-

Impulses

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

- Lifetime optimization

- Power supply in industry

- Globalization

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

-

Lifetime optimization

-

Power supply in industry

-

Globalization

Impulses - Portfolio

-

Career

Career

-

Company

Company

Full control and intelligent regulation of transformers

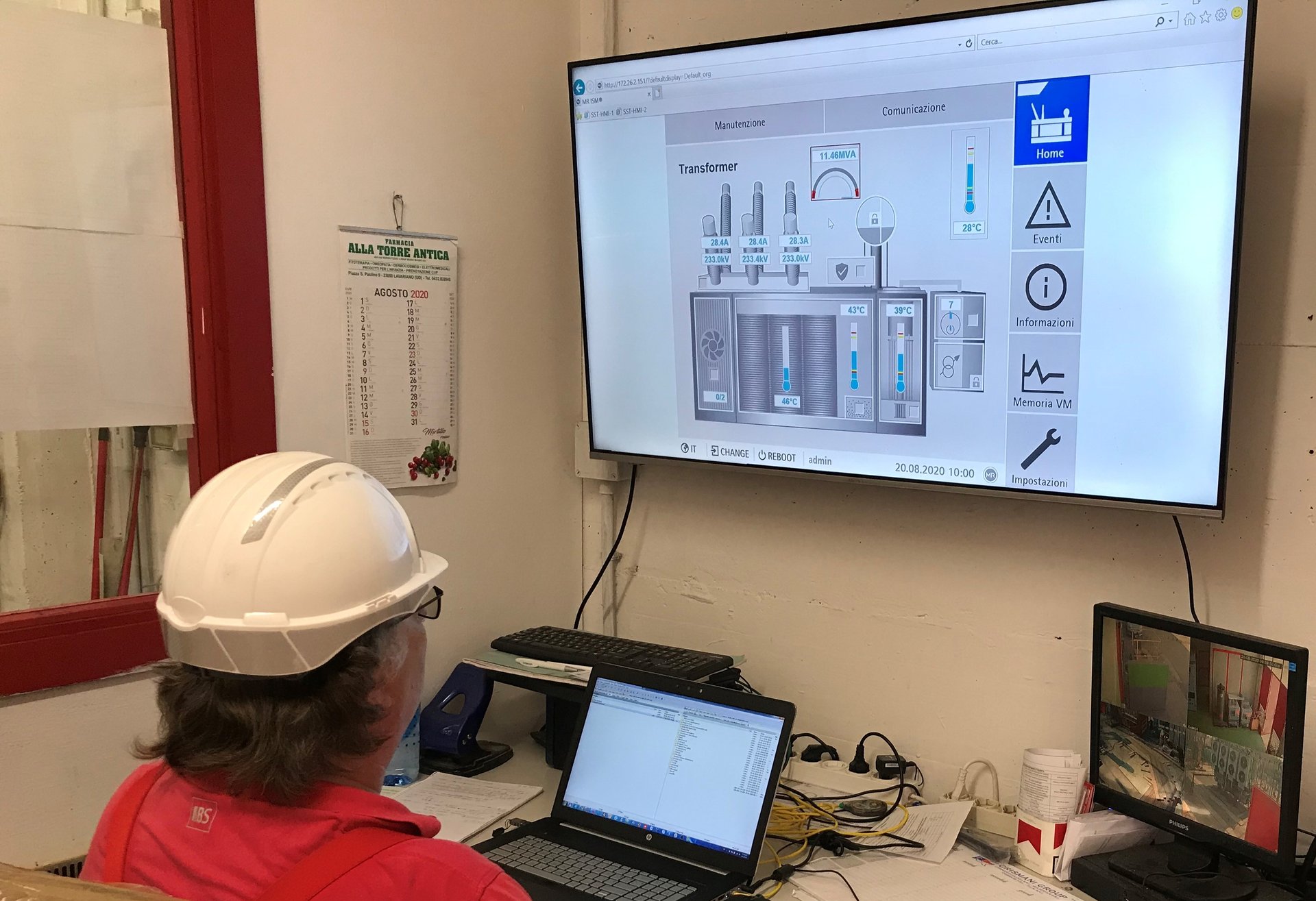

Italian steel producer ABS controls transformer station with ETOS®.

For the steel industry in particular, a loss of production is associated with enormous costs. To prevent its transformers from malfunctioning, the Italian steel company ABS (Acciaieria Bertoli Safau) carries out regular inspections. In order to have full control of the transformers even between maintenance intervals, ABS has now chosen an ETOS®, our open operating system for monitoring, controlling and regulating power transformers.

ABS has a large transformer station with four transformers. Every summer during the downtime period, the transformers undergo thorough inspections. However, the responsible staff of ABS want to have possibility to check status of their transformer also in the period between maintenance intervals and wanted to have a means of permanent monitoring. They turned to Reinhausen Italia (RI), which already performs on-load tap-changer maintenance for ABS as a service partner. The answer for ABS' demand was ETOS® (Embedded Transformer Operating System), the world's first open operating system for intelligent transformers. ETOS® is a system that can display and calculate various parameters for complete monitoring of all components of the transformer, such as those of the ventilator group, the bushings, the gas analysis system and, of course, the on-load tap-changer.

A big advantage is the modular design. As a result, we can make sure that future requirements can be easily covered by an appropriate installation. All functions of ETOS® can be purchased immediately or implemented subsequently. This allows the customer to manage his own budget according to actual current requirements.

The respectively installed firmware is capable of monitoring various parameters and calculating various data points based on the system configuration. This allows the operating personnel to ensure that the transformer is in flawless condition at all times. For example, it is possible to calculate a hot spot which can be used for calculation of life consumption of the transformer and it is also possible to record number of operation and value of thought current for calculation of wear consumption of the contacts (in case of using an OILTAP®) in the diverter switch.

ABS recognized the advantages immediately and ordered an ETOS® system for a transformer (72 MVA/primary voltage 220 kV) equipped with an OILTAP® M. The system selected by ABS has the following integrated functions:

- Monitoring of the PRO type diverter switch (with calculation of the wear on the diverter switch contacts and of the Motor Current Index (MCI))

- Monitoring of the PRO type transformer (with calculation of the remaining time of the transformer and calculation of the hot spot. Monitoring is already prepared for the calculation of additional parameters in case a sensor is installed for gas analysis, including for the boiling temperature of the oil and the moisture content in the paper)

- Checking and monitoring the cooling systems. The system automatically ensures the alternating operation of groups in order to equalize the operating hours. It also provides the option to start the two groups based on oil temperature or load and guarantees continuous functional monitoring of the fan propellers

- MSENSE® BM monitoring system of the high-voltage bushings with measurement of the capacitance value and of the dissipation factor using the 2/3 reference method

- Installation of the IEC 61850 protocol with GOOSE functionality and PRP redundancy using fiber-optic cables

- Visualization of all parameters over a connection to a web server and a special screen that is installed in the control room.

During the summer downtime in August, the work was carried out by Reinhausen Italia. The activities carried out included both mechanical work (installations in the control cabinet) and electrical work, such as the wiring of the various components of the transformer. Despite the demanding environmental conditions (with temperatures of up to 39 °C with increased humidity) as well as the restrictions due to the Corona pandemic, the work proceeded quickly, not least thanks to the energetic support of the ABS technicians and the external companies working for ABS. After the final functional tests and training for ABS employees, the project was successfully completed - the basis for future cooperation in transformer monitoring.

We are here for you. Wherever you are.

Looking for the right contact partner?

Do you have a concern, but don't know whom you should contact? You will find that information in our contact overview. In the event of any technical disturbances, our 24/7 support is always at your disposal.

Welcome to myReinhausen

myReinhausen is MR's central, digital customer platform. On myReinhausen, customers can access customer-specific MR information as well as numerous free features related to the MR portfolio.

myReinhausenJoin Reinhausen family

Find your ideal job quickly!

Check our vacancies here. Apply today and contribute at the world market leader in energy technology keeping the energy supply stable in the future.