-

Impulses

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

- Lifetime optimization

- Power supply in industry

- Globalization

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

-

Lifetime optimization

-

Power supply in industry

-

Globalization

Impulses - Portfolio

-

Career

Career

-

Company

Company

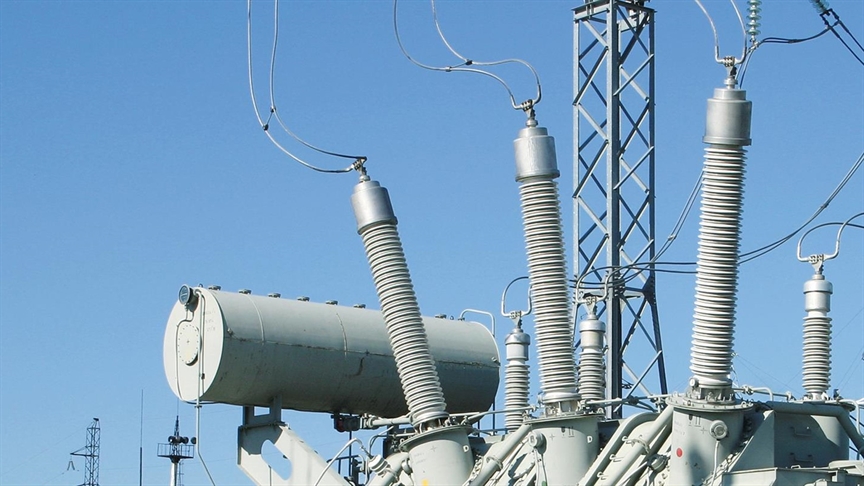

Greater security for your bushings

Continuous online monitoring with MSENSE® BM / ETOS® BM

According to CIGRÉ, damage to high-voltage bushings is responsible for 17 percent of transformer failures. Since increasing demands on the grid require that transformers operate absolutely reliably, it is therefore all the more important to continuously record and evaluate the condition of the bushings - with MSENSE® BM / ETOS® BM.

MSENSE® BM / ETOS® BM online monitoring detects faults, aging and failure risks at an early stage and provides recommendations for action before the transformer is damaged.

Monitoring of high-voltage bushings usually takes place offline and once a year. This presents a high risk because during the long pauses between inspections, previous damage and aging processes can develop negatively or escalate unnoticed with the result that new damage is not detected in time. The MSENSE® BM online monitoring system permanently monitors the condition of the bushings by measuring relevant variables directly on oil-impregnated paper bushings (OIP), resin-impregnated paper bushings (RIP) or resin-impregnated synthetic bushings (RIS/RIF) of voltage levels 66...420 kV*. This means: reduced costs due to predictable maintenance.

MSENSE® BM-C / ETOS® BM-C assesses the condition of the bushings based on changes in capacitance. The system compares the capacitance C1 of bushings obtained by very accurate voltage measurement with a precision capacitance CM which is specifically defined for each application. Breakdowns of the partial capacitances or even damage and aging of the internal insulation lead to changes in the capacitance which are signaled to the control center by the system as a warning or alarm.

MSENSE® BM-T / ETOS® BM-T assesses condition based on capacitance as well as loss factor (tan δ). As with MSENSE® BM-C / ETOS® BM-C, the capacitance is compared with the precision capacitance CM. In addition, MSENSE® BM-T / ETOS® BM-T considers the dissipation factor based on the calculated current vector from the reference voltage (line voltage). Changes of capacitance and dissipation factor indicate partial breakdowns of and damage to the internal insulation. In addition, damage to the conductor and the mechanical surface structure as well as heavy contamination can be detected. Also in this regard, the system provides the information as a warning or alarm to the control center.

The unique MR measuring principle: The patented algorithm eliminates environmental and operational influences. Since capacity and thus the loss factor can be changed by temporary environmental influences such as solar radiation, rain, snow and wind, and the loss factor can additionally be influenced by network asymmetries and load changes, MR's patented 2/3 reference algorithm always compares the values of the bushings in pairs. Changes in the comparison values therefore become apparent very quickly and, as a result, only changes that actually indicate aging and damage are detected. The advantages are obvious: MSENSE® BM / ETOS® BM precisely records the condition of each bushing without the need for additional sensors; the system is highly accurate and always available; and MSENSE® BM / ETOS® BM puts an end to false tripping of protective devices and transformer failures. It therefore protects your investment and ensures grid stability thanks to permanent monitoring.

*Higher voltage levels on request

We are here for you. Wherever you are.

Looking for the right contact partner?

Do you have a concern, but don't know whom you should contact? You will find that information in our contact overview. In the event of any technical disturbances, our 24/7 support is always at your disposal.

Welcome to myReinhausen

myReinhausen is MR's central, digital customer platform. On myReinhausen, customers can access customer-specific MR information as well as numerous free features related to the MR portfolio.

myReinhausenJoin Reinhausen family

Find your ideal job quickly!

Check our vacancies here. Apply today and contribute at the world market leader in energy technology keeping the energy supply stable in the future.