MESSKO® MTRAB® 2.5

Maintenance-free dehydrating breathers

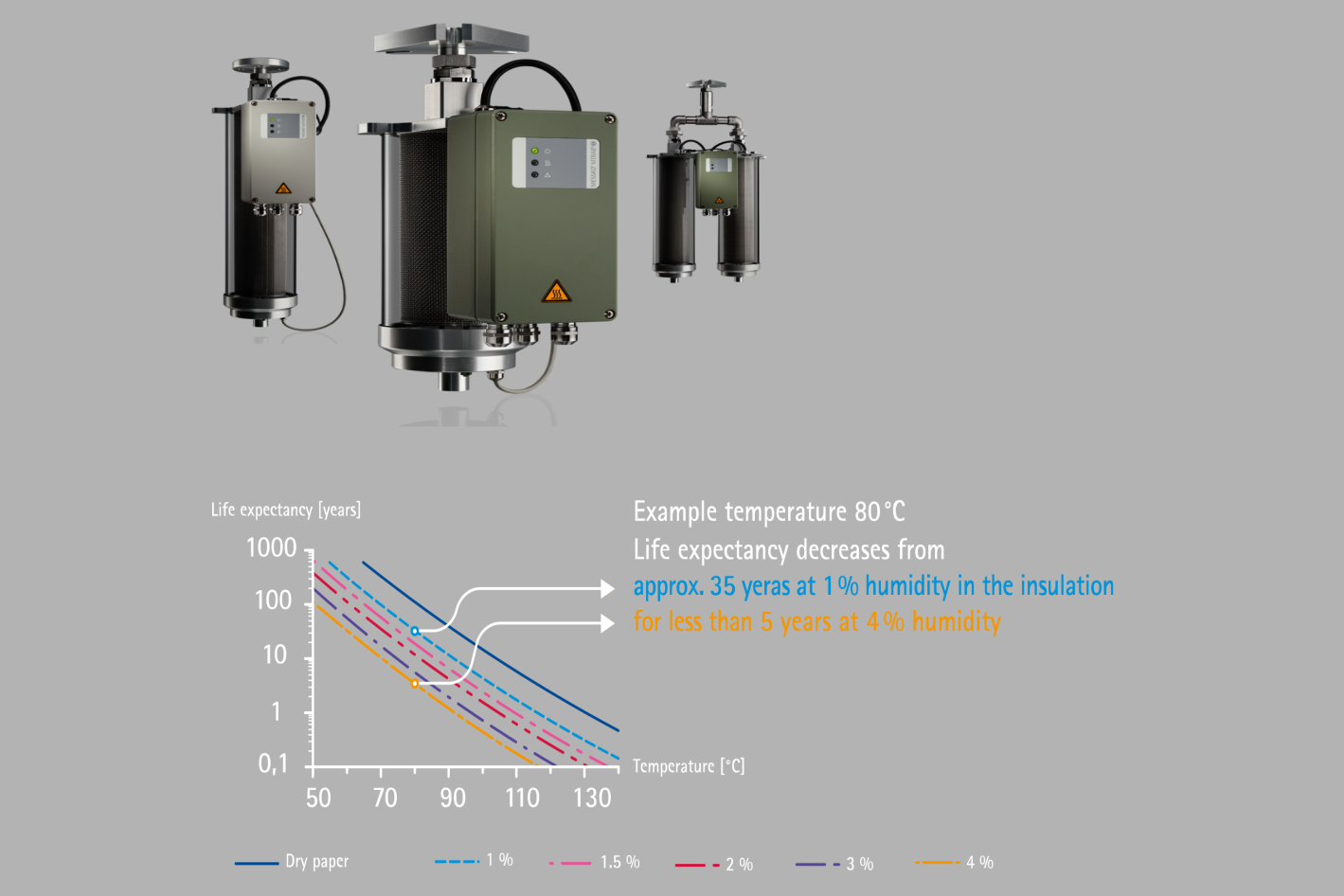

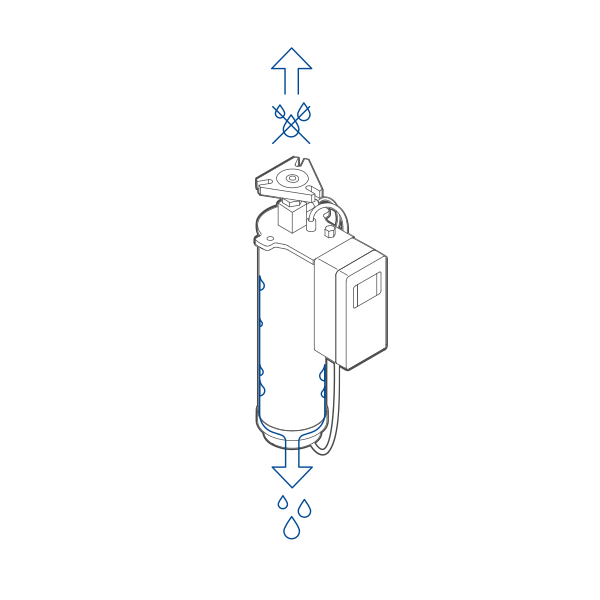

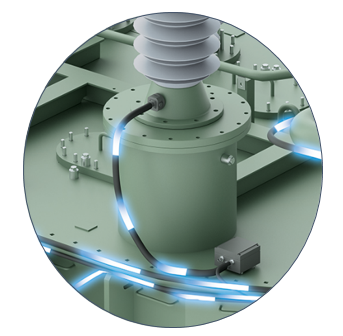

Ever longer operating times and ever higher current densities lead to constantly increasing demands on operating equipment. The maintenance-free MESSKO® MTRAB® 2.5 dehydrating breathers continuously dehumidify and monitor the breathing cycle of power transformers – in all climatic zones. They regenerate themselves. This ensures maximum operating times and safety, and also massively reduces costs. The MESSKO® MTRAB® 2.5 devices have been proven over 90,000 times worldwide. The intelligent algorithm ensures that the IEC 60076-22-7 standard is complied with at all times. The MESSKO® MTRAB® 2.5 now offers an app function for easy data transfer.

Your Advantages at a Glance

-

Reduces operating costs and increases operational reliability

-

Actively protects the insulation medium against humidity

-

Condition-dependent and self-learning algorithm

-

Significantly higher efficiency than market competitors

-

Easy to integrate into ETOS® – Embedded Transformer Operating System

-

Simple to retrofit on existing equipment

-

Successful around the world and fit for the future in accordance with IEC 60076-22-7

-

With new app function for easy readout of data

Product Information

| APPLICATION | MTRAB® 2.5-type | SILICA GEL |

| Tap changer | DB100 | 1,1 kg |

| Arc suppression coil (Petersen coil) | DB100 | 1,1 kg |

| Air-filled cable terminal boxes | DB100 | 1,1 kg |

| Traction transformers | DB100 | 1,1 kg |

| Network transformers ≤40 MVA | DB100T | 1,1 kg |

| Phase shifters ≤ 40 MVA | DB100T | 1,1 kg |

| Reactors ≤ 40 MVA | DB100T | 1,1 kg |

| Network and step-up transformers > 40 MVA ≤ 200 MVA | DB200T | 2,2 kg |

| Phase shifters > 40 MVA ≤ 200 MVA | DB200T | 2,2 kg |

| Reactors > 40 MVA ≤ 200 MVar | DB200T | 2,2 kg |

| Generator and network coupling transformers 200 MVA | DB200D or 2 x DB200T | 4,4 kg |

| Phase shifters > 200 MVA | DB200D or 2 x DB200T | 4,4 kg |

| Reactors > 200 MVar | DB200D or 2 x DB200T | 4,4 kg |

| HVDC transformers | DB200D or 2 x DB200T | 4,4 kg |

| Furnace transformers | DB200G | 2 x 2,2 kg |

| Cavern transformers | DB200G | 2 x 2,2 kg |

| GSU machine transformers | DB200G | 2 x 2,2 kg |

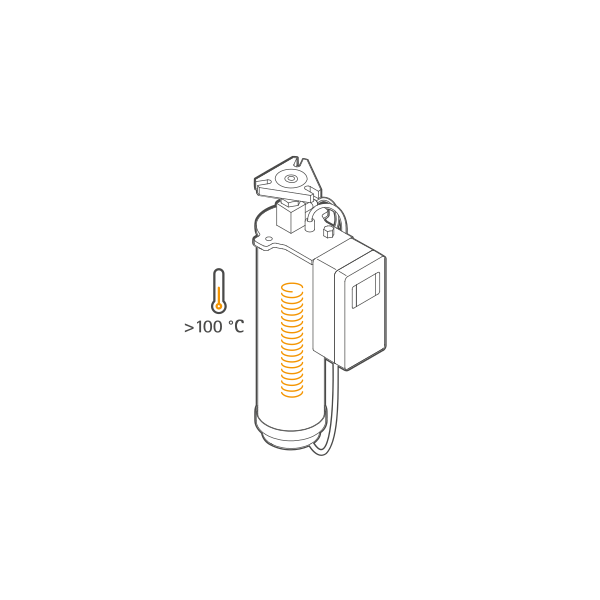

The MTRAB® 2.5 DB100 with alpha-control is a condition-controlled system, recommended for use on tap changers, arc suppression coils, air-filled cable terminal boxes and traction transformers. The desiccant is regenerated depending on the condition. Silica gel fill level: 1,1 kg with α-control.

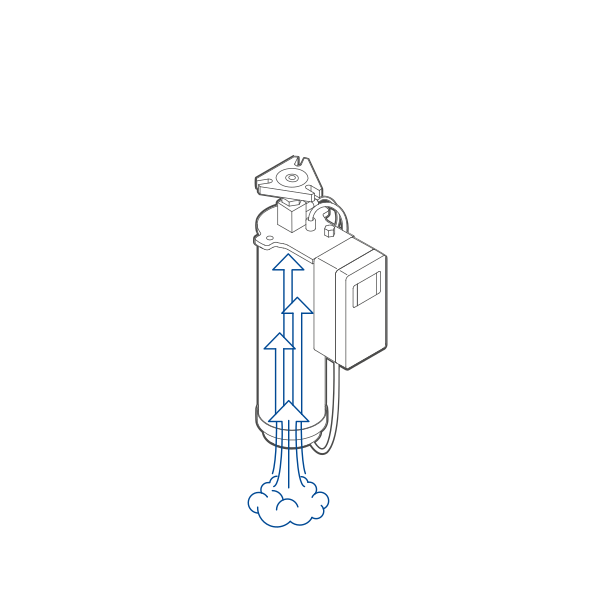

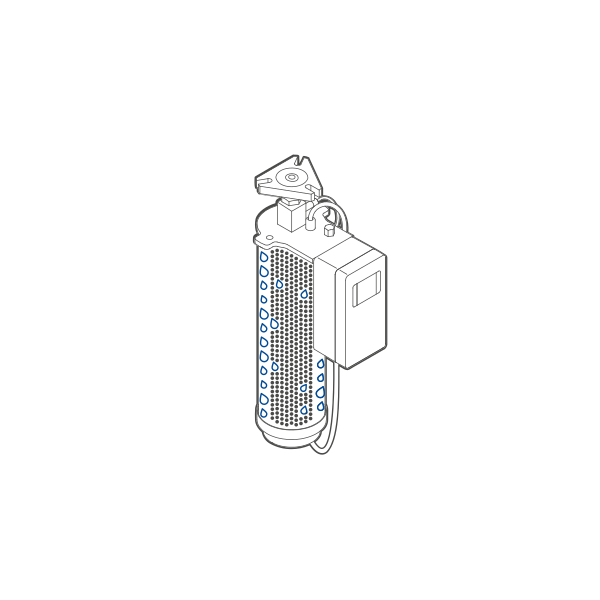

Good to know: The main function of dehydrating breathers is to dehumidify the ambient air. As a result of the thermal compression of the insulation medium, the ambient air flows from the environment to the expansion tank of the transformer and tap changer (referred to as inhalation). During inhalation, moisture must be prevented from penetrating into the equipment with the air flow, as this reduces the insulating effect due to the contamination of the insulating medium.

The MTRAB® 2.5 DB100T with beta-control is a self-learning system, recommended for use on transformers with cyclic loads (network transformers, phase shifters, reactors). In addition to monitoring the humidity, the device determines a time window in which the oil conservator exhales and the desiccant is regenerated. Silica gel fill level: 1,1 kg with β-control.

Good to know: The main function of dehydrating breathers is to dehumidify the ambient air. As a result of the thermal compression of the insulation medium, the ambient air flows from the environment to the expansion tank of the transformer and tap changer (referred to as inhalation). During inhalation, moisture must be prevented from penetrating into the equipment with the air flow, as this reduces the insulating effect due to the contamination of the insulating medium.

The MTRAB® 2.5 DB200T with beta-control is a self-learning system, recommended for use on transformers with cyclic loads (network transformers, step-up transformers, phase shifters, reactors). In addition to monitoring the humidity, the device determines a time window in which the oil conservator exhales and the desiccant is regenerated. Silica gel fill level: 2,2 kg with β-control.

Good to know: The main function of dehydrating breathers is to dehumidify the ambient air. As a result of the thermal compression of the insulation medium, the ambient air flows from the environment to the expansion tank of the transformer and tap changer (referred to as inhalation). During inhalation, moisture must be prevented from penetrating into the equipment with the air flow, as this reduces the insulating effect due to the contamination of the insulating medium.

The MTRAB® 2.5 DB200D with beta-control is a self-learning system, recommended for use on transformers with cyclic loads (generator transformers, network coupling transformers, phase shifters, reactors, HVDC transformers). In addition to monitoring the humidity, the device determines a time window in which the oil conservator exhales and the desiccant is regenerated. Silica gel fill level: 2 x 2,2 kg with β-control.

Good to know: The main function of dehydrating breathers is to dehumidify the ambient air. As a result of the thermal compression of the insulation medium, the ambient air flows from the environment to the expansion tank of the transformer and tap changer (referred to as inhalation). During inhalation, moisture must be prevented from penetrating into the equipment with the air flow, as this reduces the insulating effect due to the contamination of the insulating medium.

The MTRAB® 2.5 DB200G with gamma-control is ideal for special applications, such as cavern transformers, furnace transformers and GSU machine transformers with aperiodic breathing behaviors. If the humidity level in the air flowing towards the transformer exceeds the standardized value, the desiccant chambers are regenerated in sequence. Silica gel fill level: 2 x 2,2 kg with γ-control.

Good to know: The main function of dehydrating breathers is to dehumidify the ambient air. As a result of the thermal compression of the insulation medium, the ambient air flows from the environment to the expansion tank of the transformer and tap changer (referred to as inhalation). During inhalation, moisture must be prevented from penetrating into the equipment with the air flow, as this reduces the insulating effect due to the contamination of the insulating medium.

Software

The MESSKO® MTRAB® 2.5 is equipped with a data logger of the latest generation as standard (software optional). The MTRAB® MSET software allows to monitor and analyze the device function and processes (dehumidification and regeneration) at any time. This provides additional safety when monitoring the equipment. In addition, you benefit from the long-term analysis – recording of the important operating parameter residual air humidity over a period of up to 10 years.

Available languages: English, Chinese, French, German, Italian, Korean, Portuguese, Russian and Spanish

MESSKO® MTRAB® App

With the app, you can easily read out the entire data memory of your device on your smartphone. This requires that your MESSKO® MTRAB® 2.5 is equipped with NFC (Near Field Communication) and Bluetooth®. With this quick and easy connection between MESSKO® MTRAB® and smartphone, you can read out the data even without a notebook and can read out the last two days of the MESSKO® MTRAB® even when there is no power supply.

Everything important always at a glance:

- Detailed information on device status (online and offline) plus error description with recommendations for action.

- Graphical display of the trend of humidity and temperature

- Creation of reports

- GPS position of the location where the device is read out

Free download:

App Store

Google Play

Available languages: English, German, and from 2023: Spanish, French, Italian, Korean, Portuguese and Chinese

Select language

| APPLICATION | MTRAB® 2.5-type | SILICA GEL |

| Tap changer | DB100 | 1,1 kg |

| Arc suppression coil (Petersen coil) | DB100 | 1,1 kg |

| Air-filled cable terminal boxes | DB100 | 1,1 kg |

| Traction transformers | DB100 | 1,1 kg |

| Network transformers ≤40 MVA | DB100T | 1,1 kg |

| Phase shifters ≤ 40 MVA | DB100T | 1,1 kg |

| Reactors ≤ 40 MVA | DB100T | 1,1 kg |

| Network and step-up transformers > 40 MVA ≤ 200 MVA | DB200T | 2,2 kg |

| Phase shifters > 40 MVA ≤ 200 MVA | DB200T | 2,2 kg |

| Reactors > 40 MVA ≤ 200 MVar | DB200T | 2,2 kg |

| Generator and network coupling transformers 200 MVA | DB200D or 2 x DB200T | 4,4 kg |

| Phase shifters > 200 MVA | DB200D or 2 x DB200T | 4,4 kg |

| Reactors > 200 MVar | DB200D or 2 x DB200T | 4,4 kg |

| HVDC transformers | DB200D or 2 x DB200T | 4,4 kg |

| Furnace transformers | DB200G | 2 x 2,2 kg |

| Cavern transformers | DB200G | 2 x 2,2 kg |

| GSU machine transformers | DB200G | 2 x 2,2 kg |

The MTRAB® 2.5 DB100 with alpha-control is a condition-controlled system, recommended for use on tap changers, arc suppression coils, air-filled cable terminal boxes and traction transformers. The desiccant is regenerated depending on the condition. Silica gel fill level: 1,1 kg with α-control.

Good to know: The main function of dehydrating breathers is to dehumidify the ambient air. As a result of the thermal compression of the insulation medium, the ambient air flows from the environment to the expansion tank of the transformer and tap changer (referred to as inhalation). During inhalation, moisture must be prevented from penetrating into the equipment with the air flow, as this reduces the insulating effect due to the contamination of the insulating medium.

The MTRAB® 2.5 DB100T with beta-control is a self-learning system, recommended for use on transformers with cyclic loads (network transformers, phase shifters, reactors). In addition to monitoring the humidity, the device determines a time window in which the oil conservator exhales and the desiccant is regenerated. Silica gel fill level: 1,1 kg with β-control.

Good to know: The main function of dehydrating breathers is to dehumidify the ambient air. As a result of the thermal compression of the insulation medium, the ambient air flows from the environment to the expansion tank of the transformer and tap changer (referred to as inhalation). During inhalation, moisture must be prevented from penetrating into the equipment with the air flow, as this reduces the insulating effect due to the contamination of the insulating medium.

The MTRAB® 2.5 DB200T with beta-control is a self-learning system, recommended for use on transformers with cyclic loads (network transformers, step-up transformers, phase shifters, reactors). In addition to monitoring the humidity, the device determines a time window in which the oil conservator exhales and the desiccant is regenerated. Silica gel fill level: 2,2 kg with β-control.

Good to know: The main function of dehydrating breathers is to dehumidify the ambient air. As a result of the thermal compression of the insulation medium, the ambient air flows from the environment to the expansion tank of the transformer and tap changer (referred to as inhalation). During inhalation, moisture must be prevented from penetrating into the equipment with the air flow, as this reduces the insulating effect due to the contamination of the insulating medium.

The MTRAB® 2.5 DB200D with beta-control is a self-learning system, recommended for use on transformers with cyclic loads (generator transformers, network coupling transformers, phase shifters, reactors, HVDC transformers). In addition to monitoring the humidity, the device determines a time window in which the oil conservator exhales and the desiccant is regenerated. Silica gel fill level: 2 x 2,2 kg with β-control.

Good to know: The main function of dehydrating breathers is to dehumidify the ambient air. As a result of the thermal compression of the insulation medium, the ambient air flows from the environment to the expansion tank of the transformer and tap changer (referred to as inhalation). During inhalation, moisture must be prevented from penetrating into the equipment with the air flow, as this reduces the insulating effect due to the contamination of the insulating medium.

The MTRAB® 2.5 DB200G with gamma-control is ideal for special applications, such as cavern transformers, furnace transformers and GSU machine transformers with aperiodic breathing behaviors. If the humidity level in the air flowing towards the transformer exceeds the standardized value, the desiccant chambers are regenerated in sequence. Silica gel fill level: 2 x 2,2 kg with γ-control.

Good to know: The main function of dehydrating breathers is to dehumidify the ambient air. As a result of the thermal compression of the insulation medium, the ambient air flows from the environment to the expansion tank of the transformer and tap changer (referred to as inhalation). During inhalation, moisture must be prevented from penetrating into the equipment with the air flow, as this reduces the insulating effect due to the contamination of the insulating medium.

Software

The MESSKO® MTRAB® 2.5 is equipped with a data logger of the latest generation as standard (software optional). The MTRAB® MSET software allows to monitor and analyze the device function and processes (dehumidification and regeneration) at any time. This provides additional safety when monitoring the equipment. In addition, you benefit from the long-term analysis – recording of the important operating parameter residual air humidity over a period of up to 10 years.

Available languages: English, Chinese, French, German, Italian, Korean, Portuguese, Russian and Spanish

MESSKO® MTRAB® App

With the app, you can easily read out the entire data memory of your device on your smartphone. This requires that your MESSKO® MTRAB® 2.5 is equipped with NFC (Near Field Communication) and Bluetooth®. With this quick and easy connection between MESSKO® MTRAB® and smartphone, you can read out the data even without a notebook and can read out the last two days of the MESSKO® MTRAB® even when there is no power supply.

Everything important always at a glance:

- Detailed information on device status (online and offline) plus error description with recommendations for action.

- Graphical display of the trend of humidity and temperature

- Creation of reports

- GPS position of the location where the device is read out

Free download:

App Store

Google Play

Available languages: English, German, and from 2023: Spanish, French, Italian, Korean, Portuguese and Chinese

Select language

The dehydrating breather for transformers and tap-changers from the market leader

| Effectively prevent moisture in the insulation medium |

| LOWERING OPERATING EXPENSES, EXTENDING SERVICE LIFE |

| 90,000 times tested and proven worldwide – even under the most extreme conditions. |

| MESSKO® MTRAB® 2.5 is a tried and tested system – fit for the future in accordance with IEC 60076-22-7. |

| Technology from the market leader: dehumidifies and continuously monitors the respiratory cycle of the power transformer. Considerable cost savings. |

The latest technology for optimum operation and reduced operating Ccosts

The latest technology for optimum operation and reduced operating Ccosts

- Data logger incl. software (software optional)

- Extended overvoltage protection in accordance with EN 60664-1 Category III

- IP66/IP67 degree of protection

- Corrosion protection C4H or CX in accordance with IEC 12944

- Test button for manually checking the function, moisture level at the device output and message chains (included as standard)

- Direct integration into monitoring and SCADA systems

- Prepared for integration into ETOS® (optional)

Maximizing operating times and reliability. Increasing efficiency.

Maximizing operating times and reliability. Increasing efficiency.

- Ever-longer operating times and ever-greater current densities lead to continuously increasing demands on equipment.

- Optimal dehydration is the essential prerequisite for the health of your equipment.

- The proven solution: the maintenance-free MESSKO® MTRAB® 2.5

Advantages over conventional solutions

| MESSKO® MTRAB® 2.5 DEHYDRATING BREATHER | CONVENTIONAL DEHYDRATING BREATHERS |

| + A significant increase in operational reliability thanks to the maintenance-free system | - High risk for transformers if maintenance is not or is improperly carried out |

| + The lack of required maintenance means visual inspections can be reduced to a minimum. | - Regular visual inspection required throughout the entire service life of the transformer to check the moisture level of the desiccant |

| + Cost-intensive, regular replacement of the desiccant is no longer necessary. This significantly reduces costs. | - Regular replacement of the desiccant required throughout the entire service life of the transformer |

| + Sensor- and status-controlled regeneration of the silica gel | - Enormous costs due to frequent refilling of desiccant, in particular in regions with high humidity |

| + No environmental or disposal problems arising from consumed desiccant | - Environmental impact, disposal problems, and considerable costs due to consumed desiccant |

| + Greater efficiency during dehydration thanks to the large contact surface and the technical design | - Ineffective dehydration |