-

Impulses

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

- Lifetime optimization

- Power supply in industry

- Globalization

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

-

Lifetime optimization

-

Power supply in industry

-

Globalization

Impulses - Portfolio

-

Career

Career

-

Company

Company

PQ provides high voltage inrush current limiting resistor for rectifier transformer

The production of chemical products and the production processes demanding very often for powerful electrolyzer systems. These electrolyzer units are mainly operated with a DC voltage below 1000 V and operating currents ranging between a few kA up to 3 digit kA values. Due to these parameters the power consumption of electrolyzer plant are typically in a range of several MW´s. The network connection is realized with powerful rectifiers and associated rectifer transformer.

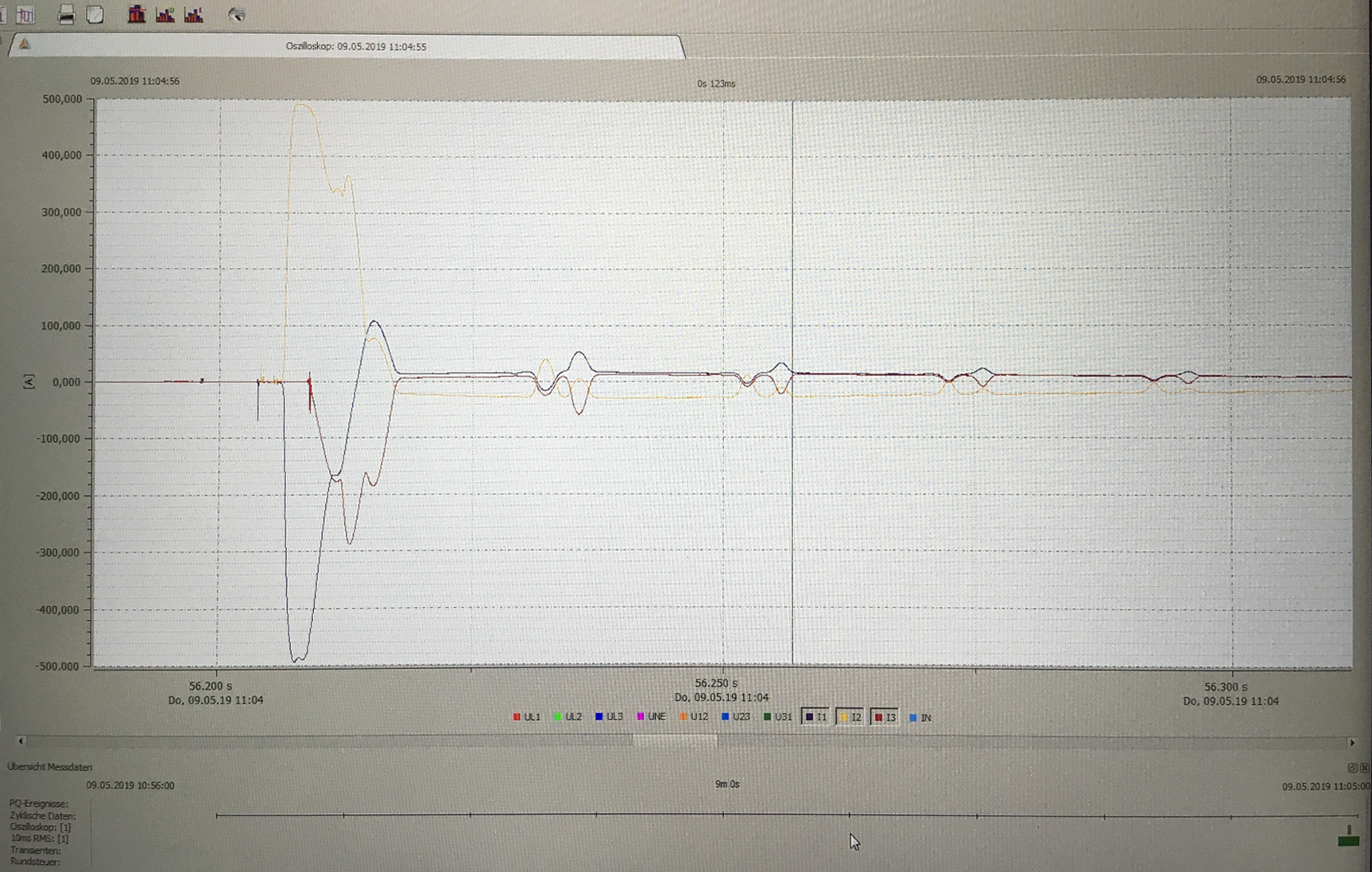

In the specific project case the customer built up a complete new eletrolyzer line with a nominal power of 57.2 MVA. Once all the equipment have been installed, the first energization of the rectifier transformer was scheduled. During the energization sequence the peak inrush current of the rectifier transformer was unexpectedly high and reached values of around 3000 A at the 75 kV busbar. This value was more than five-times higher than allowed. As one of the next steps, the customer has changed the circuit breaker from a standard breaker to a point-of-wave breaker type. But even this measure brought not the expected results. Finally the customer consulted MR-PQ for further support.

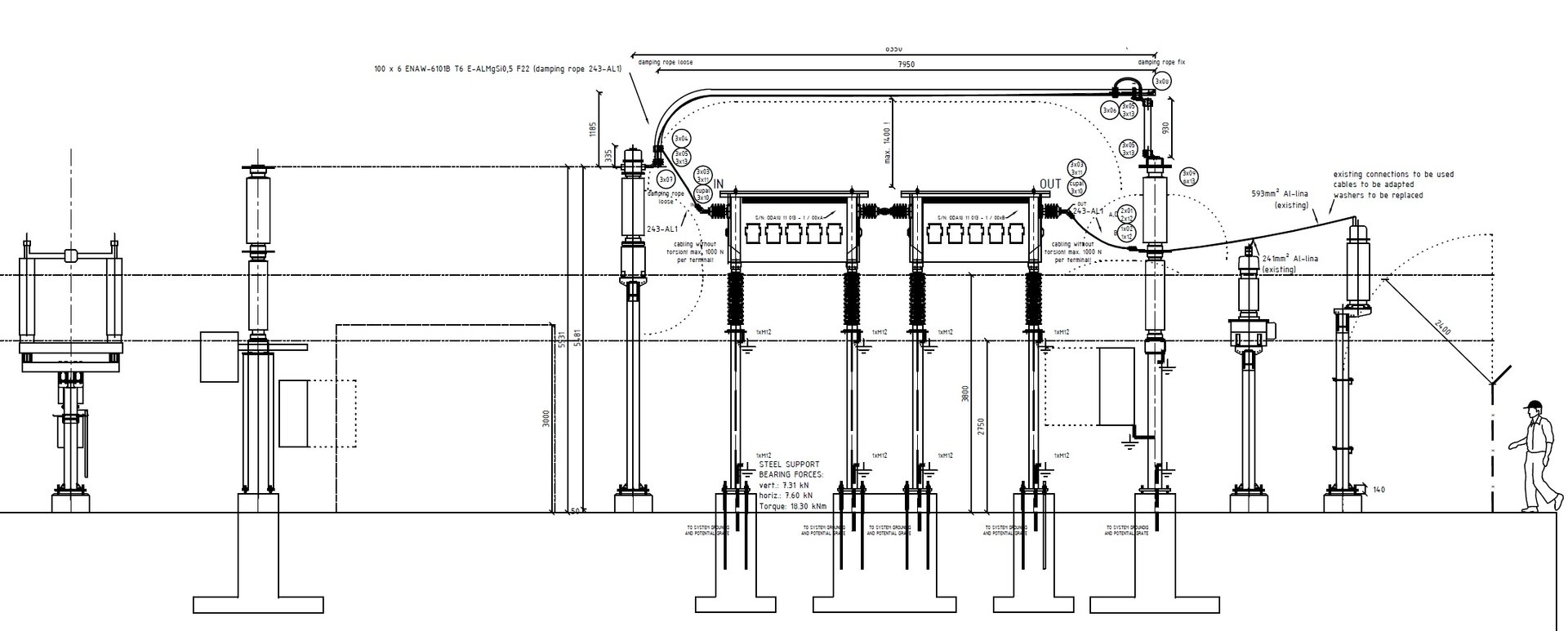

MR-PQ´s starts the investigation of the network with a comprehensive study in order to reproduce the inrush behaviour of the transformer using the measurement results done by the client. After finishing, it has been decided installing a 75 kV Inrush Limit-ing Resistor system with a by-pass breaker in serial to the rectifier transformer.

Challenging for the project were the limited space at site and the clear request of the customer not to modify the existing 75 kV busbar.

MR-PQ could solved the problem in a way that the whole solution fits into the existing feeder yard. So even the initially intended spare breaker for connecting the by-pass breaker could be saved.

As the customer has only 2-3 slots/year for shutting off the 75 kV busbar for mainte-nance work, the timeframe was very tough. MR-PQ was awarded in November 2018 with the clear task to set the whole system into operation by begin of May 2019. The scope of supply were not only the resistor units. Moreover MR-PQ had to provide the whole detail engineering with layout drawings, wiring books and coordination of a sub-contracted local third party at site (responsible for the civil and installation work).

The years of experiences of the MR-PQ engineering team for complex projects were finally the key to success and ensured that the whole project have been delivered and installed on time.

Before the rectifier transformer could be energized again, MR-PQ´s commissioning engineers have checked the whole installation (mechanical/electrical) and installed a measurement device in order to record the current values during the energization sequence. Finally the measurement results confirm the performance of the solution, as the re-sulting peak inrush current has been reduced from initial ~ 3000 A down to 500 A. Because of that fact the voltage drop in the 75 kV network could reduced as well.

Finally the customer was very satisfied with MR-PQ´s work and got the release for operation of the new rectifier line from the local utility.

| R.Rund@reinhausen.com |

We are here for you. Wherever you are.

Looking for the right contact partner?

Do you have a concern, but don't know whom you should contact? You will find that information in our contact overview. In the event of any technical disturbances, our 24/7 support is always at your disposal.

Welcome to myReinhausen

myReinhausen is MR's central, digital customer platform. On myReinhausen, customers can access customer-specific MR information as well as numerous free features related to the MR portfolio.

myReinhausenJoin Reinhausen family

Find your ideal job quickly!

Check our vacancies here. Apply today and contribute at the world market leader in energy technology keeping the energy supply stable in the future.