MSENSE® FO

Fiber-optic online temperature measurement with the MSENSE® FO system

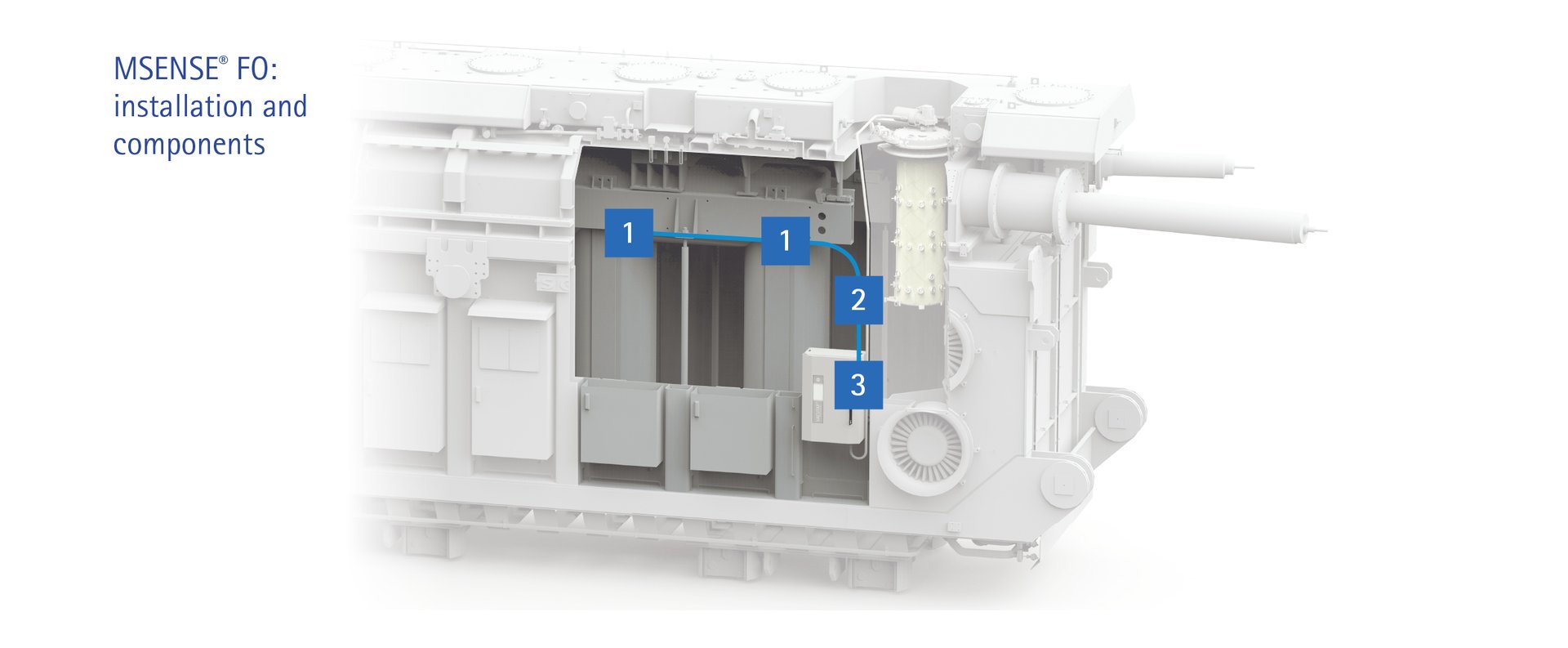

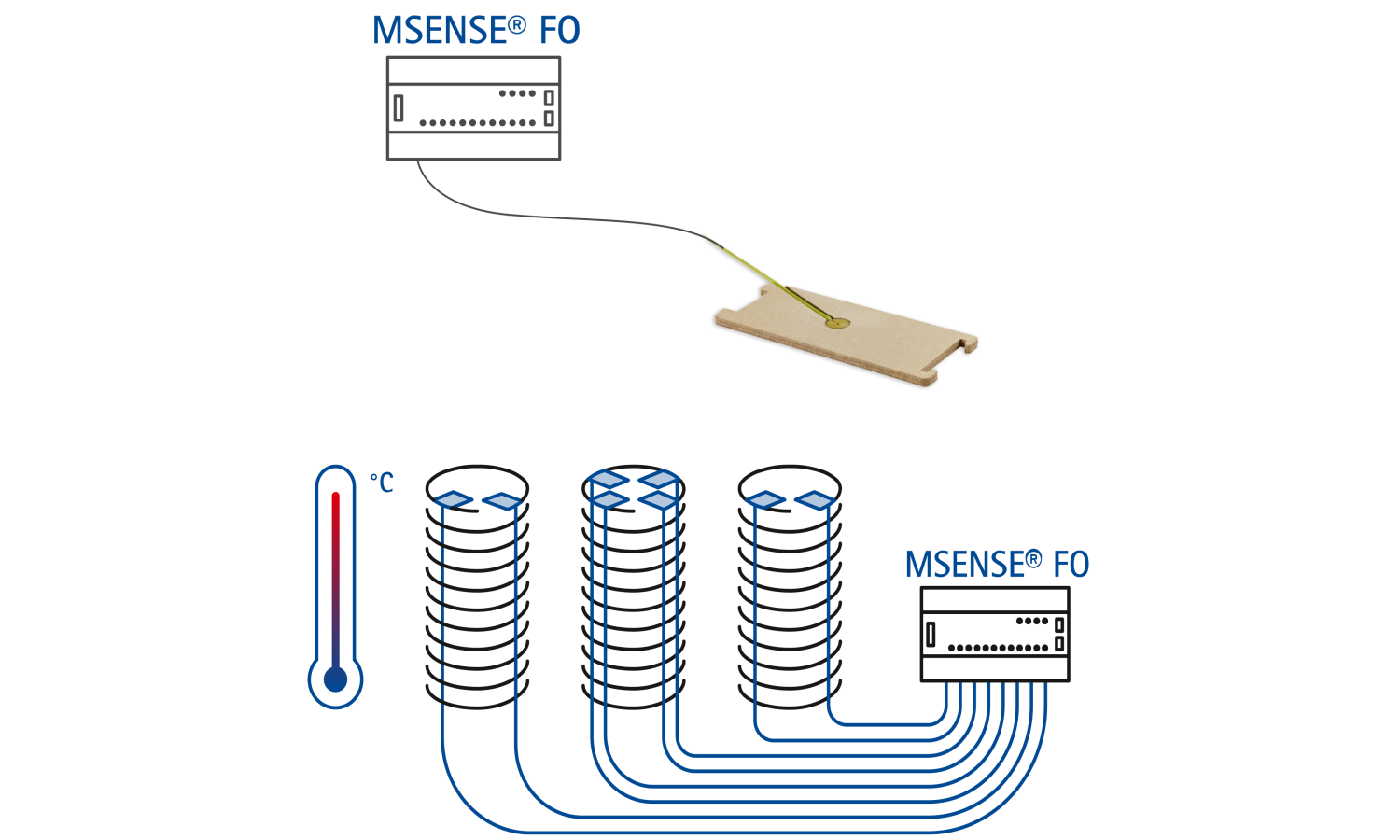

When power transformers fail, the costs can get high. Online fiber optic temperature monitoring by MSENSE® FO precisely detects the winding temperature in real time. Unlike conventional measurements, the system immediately detects a rise in winding temperature or hot spot. It is easy to integrate, robust and comprehensively processes the measured values. MSENSE® FO is the effective tool for dynamic overload management and ensures high operational reliability and efficiency.

Your Advantages at a Glance

-

Continuous, real-time recording of the winding temperature

-

Early detection of potential hotspots, enabling service-life management

-

Effective overload management with ETOS®

-

Maximum reliability and availability through internal reference sensor

-

Easy integration into the design and value chain of a power transformer

-

Connection to SCADA

Product Information

Monitoring the thermal loads with MSENSE® FO while also using ETOS® safeguards grid stability and enables responses to dynamic overloads. Monitoring the winding temperature online provides the basis for improved temperature management and, at the same time, enables data-based service-life and asset management. The interplay between MSENSE® FO and ETOS® is preconfigured and fits into the world's first open operating system for intelligent transformers. A connection to SCADA systems common throughout the world is also available as an option.

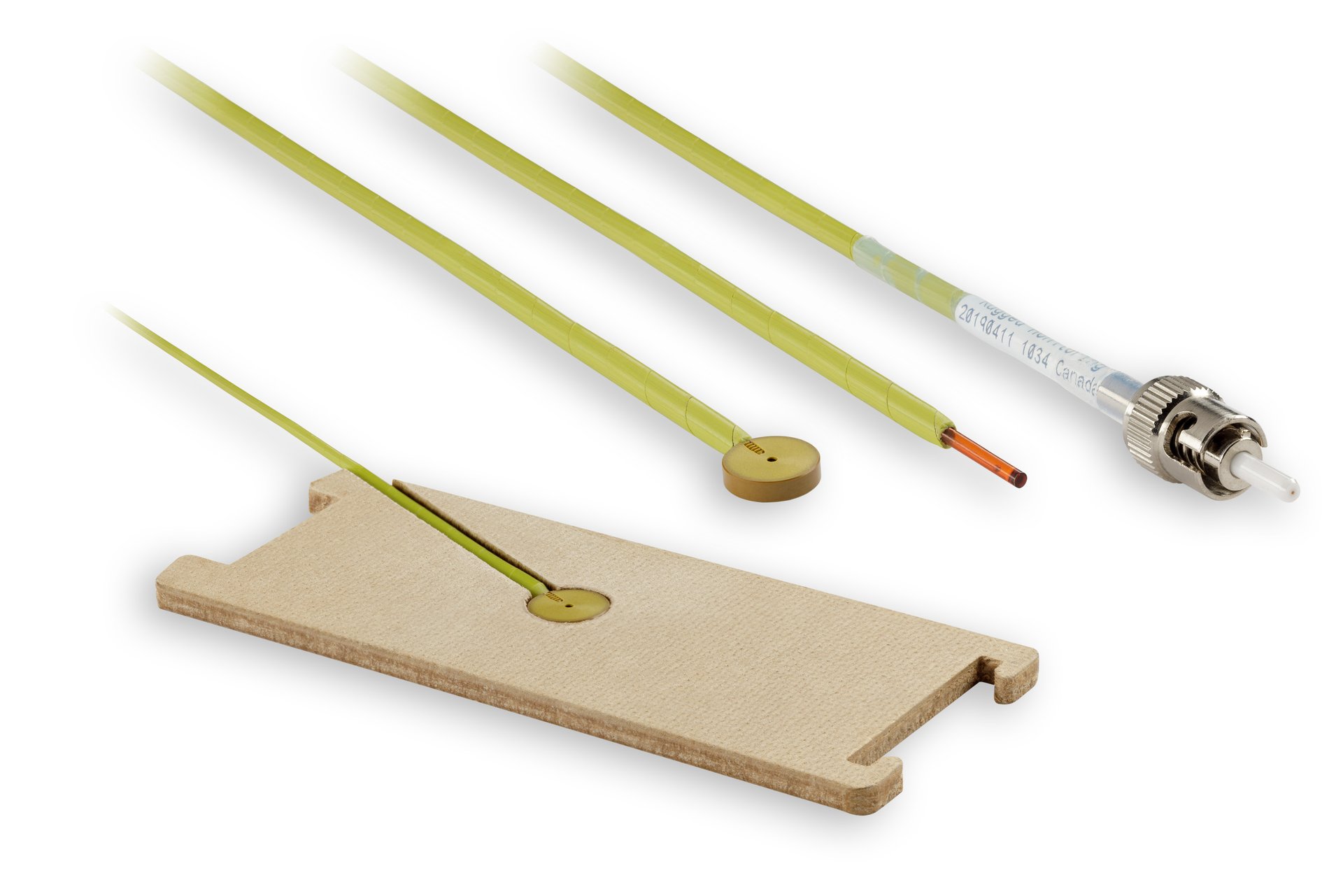

Based on many years of practical field experience and industry-leading expertise, details have been integrated into the fiber-optic sensor that fit seamlessly into the design and the value chain of a power transformer.

The user-optimized solution goes beyond the requirements of ASTM D3426 and D-149, and has a very low partial discharge (< 2 pC).

The use of first-class materials combined with high-quality production and testing technology also ensures a coherent and field-optimized overall concept for the add-on accessories. This not only fits seamlessly into the design and value chain, but also takes the environment and application into account to the highest degree.

The symbiosis of optimized sensor technology with sophisticated electronics and data preparation is integrated into a customer-oriented overall solution.

Depending on the application and application requirements, you can choose between different versions and optional extensions.

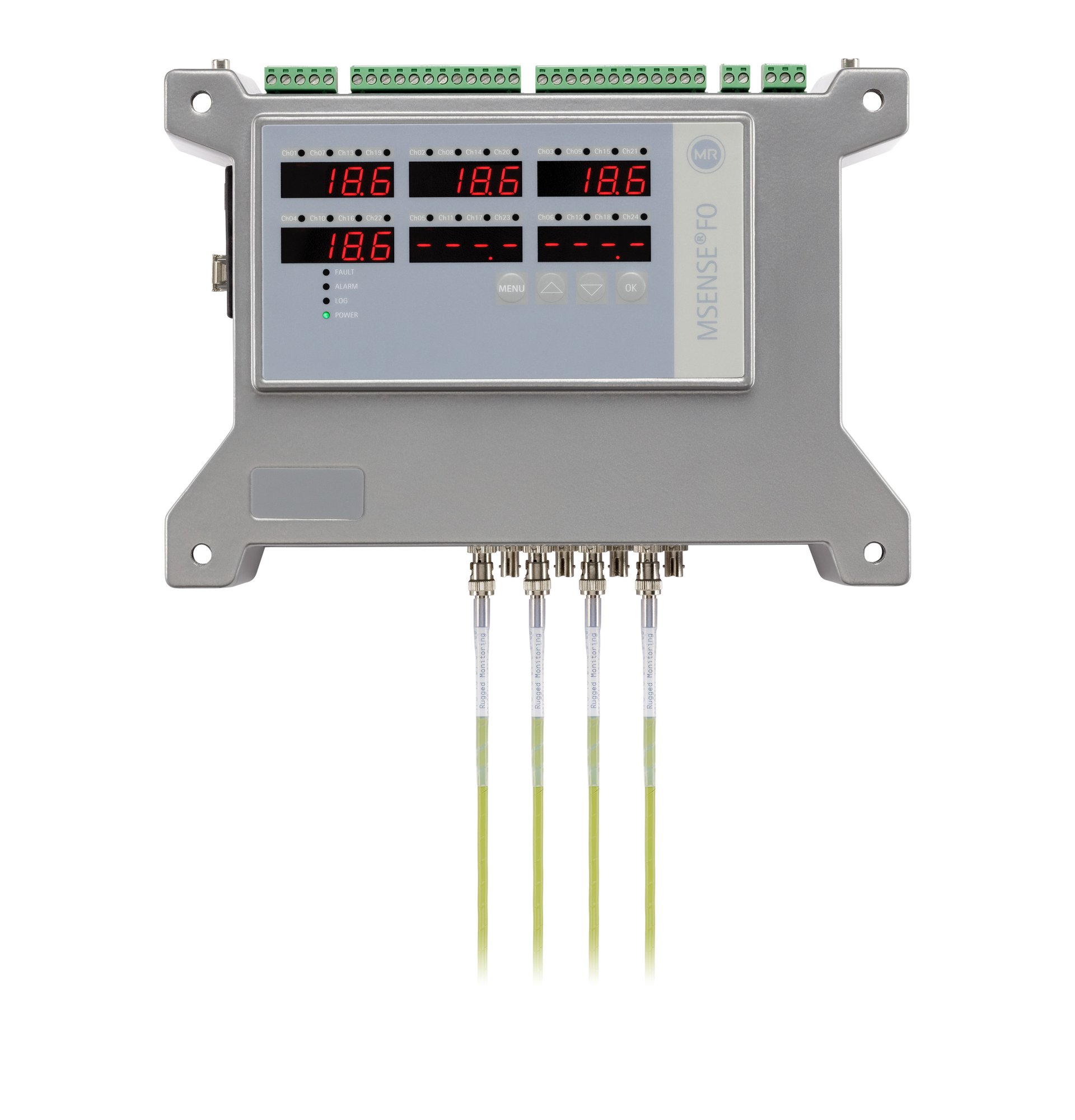

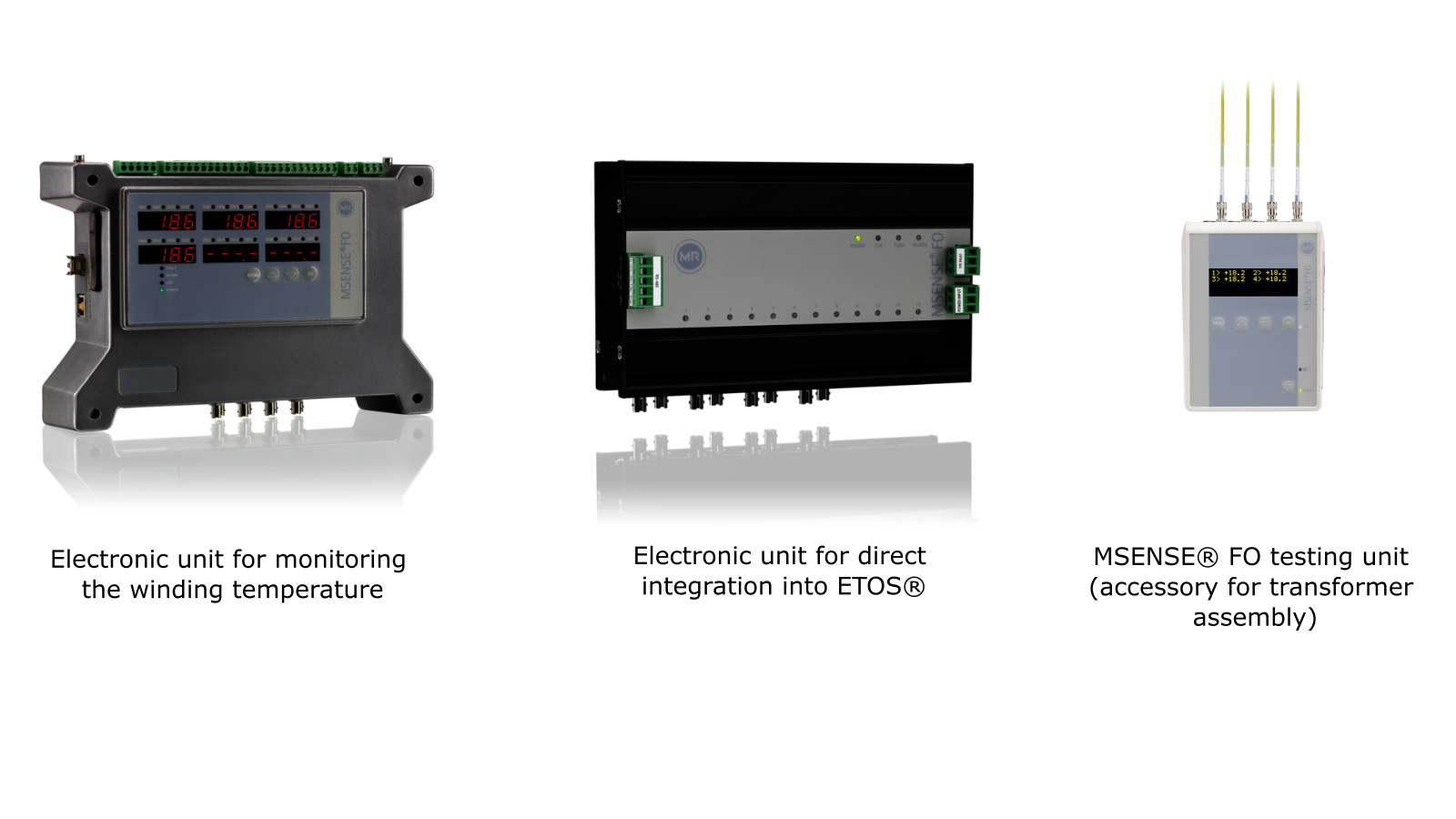

Stand-alone solution: MSENSE® FO ECU-S

Integration into ETOS®: MSENSE® FO ECU-I

(Both with MSET FO evaluation software)

Select language

Monitoring the thermal loads with MSENSE® FO while also using ETOS® safeguards grid stability and enables responses to dynamic overloads. Monitoring the winding temperature online provides the basis for improved temperature management and, at the same time, enables data-based service-life and asset management. The interplay between MSENSE® FO and ETOS® is preconfigured and fits into the world's first open operating system for intelligent transformers. A connection to SCADA systems common throughout the world is also available as an option.

Based on many years of practical field experience and industry-leading expertise, details have been integrated into the fiber-optic sensor that fit seamlessly into the design and the value chain of a power transformer.

The user-optimized solution goes beyond the requirements of ASTM D3426 and D-149, and has a very low partial discharge (< 2 pC).

The use of first-class materials combined with high-quality production and testing technology also ensures a coherent and field-optimized overall concept for the add-on accessories. This not only fits seamlessly into the design and value chain, but also takes the environment and application into account to the highest degree.

The symbiosis of optimized sensor technology with sophisticated electronics and data preparation is integrated into a customer-oriented overall solution.

Depending on the application and application requirements, you can choose between different versions and optional extensions.

Stand-alone solution: MSENSE® FO ECU-S

Integration into ETOS®: MSENSE® FO ECU-I

(Both with MSET FO evaluation software)

Select language

FIBER-OPTIC ONLINE TEMPERATURE MEASUREMENT WITH THE MSENSE® FO SYSTEM

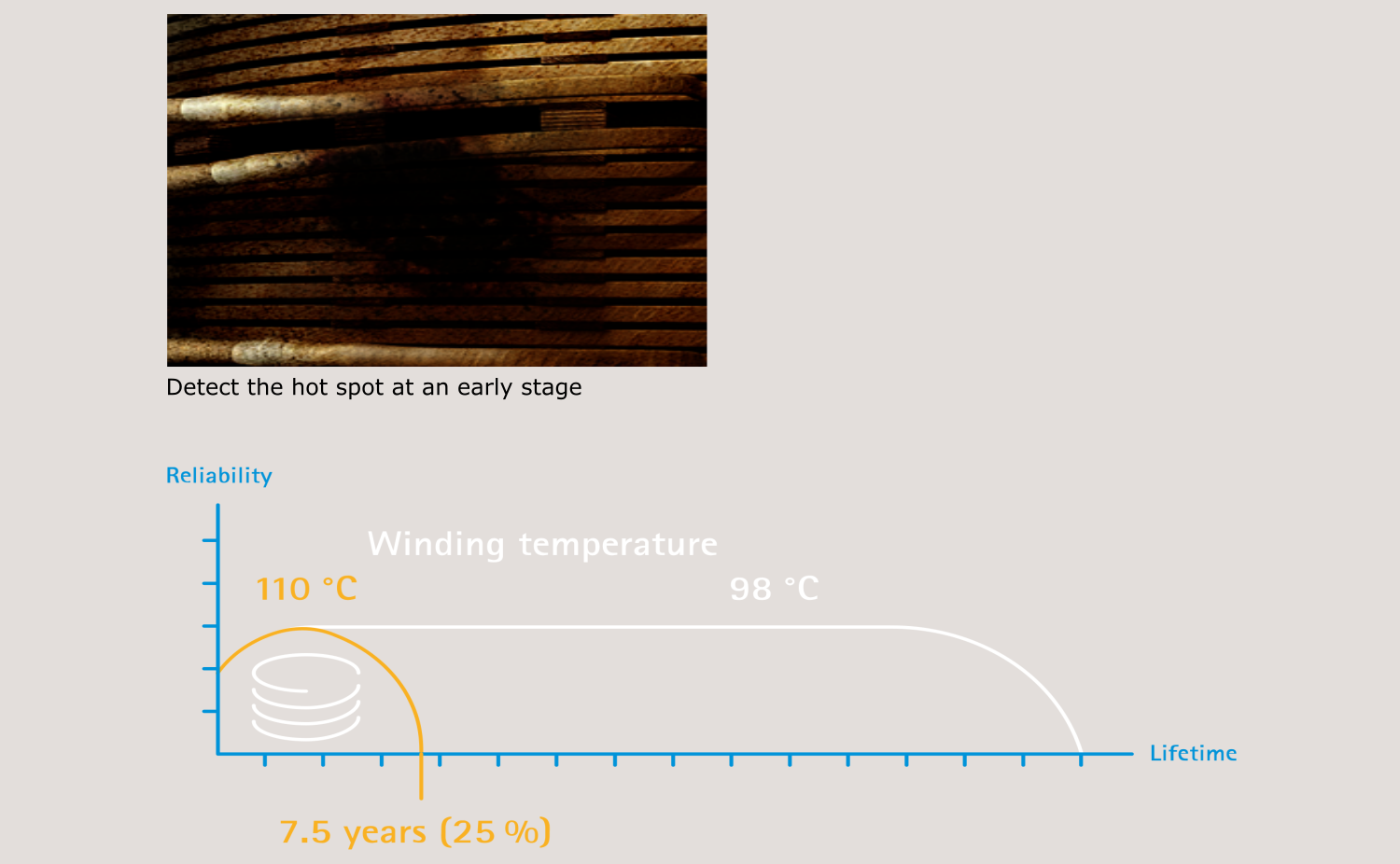

| Detect hot spots directly at the source |

| FOR A QUANTIFIABLY LONGER SERVICE LIFE |

12°CIncreases in the winding temperature drastically reduce the service life of the transformer by 75 %. |

| MSENSE® FO provides a modular system for optimal temperature management. |

| Maximum efficiency as well as overload and service-life management, in combination with ETOS®. |

power transformer failures are extremely costly

precise overload management guarantees a long service life and efficient operation

precise overload management guarantees a long service life and efficient operation

- According to a study by CIGRE*, winding problems are the cause of up to 45% of transformer failures.

- An increase of just 12 °C in the winding temperature drastically reduces the service life of the transformer by 75%.

- Conventional winding-temperature thermometers only offer a calculated, average depiction of the temperature profile.

- For critical and important applications in particular, precise and effective temperature management is key.

- And that is exactly why we developed the fiber-optic MSENSE® FO system.

*The Conseil International des Grands Réseaux Électriques, or International Council on Large Electric Systems, is a collaborative global community committed to the world’s leading knowledge development program for the creation and sharing of power system expertise.

the early warning system for a long service life

the early warning system for a long service life

- Online monitoring of the winding temperature forms the basis for optimal temperature management.

- The MSENSE® FO system accurately depicts the winding temperature continuously in real time.

- It shows the thermal state of the transformer at all times.

- As an early warning system, MSENSE® FO provides operational security and ensures a long service life.

- Monitoring of thermal loads with MSENSE® FO while also using ETOS® guarantees grid stability and enables responses to dynamic overloads.