Wartung und Inspektion

Damit die Spannung konstant bleibt

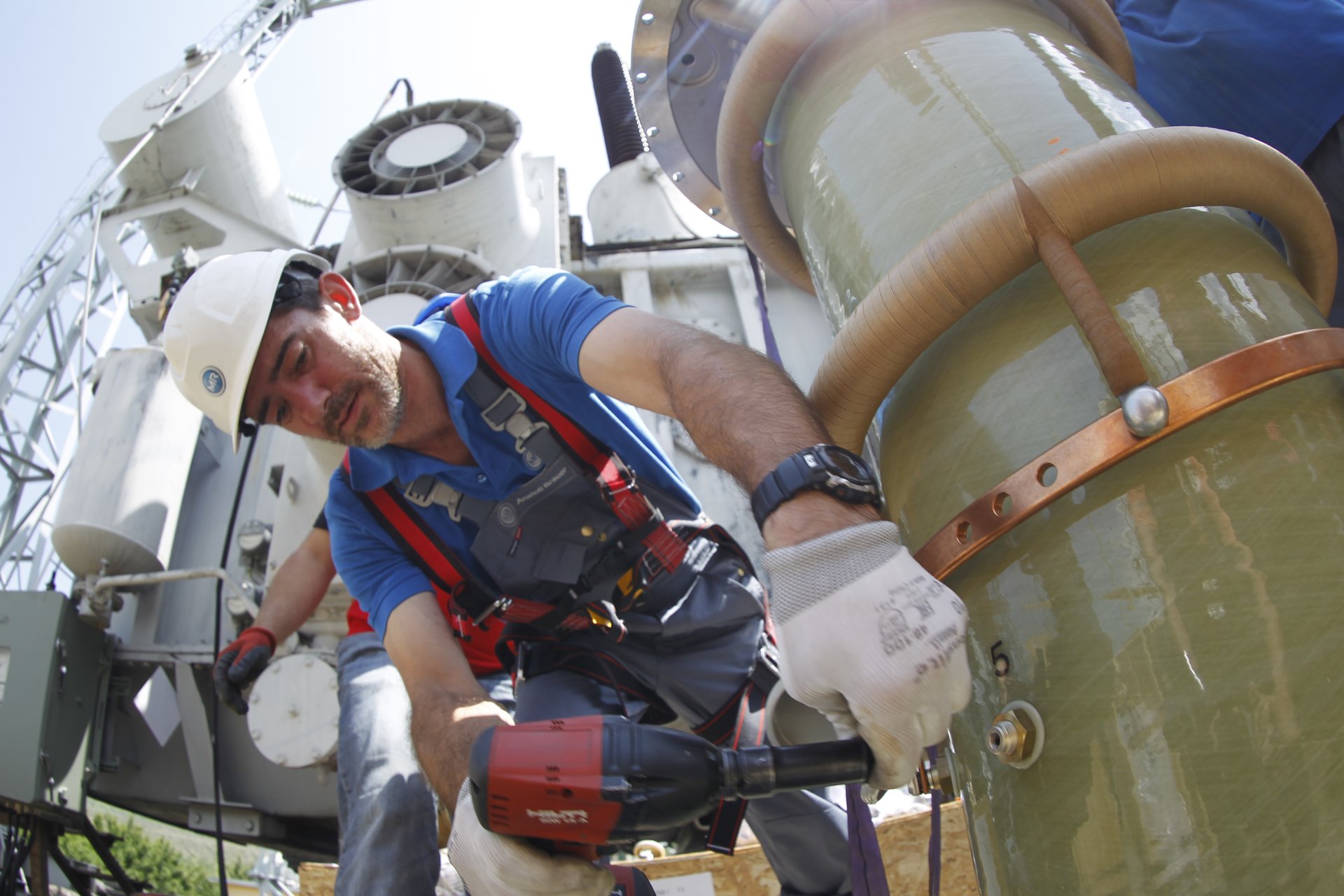

Um einen zuverlässigen Betrieb Ihres Leistungstransformators zu gewährleisten, muss der Laststufenschalter einwandfrei funktionieren. Um dies sicherzustellen, ist bei jedem Laststufenschalter, egal ob Öl oder Vakuum-Technologie, eine professionelle Wartung erforderlich.

Nutzen Sie hierfür unseren TESSA® OLTC Premium Service. Mit über 6.000 Laststufenschalter-Wartungen pro Jahr verfügen unsere speziell geschulten und geprüften Servicetechniker über eine einzigartige Felderfahrung. Ein ebenfalls einzigartig dichtes Netz von 21 Serviceniederlassungen weltweit garantiert darüber hinaus die schnelle Lieferung von Ersatzteilen, sowie eine 24/7-Erreichbarkeit.

Jetzt online auf myReinhausen anfragen

myReinhausen

Ihre Vorteile auf einen Blick

-

Störungsfrei

Unser OLTC Service garantiert einen störungsfreien Betrieb

-

Up to date

Mit OEM-Teilen wird Ihr Laststufenschalter auf den neusten Stand gebracht

-

Sicher

Sie erhalten 24 Monate Gewährleistung auf unsere Service-Tätigkeiten

-

Herstellerunabhängig

Service für alle Arten, Marken und Modelle von Laststufenschaltern

-

Konform

Unser Service ist u.a im Einklang mit DIN EN ISO 9001 und 14001

-

Schnell

Wir sind in der Regel innerhalb von weniger als 24 Stunden vor Ort

Mehr Informationen

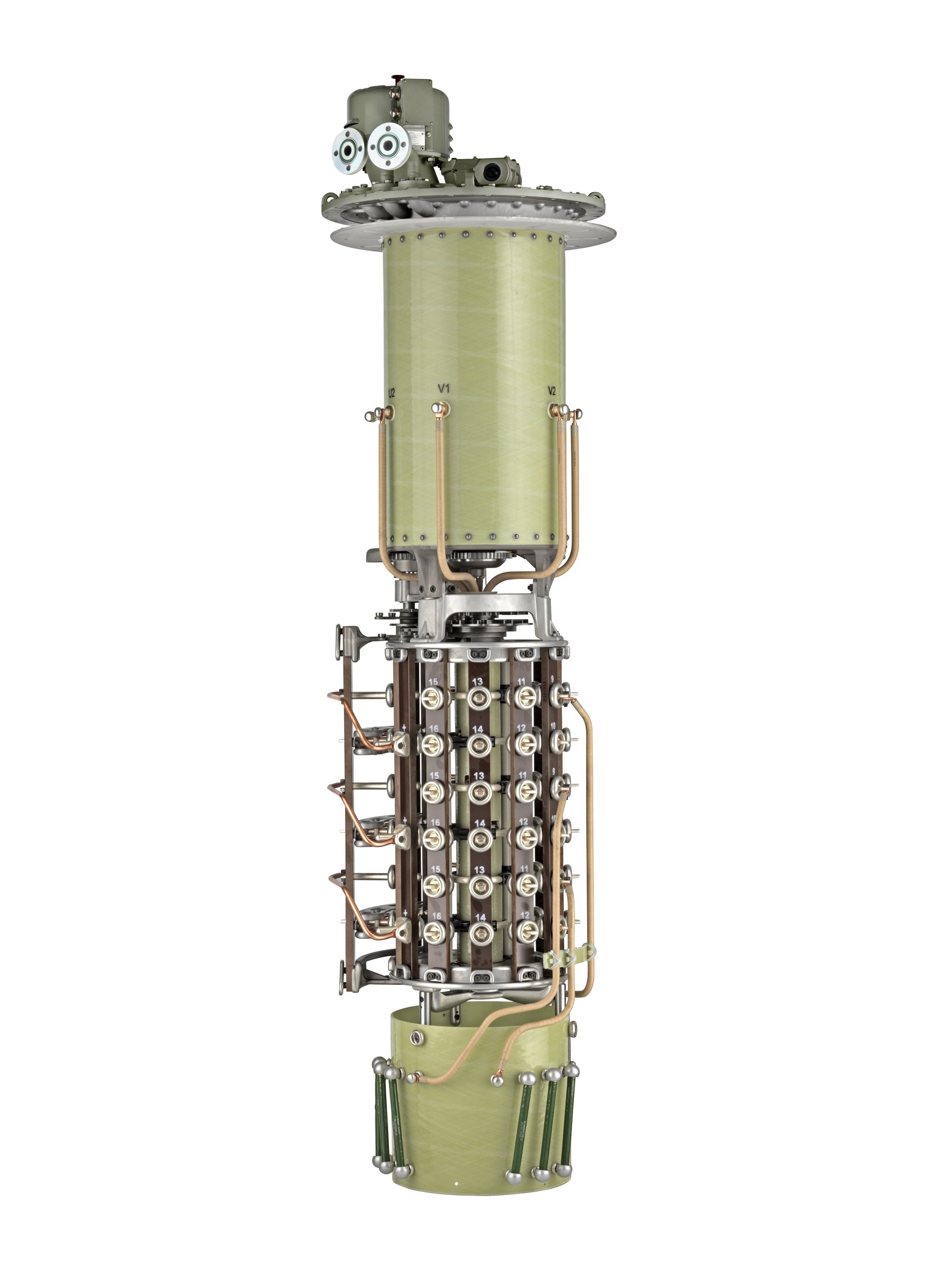

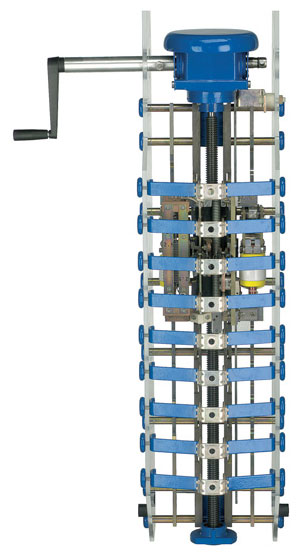

Unsere OILTAP®-Laststufenschalter zeichnen sich durch ihre robuste Bauweise, die vielseitigen Einsatzmöglichkeiten und der erprobten Langlebigkeit aus. Unsere Öl-Laststufenschalter sind viele Jahrzehnte lang in Betrieb. Bedingt durch die langen Laufzeiten werden immer häufiger die Schaltzahlen und Zeitintervalle erreicht, die das entscheidende Wartungskriterium darstellen. Wir bieten deshalb verschiedene Hilfsmittel für die Inspektion und Wartung von OILTAP®- Laststufenschalter an.

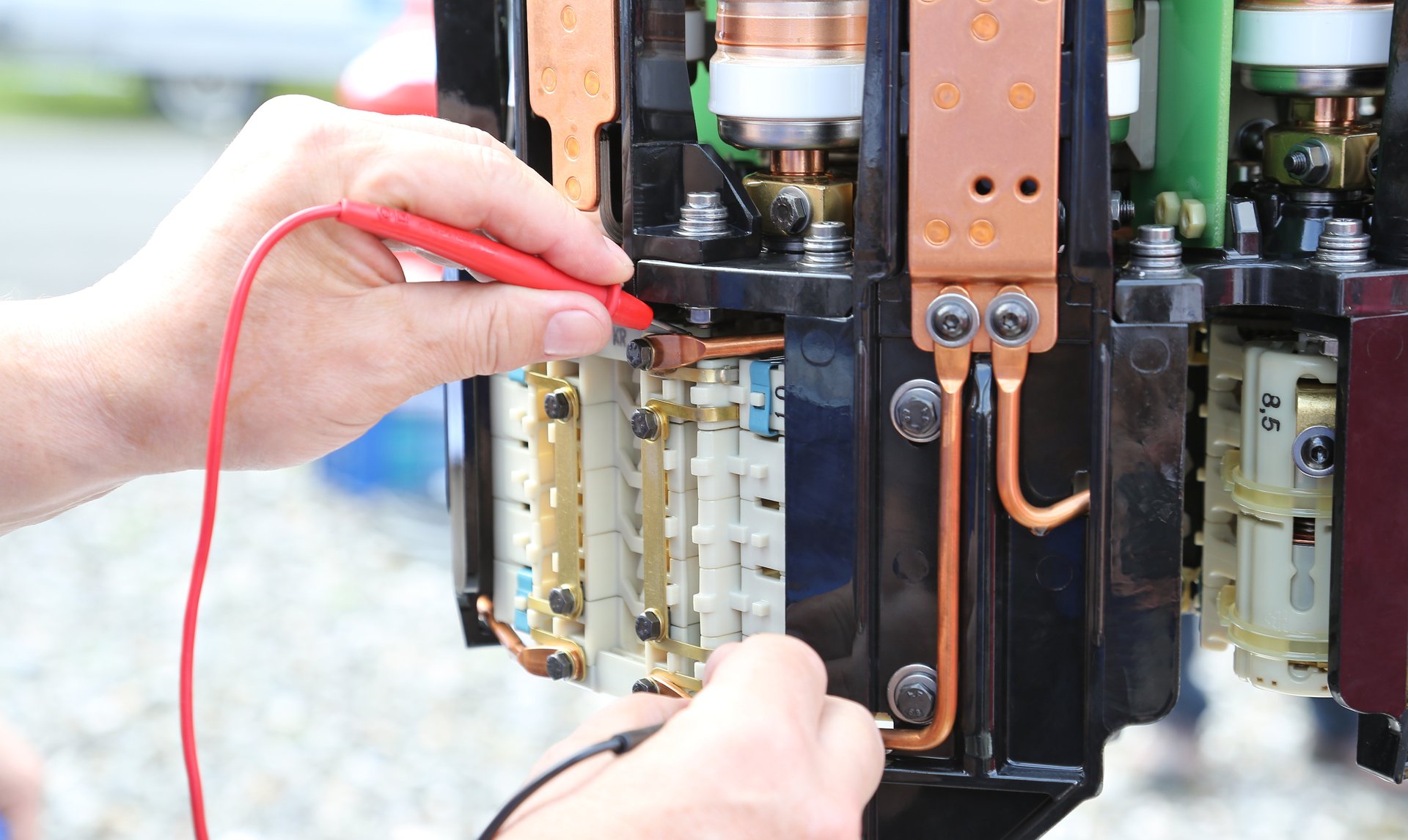

Die Inspektions- und Wartungsarbeiten lassen sich dabei ideal mit elektrischen Messungen für den Laststufenschalter kombinieren. Für ölgefüllte Laststufenschalter bieten sich die viborakustische Messung (VAM) sowie die Dynamische Widerstandsmessung (DRM) an.

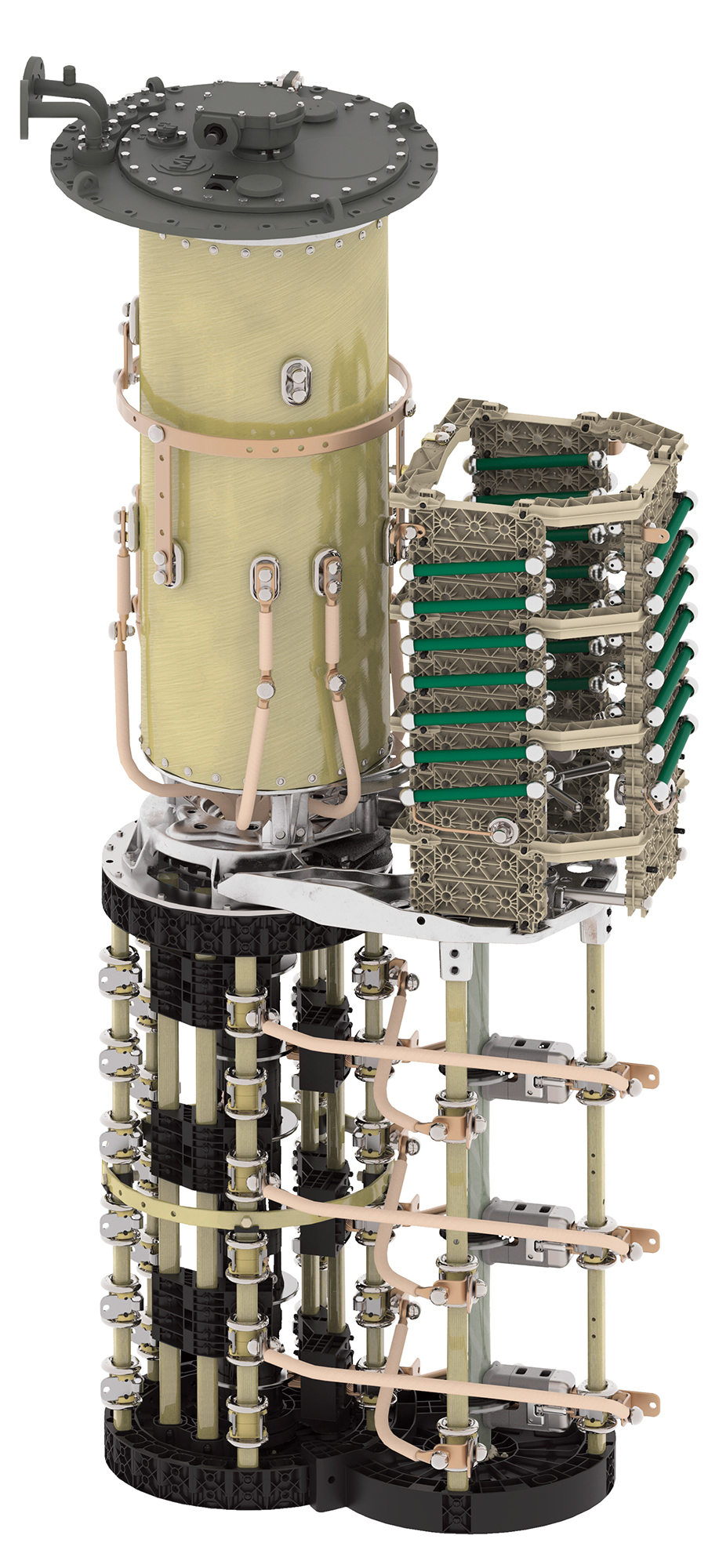

Unsere VACUTAP®-Laststufenschalter werden in mehreren High-End-Anwendungen verwendet, z.B. in strategisch wichtigen Transformatoren des Energieübertragungsnetzes oder in der Schwerindustrie. Für solche kritischen Anwendungen müssen Zuverlässigkeit, Verfügbarkeit und der sichere Betrieb jederzeit gewährleistet sein. Deshalb bieten wir in unserem Portfolio verschiedene Instrumente zur Zustandsbewertung und Wartung an. Ein Rundum-Paket umfasst verschiedene Tests, wie eine dynamische Widerstandsmessung (DRM), eine vibroakustische Messung (VAM) und weitere Diagnosemessungen (z.B. Öl-Analyse & Elektrische Messungen).

Wir bieten Ihnen ein Rundum-sorglos-Paket! Neben OEM-Ersatzteilen und Öl-Handling stellen wir sowohl zwei qualifizierte Service-Experten als auch einen Kran zur Verfügung.

Ihre Vorteile:

1. Konzentration Ihrer Ressourcen aufs Kerngeschäft

2. Reduzierung Ihrer Gesamtaufwendungen

3. Höchste Qualität bei Auslagerung Ihrer Dienstleistung an MR

4. Kombinationsmöglichkeiten mit weiteren Dienstleistungen am Transformator

5. Abgabe Ihres Geschäftsrisikos an MR – 2 Jahre Gewährleistung

6. Wetterunabhängige Durchführung der Wartung durch LKW

Wir führen Wartungen an folgenden Laststufenschaltern durch: Alle Typen der Maschinenfabrik Reinhausen; Trafo Union/TUSA/AEG; Elin; Elprom/Hyundai Elprom; Westinghouse; General Electric/Canadian GE; Ferranti/Ferranti Packard; Siemens/Allis Chalmers; ABB/Asea/BBC/Waukesha SPX; Alstom; Mitsubishi, Toshiba; Fuji/Fuji-TU; Hitachi; Brush/ATL; McGraw Edison; Federal Pacific/Federal Pioneer; ZTR; Hawker Siddley; ACEC; Weitere Typen von Altschaltern ehemaliger Hersteller

Die Inspektions- und Wartungsarbeiten lassen sich ideal mit elektrischen Messungen für den Laststufenschalter kombinieren. Für ölgefüllte Laststufenschalter bieten sich die viborakustische Messungen (VAM) sowie die Dynamische Widerstandsmessung (DRM). Bei einem Vakuum-Laststufenschalter bietet sich eine Kombination aus viborakustischer Messung (VAM), dynamischer Widerstandsmessung (DRM) sowie der Messung der Vakuumröhren an.

Im Falle einer notwendigen Wählerwartung kann der komplette Service aus einer Hand geliefert werden:

- Abpumpen des Öls (mit Ausgleich durch Trockenluft) aus dem Trafo in externe Tanks

- Öffnen oder ggf. auch Einbringen von Mannlöchern zum Einstieg für die Wartung

- Wartung der Wähler im eingebauten Zustand

- Abdichtung und schließen der Mannlöcher

- Rekonditionierung des Öls (filtern, entgasen, trocknen)

- Einsaugen des Öls nach einer Vakuumphase unter Vakuum oder Teilvakuum

- Entlüftung des Transformators

- Ölprobennahmen mit Analysen vor und nach der Wartung.

Sprache wählen

Unsere OILTAP®-Laststufenschalter zeichnen sich durch ihre robuste Bauweise, die vielseitigen Einsatzmöglichkeiten und der erprobten Langlebigkeit aus. Unsere Öl-Laststufenschalter sind viele Jahrzehnte lang in Betrieb. Bedingt durch die langen Laufzeiten werden immer häufiger die Schaltzahlen und Zeitintervalle erreicht, die das entscheidende Wartungskriterium darstellen. Wir bieten deshalb verschiedene Hilfsmittel für die Inspektion und Wartung von OILTAP®- Laststufenschalter an.

Die Inspektions- und Wartungsarbeiten lassen sich dabei ideal mit elektrischen Messungen für den Laststufenschalter kombinieren. Für ölgefüllte Laststufenschalter bieten sich die viborakustische Messung (VAM) sowie die Dynamische Widerstandsmessung (DRM) an.

Unsere VACUTAP®-Laststufenschalter werden in mehreren High-End-Anwendungen verwendet, z.B. in strategisch wichtigen Transformatoren des Energieübertragungsnetzes oder in der Schwerindustrie. Für solche kritischen Anwendungen müssen Zuverlässigkeit, Verfügbarkeit und der sichere Betrieb jederzeit gewährleistet sein. Deshalb bieten wir in unserem Portfolio verschiedene Instrumente zur Zustandsbewertung und Wartung an. Ein Rundum-Paket umfasst verschiedene Tests, wie eine dynamische Widerstandsmessung (DRM), eine vibroakustische Messung (VAM) und weitere Diagnosemessungen (z.B. Öl-Analyse & Elektrische Messungen).

Wir bieten Ihnen ein Rundum-sorglos-Paket! Neben OEM-Ersatzteilen und Öl-Handling stellen wir sowohl zwei qualifizierte Service-Experten als auch einen Kran zur Verfügung.

Ihre Vorteile:

1. Konzentration Ihrer Ressourcen aufs Kerngeschäft

2. Reduzierung Ihrer Gesamtaufwendungen

3. Höchste Qualität bei Auslagerung Ihrer Dienstleistung an MR

4. Kombinationsmöglichkeiten mit weiteren Dienstleistungen am Transformator

5. Abgabe Ihres Geschäftsrisikos an MR – 2 Jahre Gewährleistung

6. Wetterunabhängige Durchführung der Wartung durch LKW

Wir führen Wartungen an folgenden Laststufenschaltern durch: Alle Typen der Maschinenfabrik Reinhausen; Trafo Union/TUSA/AEG; Elin; Elprom/Hyundai Elprom; Westinghouse; General Electric/Canadian GE; Ferranti/Ferranti Packard; Siemens/Allis Chalmers; ABB/Asea/BBC/Waukesha SPX; Alstom; Mitsubishi, Toshiba; Fuji/Fuji-TU; Hitachi; Brush/ATL; McGraw Edison; Federal Pacific/Federal Pioneer; ZTR; Hawker Siddley; ACEC; Weitere Typen von Altschaltern ehemaliger Hersteller

Die Inspektions- und Wartungsarbeiten lassen sich ideal mit elektrischen Messungen für den Laststufenschalter kombinieren. Für ölgefüllte Laststufenschalter bieten sich die viborakustische Messungen (VAM) sowie die Dynamische Widerstandsmessung (DRM). Bei einem Vakuum-Laststufenschalter bietet sich eine Kombination aus viborakustischer Messung (VAM), dynamischer Widerstandsmessung (DRM) sowie der Messung der Vakuumröhren an.

Im Falle einer notwendigen Wählerwartung kann der komplette Service aus einer Hand geliefert werden:

- Abpumpen des Öls (mit Ausgleich durch Trockenluft) aus dem Trafo in externe Tanks

- Öffnen oder ggf. auch Einbringen von Mannlöchern zum Einstieg für die Wartung

- Wartung der Wähler im eingebauten Zustand

- Abdichtung und schließen der Mannlöcher

- Rekonditionierung des Öls (filtern, entgasen, trocknen)

- Einsaugen des Öls nach einer Vakuumphase unter Vakuum oder Teilvakuum

- Entlüftung des Transformators

- Ölprobennahmen mit Analysen vor und nach der Wartung.

Sprache wählen