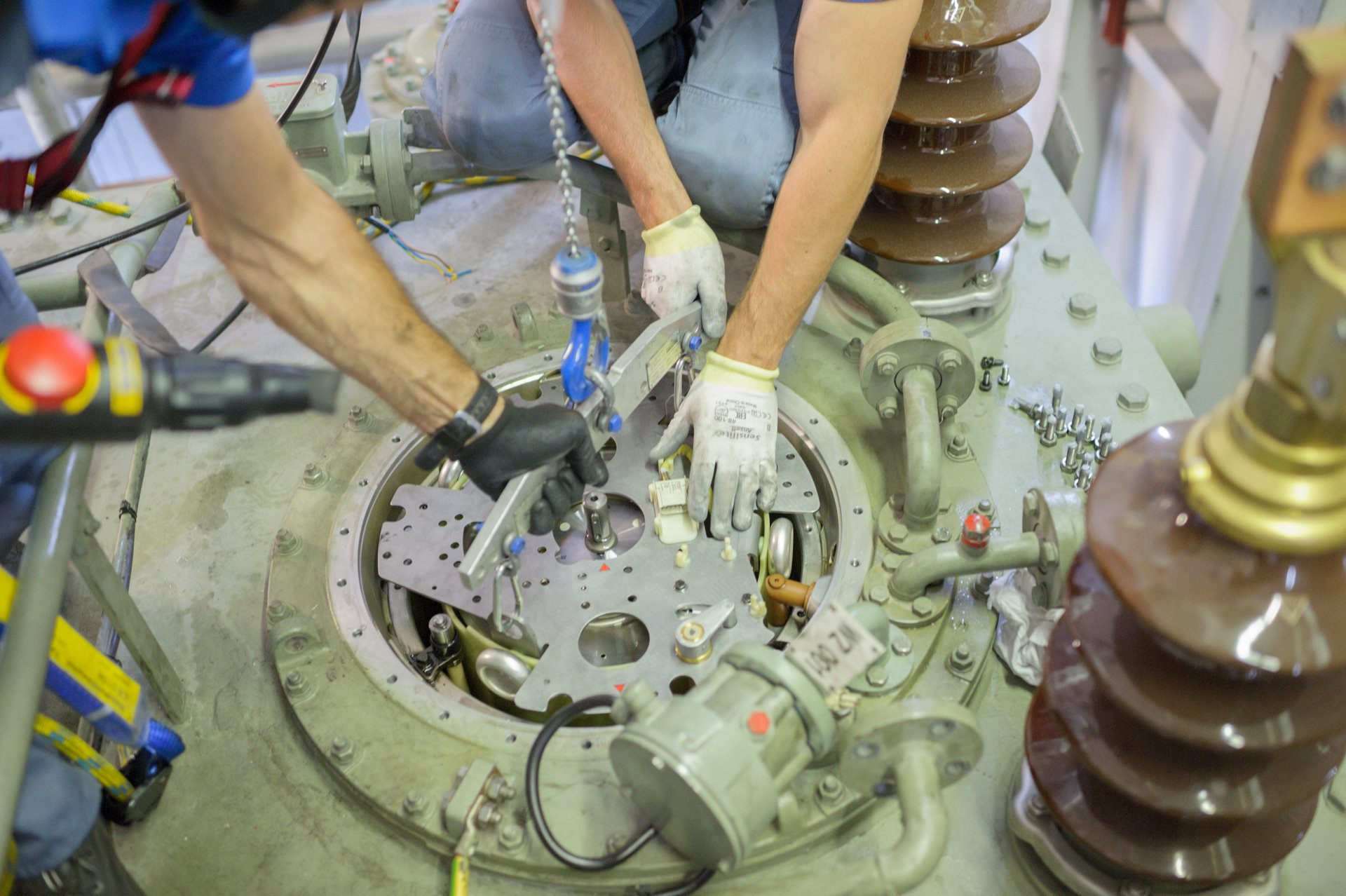

On-load tap-changers are key components for reliable operation of the transformer. Replacing an old on-load tap-changer cuts down on future maintenance costs and guarantees you easy spare parts supply. We offer turnkey retrofit solutions for reducing maintenance costs and increasing the reliability and service life of your transformer.

Your Advantages at a Glance

-

We offer retrofit solutions for older on-load tap-changers, including for types from manufacturers no longer in business

-

We deliver turnkey project implementation

-

Our customized replacement solutions make it possible for you to exchange conventional vacuum tap-changers with maintenance-free technology

-

Our retrofit solutions are economical, fast and reliable

-

Our retrofitting range includes the selector, the drive unit, the on-load tap-changer and the on-load tap-changer components

More Information

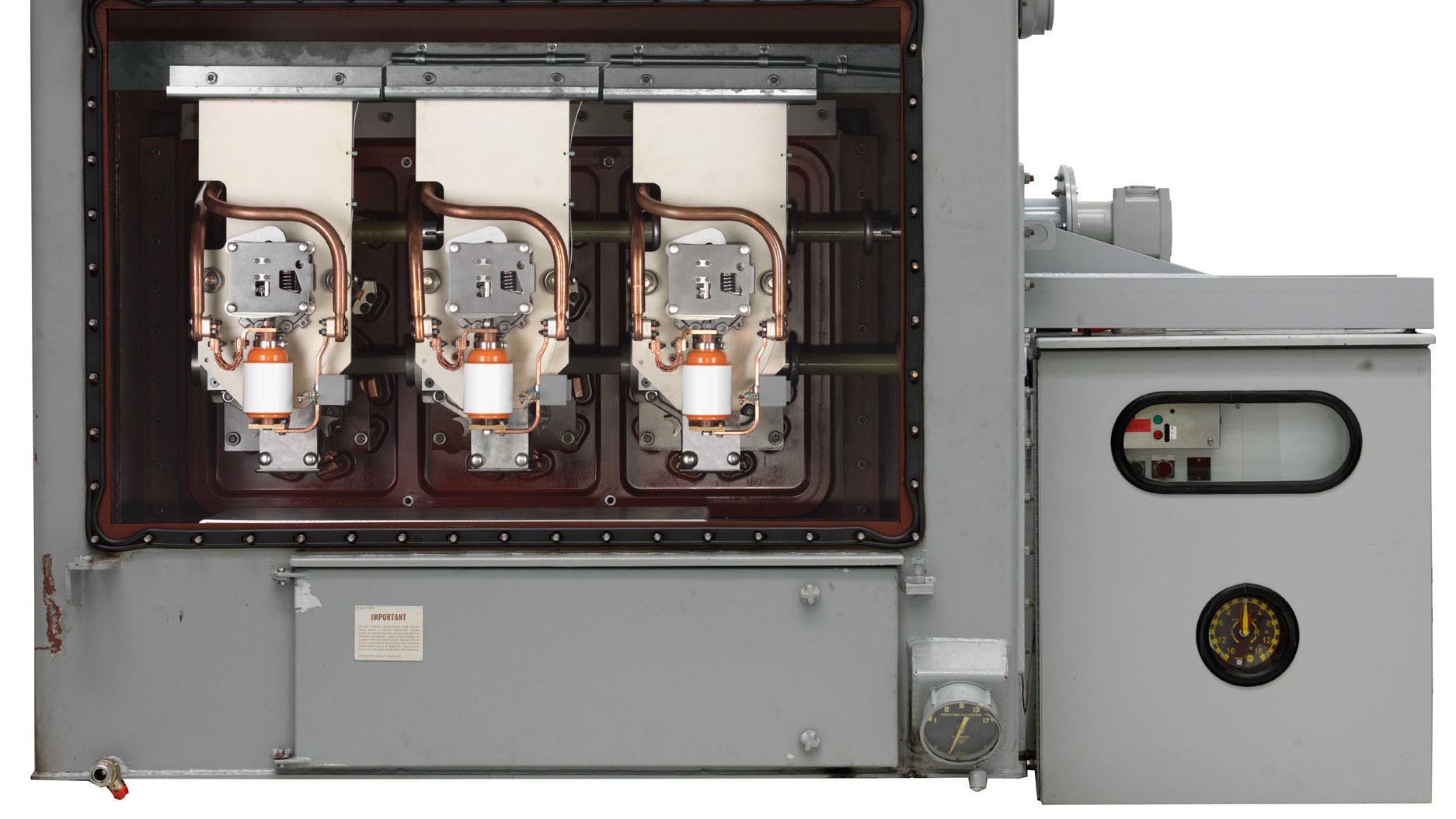

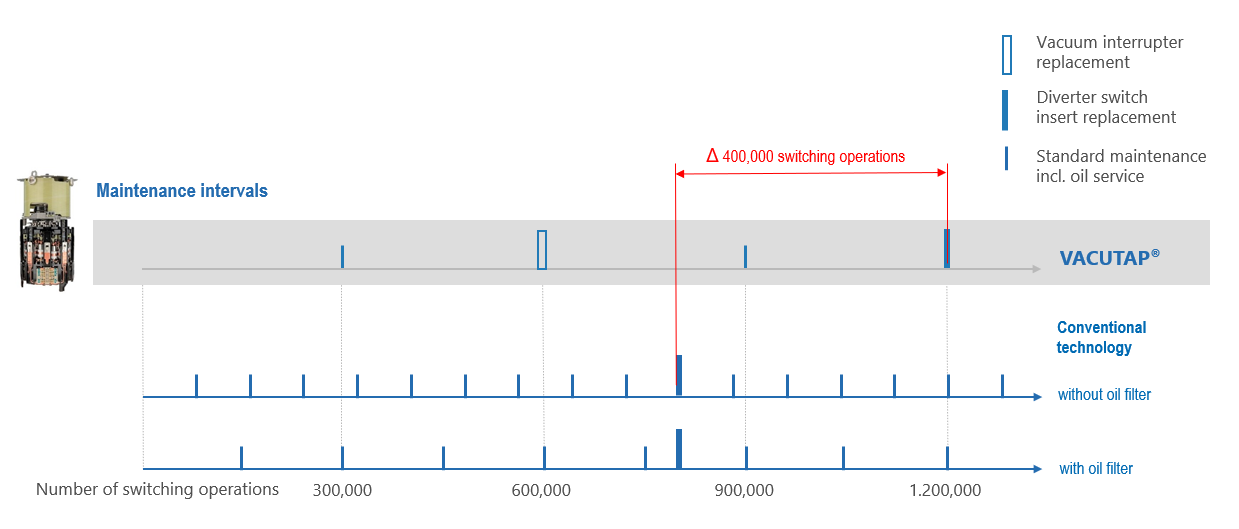

Oil on-load tap-changers come with a range of maintenance costs caused by oil carbonization, the replacement of contacts and oil filter systems that run concurrently with the tap changers. These problems are a thing of the past. By replacing your OILTAP ® diverter switch insert with a VACUTAP ® one, your maintenance costs are significantly reduced. Furthermore, the replacement of the diverter switch insert drastically reduces operating costs over the entire lifetime and increases the availability of your transformer.

Is your on-load tap-changer functioning properly, but the motor-drive unit is causing problems? Is your motor-drive unit aging, frequently requiring maintenance and are spare parts getting scarce? Do you want to integrate a voltage regulator or monitoring system and need an intelligent drive to do so? We have an optimal solution for all of these requirements: the TAPMOTION® ED / ETOS.

With a wide range of adapter and bracket solutions, we can exchange any motor-drive unit, whether old MR type MA2, 3 or 4 drives or drives from various manufacturers, such as ACEC, Alstom, Elin, Elprom, TRO or Trafo Union. After the work is complete, you have a maintenance-free motor-drive unit with proven MR quality, which offers maximum reliability.

Our monitoring solutions measure and calculate the most important operating states of the transformer and its components. This allows them to fulfill all current standards. Sensors can be connected via digital or analog inputs. The operating states are displayed locally in a web browser and can also be sent to the control room using conventional control system protocols.

Our monitoring solutions for the tap changer monitor motor-drive signals and the OLTC oil temperature. Furthermore, maintenance recommendations can be provided and maintenance intervals calculated for OILTAP® and VACUTAP® tap changers. Calculating the contact wear for OILTAP® tap changers is also possible. In addition, we can carry out vibro-acoustic analyses online and monitor the OLTC torque.

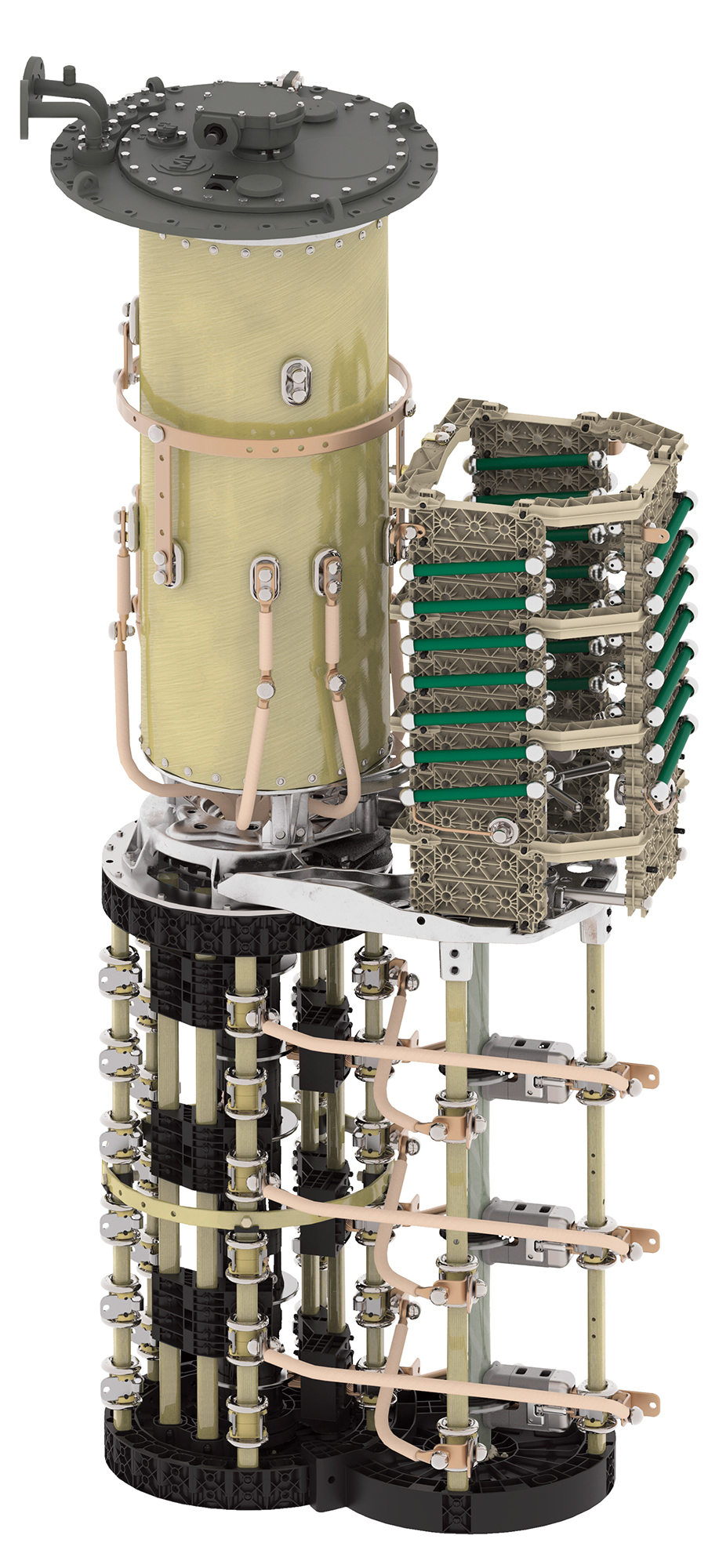

Many Westinghouse UTTs and UVTs were commissioned more than 40 years ago. Spare parts are expensive and difficult to come by. Experts are retiring and the technical knowledge is quickly being lost.

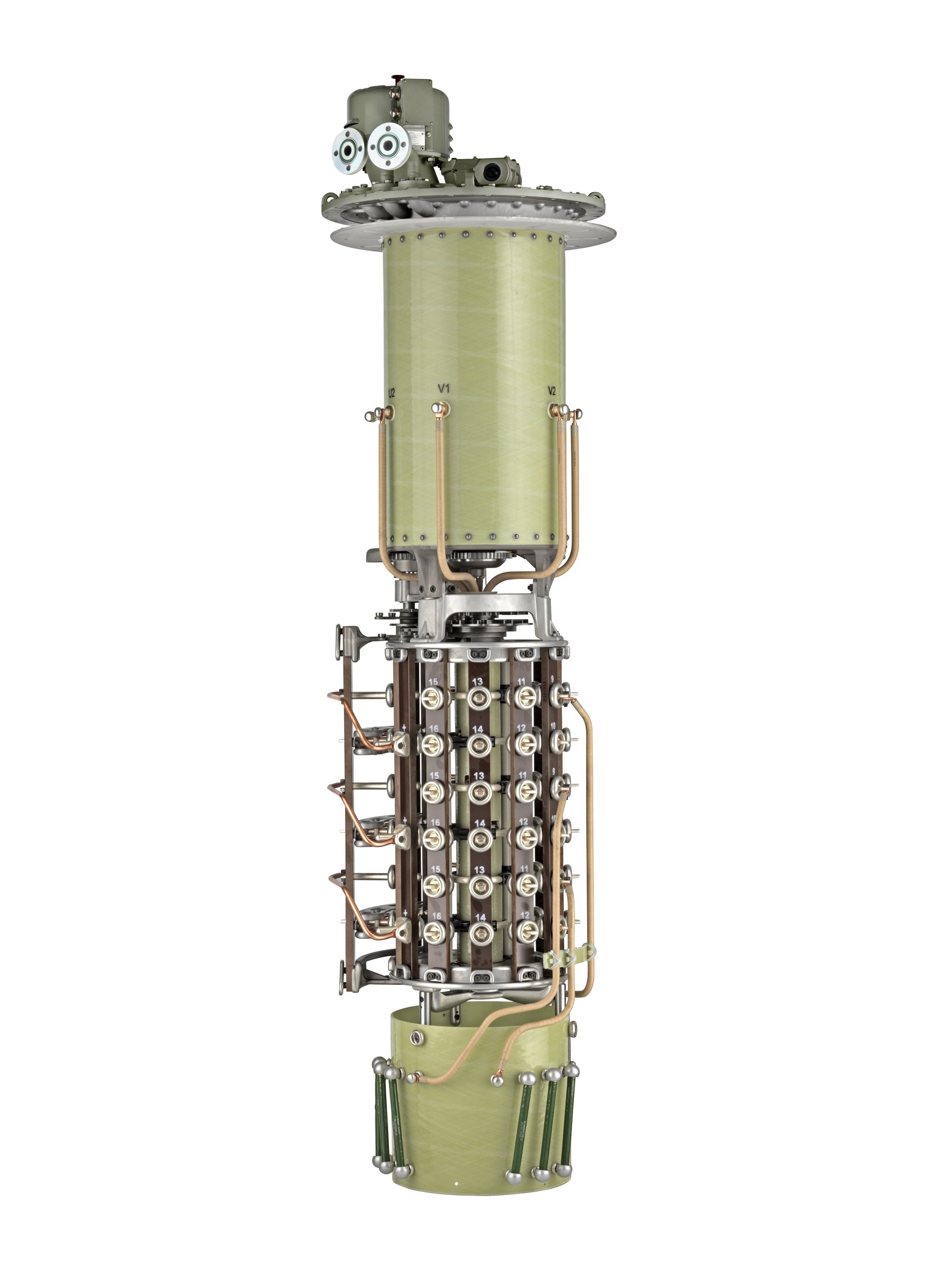

In view of these problems, MR offers the VACUTAP® UTT-LTX and VACUTAP® UVT-LTX products. These retrofit solutions ensure long-term reliability for your transformer fleet thanks to sophisticated, state-of-the-art technology.

On-load tap-changers are key components for reliable operation of the transformer. Replacing an old on-load tap-changer cuts down on high maintenance costs and guarantees you an easy spare parts supply for the future.

We offer turnkey retrofit solutions for reducing maintenance costs and increasing the reliability of your transformer.

Select language

Oil on-load tap-changers come with a range of maintenance costs caused by oil carbonization, the replacement of contacts and oil filter systems that run concurrently with the tap changers. These problems are a thing of the past. By replacing your OILTAP ® diverter switch insert with a VACUTAP ® one, your maintenance costs are significantly reduced. Furthermore, the replacement of the diverter switch insert drastically reduces operating costs over the entire lifetime and increases the availability of your transformer.

Is your on-load tap-changer functioning properly, but the motor-drive unit is causing problems? Is your motor-drive unit aging, frequently requiring maintenance and are spare parts getting scarce? Do you want to integrate a voltage regulator or monitoring system and need an intelligent drive to do so? We have an optimal solution for all of these requirements: the TAPMOTION® ED / ETOS.

With a wide range of adapter and bracket solutions, we can exchange any motor-drive unit, whether old MR type MA2, 3 or 4 drives or drives from various manufacturers, such as ACEC, Alstom, Elin, Elprom, TRO or Trafo Union. After the work is complete, you have a maintenance-free motor-drive unit with proven MR quality, which offers maximum reliability.

Our monitoring solutions measure and calculate the most important operating states of the transformer and its components. This allows them to fulfill all current standards. Sensors can be connected via digital or analog inputs. The operating states are displayed locally in a web browser and can also be sent to the control room using conventional control system protocols.

Our monitoring solutions for the tap changer monitor motor-drive signals and the OLTC oil temperature. Furthermore, maintenance recommendations can be provided and maintenance intervals calculated for OILTAP® and VACUTAP® tap changers. Calculating the contact wear for OILTAP® tap changers is also possible. In addition, we can carry out vibro-acoustic analyses online and monitor the OLTC torque.

Many Westinghouse UTTs and UVTs were commissioned more than 40 years ago. Spare parts are expensive and difficult to come by. Experts are retiring and the technical knowledge is quickly being lost.

In view of these problems, MR offers the VACUTAP® UTT-LTX and VACUTAP® UVT-LTX products. These retrofit solutions ensure long-term reliability for your transformer fleet thanks to sophisticated, state-of-the-art technology.

On-load tap-changers are key components for reliable operation of the transformer. Replacing an old on-load tap-changer cuts down on high maintenance costs and guarantees you an easy spare parts supply for the future.

We offer turnkey retrofit solutions for reducing maintenance costs and increasing the reliability of your transformer.

Select language

OLTC Retrofit and Refurbishment of 9 Power Transformers