TESSA® APM

The next level for your asset management

As an asset performance management software, TESSA® APM supports the planning of maintenance measures and investments through standardized and consistent calculations. Both online and offline data serve as a basis, which you record, for example during your inspections or manual measurements. With help of algorithms and Artificial Intelligence we are building digital twins.

TESSA® APM adapts to your wishes and needs by combining modules individually and according to your requirements. In addition, with the help of a high-performance database, you have insight into historical and current trends and receive concrete recommendations for action for your entire transformer fleet.

Your Advantages at a Glance

-

Reliable condition assessment

Monitor and evaluate the condition of all assets using selected interpretations

-

Access to expert knowledge

Make use of MR experts’ evaluation standards

-

Easy setup and handling

Use comprehensible, standardized software application that can be individually configured by user

-

Extension of lifetime | Reduction of CAPEX and OPEX

Get automatic calculation and visualization of indices for detection and intervention in critical conditions

-

Support for your ISO 55.000 process

Benefit from the basis for further budget and investment planning

Product Information

Focus on the relevant assets and optimize your maintenance

The requirements for asset management are constantly increasing. Failure of your critical assets has significant financial, legal and safety implications and creates economic challenges for the customers you serve. Aging transformer fleets, a heterogeneous fleet of manufacturers, years of manufacturing, pre-loads, as well as high-cost pressure, require ever-more precise planning to prevent costly and image-damaging system failures.

A comprehensive and transparent determination of the condition of the equipment is imperative for proactively planning maintenance and required investments as well as carrying out these tasks at the right time. Which equipment data should be collected, and how can economically feasible decisions be reached based on this data?

In TESSA® Asset Performance Management (APM), data collected from both online and offline sources are combined, stored in a central database and displayed on any device with clear, user-friendly responsive designs. Understandable uniform and configurable interpretations allow users to determine the condition of assets automatically while harnessing the power of artificial intelligence and MR’s experts for recommended actionable next steps. These evaluations enable meaningful condition assessments of the operating equipment and form a reliable basis for precise budget and investment planning. As such, they make valuable contribution to implanting ISO 55000 requirements.

TESSA® APM opens a new dimension for economically feasible investment planning and asset maintenance.

Select language

Focus on the relevant assets and optimize your maintenance

The requirements for asset management are constantly increasing. Failure of your critical assets has significant financial, legal and safety implications and creates economic challenges for the customers you serve. Aging transformer fleets, a heterogeneous fleet of manufacturers, years of manufacturing, pre-loads, as well as high-cost pressure, require ever-more precise planning to prevent costly and image-damaging system failures.

A comprehensive and transparent determination of the condition of the equipment is imperative for proactively planning maintenance and required investments as well as carrying out these tasks at the right time. Which equipment data should be collected, and how can economically feasible decisions be reached based on this data?

In TESSA® Asset Performance Management (APM), data collected from both online and offline sources are combined, stored in a central database and displayed on any device with clear, user-friendly responsive designs. Understandable uniform and configurable interpretations allow users to determine the condition of assets automatically while harnessing the power of artificial intelligence and MR’s experts for recommended actionable next steps. These evaluations enable meaningful condition assessments of the operating equipment and form a reliable basis for precise budget and investment planning. As such, they make valuable contribution to implanting ISO 55000 requirements.

TESSA® APM opens a new dimension for economically feasible investment planning and asset maintenance.

Select language

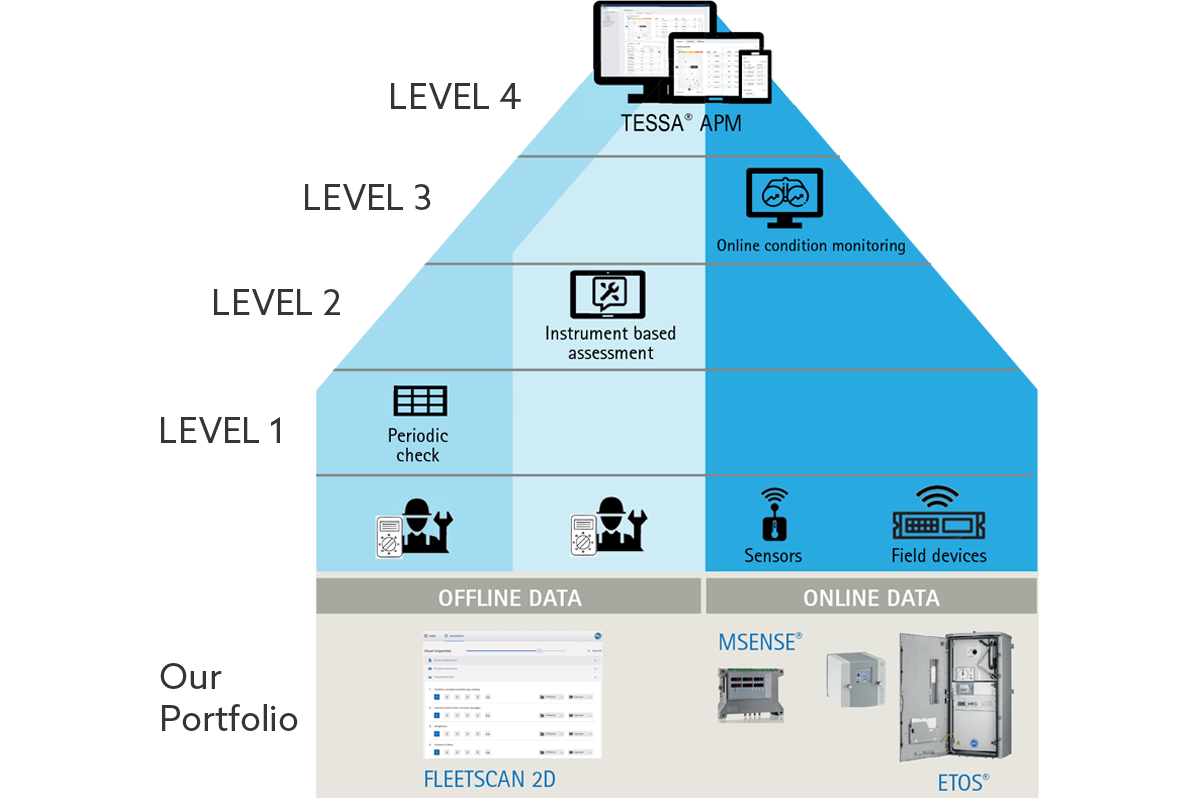

Unite the online and offline data of your transformer

Unite the online and offline data of your transformer

LEVEL 4: Predictive maintenance

- Automated algorithms & artificial intelligence

- Combination of all online, offline and individual data

- Access to expert knowledge

LEVEL 3: Condition monitoring and information

- Supervision of asset trends

- 24/7 measurements

LEVEL 2: Individual measurements

- Integration of experts knowledge

- Deep analysis of the assets

LEVEL 1: On-site inspections

- Standard manual measurements

- Noted abnormalities

A user-story to tell

A user-story to tell

1) Imagine you are in meeting and you get a call from a colleague: red alert! Something has happened… What to do now?

2) Remember that you have TESSA® APM! Using your mobile device, you get the first overview about what has occurred at your asset.

3) In your office, you have a closer look in TESSA® APM on your computer to get a clearer understanding of what has happened. You see a recommendation of what to do and start the service process.

4) The service technician arrives at the correct substation of the affected transformer with all the right tools on hand.

5) The service technician reviews the asset issues in his tablet or laptop and performs the defined service actions.

6) When the service technician has done his job and you are still in the office, you see your asset condition change back to “green” again!

Access TESSA® APM wherever you are and with any device

Desktop: Full overview, all functions and all details

Notebook: Get the relevant information at hand and dive deeper as wished

Mobile: Get most important info at a glance

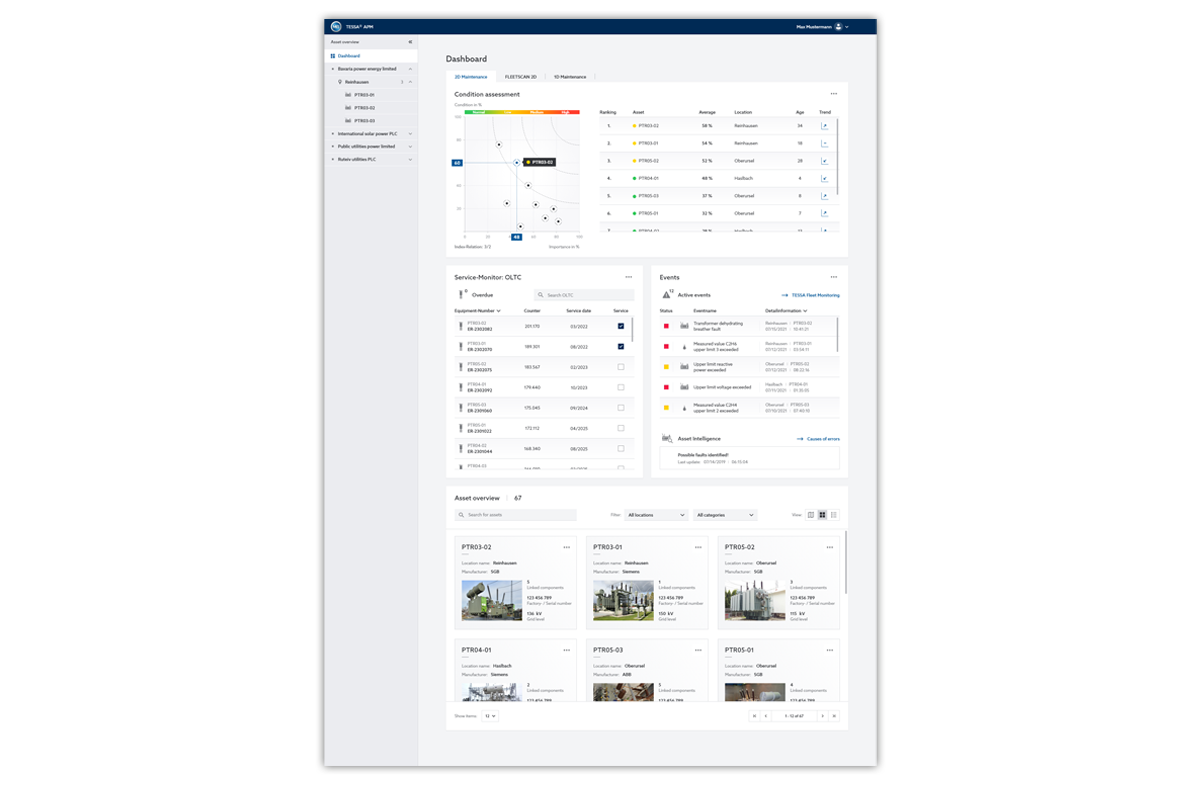

Dashboard

Dashboard

Transformer details: All your information where it should be

- Identify where you need to act and understand what is happening

- Start your maintenance planning

Service Monitor: All your OLTCs at a glance

- Understand the service needs and due times of all your OLTCs

- Has a service been done and which OLTCs’ services can be combined to safe money and time?

Asset Ranking: Compare the overall health in your fleet

- Gain the overview over the actual health of your assets

- Understand how the status changed in the past (trend)

Real-time monitoring

Real-time monitoring

TESSA® Fleet monitoring: 24/7 online monitoring of success critical assets

- Connect sensors for continuous data transfer or import sensor data manually

- Apply flexible analysis to sensor data

- Detect critical conditions

- Receive automated interpretation of events

Asset intelligence: From data acquisition to data-based measures

- Use the existing data as simple basic inputs

- Benefit from our unique algorithms and artificial intelligence to get a holistic and automated evaluation (cross-sensor/-equipment)

- Get focused and reliable action recommendations with indications and contra-indications

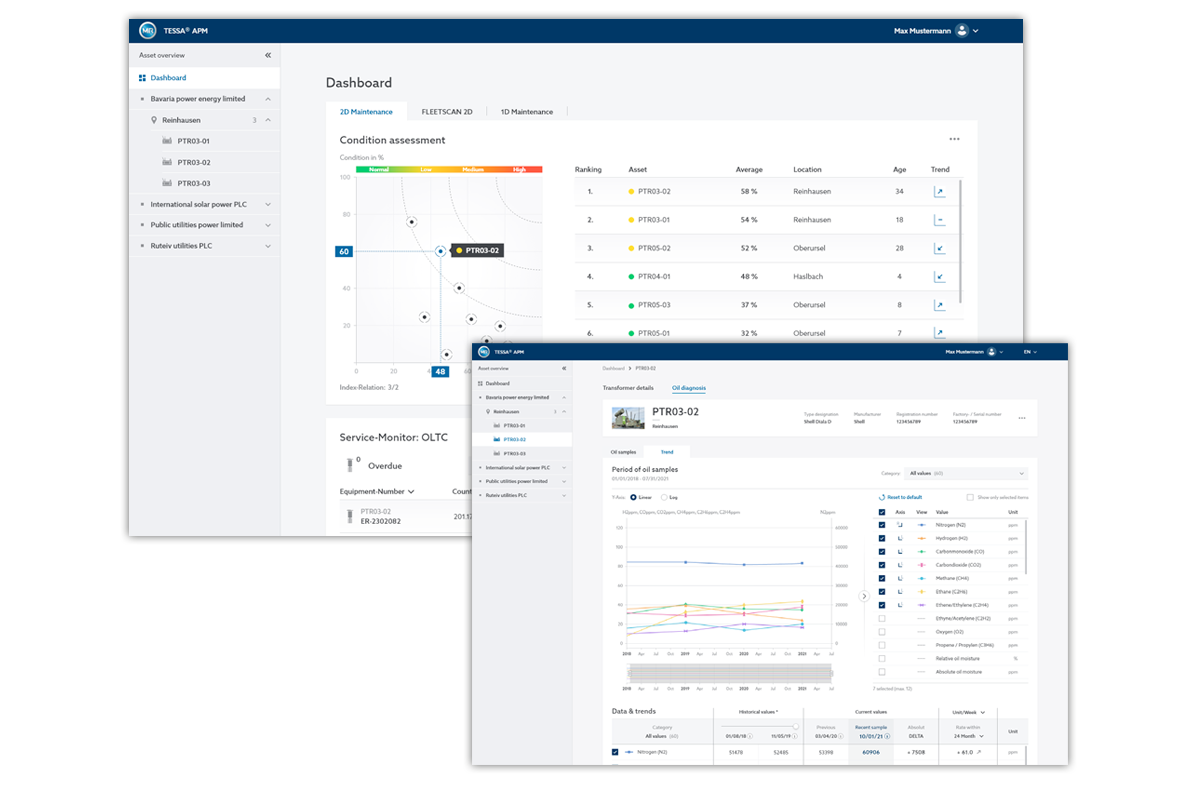

Condition assessment

Condition assessment

Health index: Reliable evaluation standards

- Combine various data sources (including offline and online data)

- Configure weighted indices for condition, risks and importance to reflect your asset management philosophy

- Compare to reliable indices defined by MR according to industry standards and expert knowledge

TESSA® Fleetscan 2D: Expert condition assessment by MR

- Collect data from visual inspections and offline measurements directly in the field

- Unique condition assessment based on knowledge of MR experts

- Receive clearand prioritized recommendations for service actions

Oil diagnosis: In depth analysis for the most critical transformer part

- Gather all data from lab reports

- Flexible trend charts on all relevant categories

- Compare actual values to limits (IEEE, Cigre, individual and more) and analyze by industry standards (Duval, Rogers, IEC60599 and more)