-

Impulses

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

- Lifetime optimization

- Power supply in industry

- Globalization

- Impulses overview

-

Transformer manufacturers

- South America's champions of the energy transition

- Traction Transformers – Future on the Rail

- Time of the giants: XXL transformers for more power

- "Reinhausen is ready to deliver!"

- Oversized de-energized tap-changers

- The most powerful transformers in the world for a 1,100 kV HVDC line in China

- "We are in a growth market with the VRDT"

- Digitalization turnaround: GANZ Intelligent Solutions relies on cooperation with MR

- "Transitioning to a solution provider presents a major opportunity for transformer manufacturers – and digitalization can help!"

-

Digitalization

- How AI can lend a hand

- myReinhausen: MR's central digital customer platform

- Why data centers (may) never fail

- Automation? (Cyber-) Secure!

- Globally unique: MESSKO® MTRAB® dehydrating breather communicates via cell phone app

- Remote Solutions: Professional help from a distance

- "Digitalization of the power grids will only work with comprehensive security measures"

- Why are you digitizing your transformers? Three questions for Rúnar Svavar Svavarsson.

- Six challenges, six solutions – Intelligent sensors for safe transformers

-

Energy transition

- The VRDT is the ideal solution to solve voltage problems in our distribution grids

- Making transformers more sustainable

- 940 tons of power regulation

- Sunny prospects: Municipal solar storage devices

- Four reasons why regulated distribution grids are the future

- "The energy transition is taking place in the distribution grids"

- Five theses on the future of power grids

- Storage at all network levels

- Test systems for the energy revolution

- Climate change, energy revolution and the future of power grids?

- A new design for utility poles

-

Wind and solar power

- The North Sea as Europe's green power plant

- Sahara electricity - safe for the island

- Are wind farms the new power plants?

- Direct current at all grid levels

- The MSCDN plant – the new "power plant generator" for stable grids

- Clean power grid with high-frequency filters

- Weatherproof cable testing for offshore wind parks

- VRDTs for Australia's distribution grids

-

Lifetime optimization

-

Power supply in industry

-

Globalization

Impulses - Portfolio

-

Career

Career

-

Company

Company

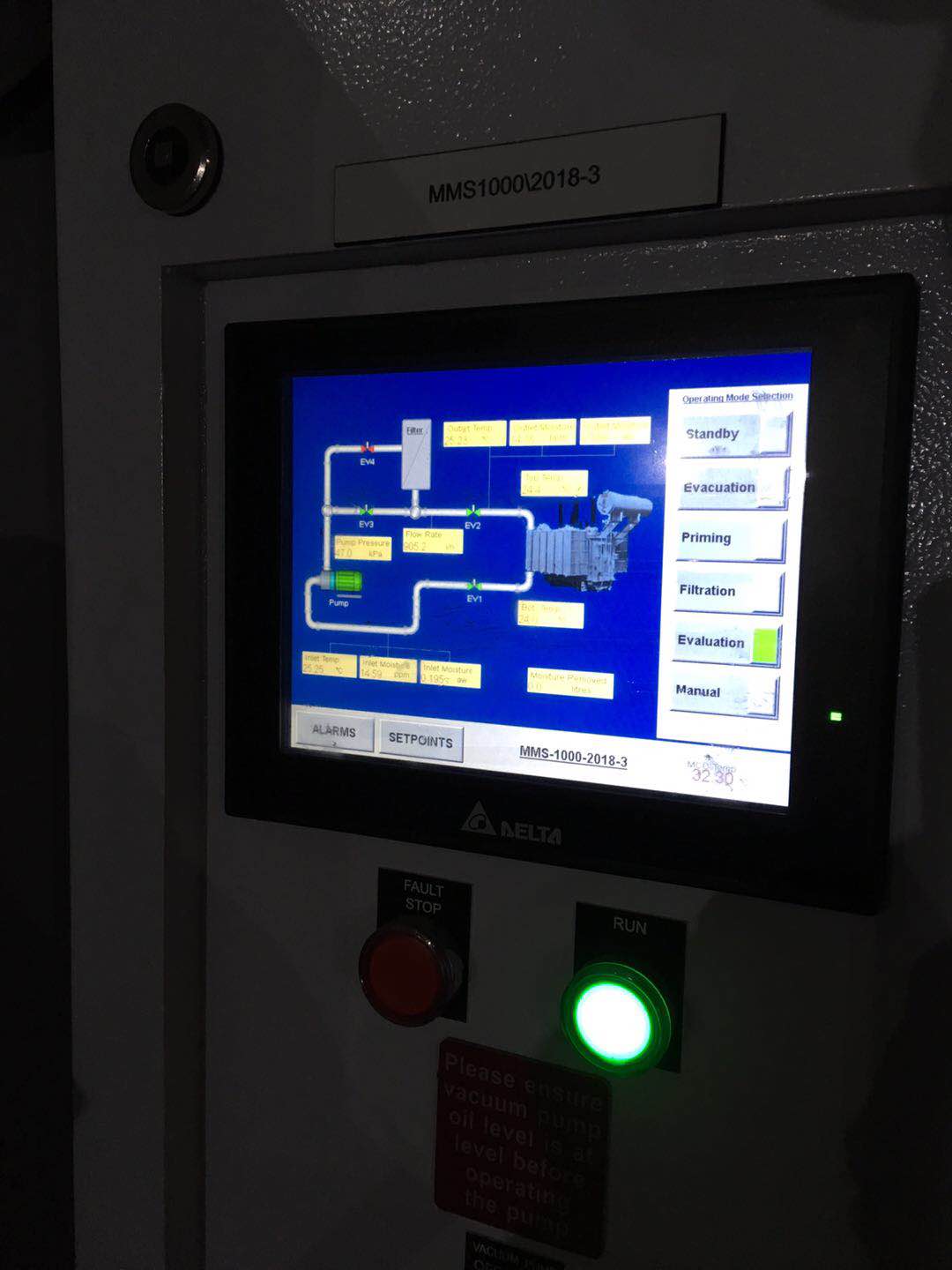

Intelligent Transformer Drying

The MR EXPIOTECH MMS Moisture Management System prevents premature failure of transformers at a steel works

Alongside increased winding and oil temperatures, the moisture content in the oil is one of the most critical factors that can massively shorten the service life of a transformer, since both temperature and moisture can damage the paper insulation and therefore also have a negative effect on the thermal insulating properties. A Chinese steel works experienced this first hand at the end of 2018, when moisture levels triggered early warnings. Thanks to the MR EXPIOTECH MMS Moisture Management System, they were able to reduce the moisture content and prevent their transformers from failing prematurely.

A Chinese steel works had operated three 22,000 kVA/35 kV furnace transformers for more than five years. However, since commissioning, the three transformers had not undergone regular maintenance or diagnostic measurements. In the fall of 2018, oil analyses were finally carried out, the results of which showed that the moisture and acetylene contents in the oil of all three power transformers significantly exceeded the relevant standards. This caused their dielectric strength to drop, which triggered the aforementioned early warning signals on two of the transformers.

Those in charge therefore decided upon comprehensive maintenance for these two transformers, during which one transformer would be shut off while the other two continued to keep operations running. During maintenance, the service technicians determined, among other things, that a lot of water had collected on the bottom of the transformer tank, that the iron core was accordingly rusty, and that the insulation resistance to ground was too low. The two transformers suffered from different levels of damage, which could be traced back to the irregular performance of maintenance and diagnostics.

The steel works operator decided to take measures to combat this in advance before the third transformer also triggered an early warning. To reduce the moisture content effectively and thus avoid damage to the transformer, it is important to determine and reduce the moisture not just in the oil, but also in the insulating paper. Due to the dynamic equilibrium and the unequal distribution of moisture content, this requires a special drying method. For this purpose, the operator chose innovative MR technology. The new MR EXPIOTECH Moisture Management System was put to use for the first time in China, removing 4.3 L of water from the paper over an extended period during continuing operation.

The main advantage of our new EXPIOTECH MMS can be found in its intelligent drying concept. Multiple sensors for moisture detection, together with algorithms we developed ourselves, measure the moisture content in the paper very precisely and use this information to determine the optimal target value and the duration of the drying procedure. This ensures that sufficient moisture is extracted while preventing over-drying and a related loss of contact pressure in the windings. In addition, this means that the history of the transformer remains almost completely preserved, since water but not gasses is extracted by the special filter.

The intelligent drying concept used by the MR EXPIOTECH system ensures precision, optimization and complete control. It helps us ensure that transformers run smoothly and that the electric power supply and electric supply network become more solid and reliable. For this purpose, we fall back on our many years of experience. After more than 15 years and 600 successful drying procedures in our home market, EXPIOTECH® is now also available worldwide.

| m.foata@reinhausen.com |

We are here for you. Wherever you are.

Looking for the right contact partner?

Do you have a concern, but don't know whom you should contact? You will find that information in our contact overview. In the event of any technical disturbances, our 24/7 support is always at your disposal.

Welcome to myReinhausen

myReinhausen is MR's central, digital customer platform. On myReinhausen, customers can access customer-specific MR information as well as numerous free features related to the MR portfolio.

myReinhausenJoin Reinhausen family

Find your ideal job quickly!

Check our vacancies here. Apply today and contribute at the world market leader in energy technology keeping the energy supply stable in the future.